Sterilizing method of trypsin inhibitor

A technology of trypsin inhibition and sterilization method, which is applied in the field of sterilization of trypsin inhibitor products, can solve the problems of difficult membrane cleaning, small processing capacity, expensive equipment, etc., achieve good sterilization effect, large processing capacity, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1. Pressure sterilization of trypsin inhibitor and its microbial detection

[0040] Several different protein powders were made into a 50 mg / ml solution, centrifuged at 1000 × g for 30 min at 5°C, and the supernatant was divided into two parts, one for the determination of trypsin activity and microbial indicators. The other part was pressurized for 60 min under the conditions of 600MPa and 25°C, and the activity of trypsin inhibitor and microbial indicators were determined. Among them, the total number of colonies is carried out with reference to the GB / T 4789.2-2003 detection method; the total number of coliforms is carried out with reference to the GB / T 4789.3-2003 testing method; the mold and yeast are carried out with reference to the GB / T 4789.1 5-2003 testing method. The test results are shown in Table 1.

[0041] In Table 1, sweet potato crude protein is the sweet potato crude protein prepared by the above method, wherein the protein content is about 70...

Embodiment 2

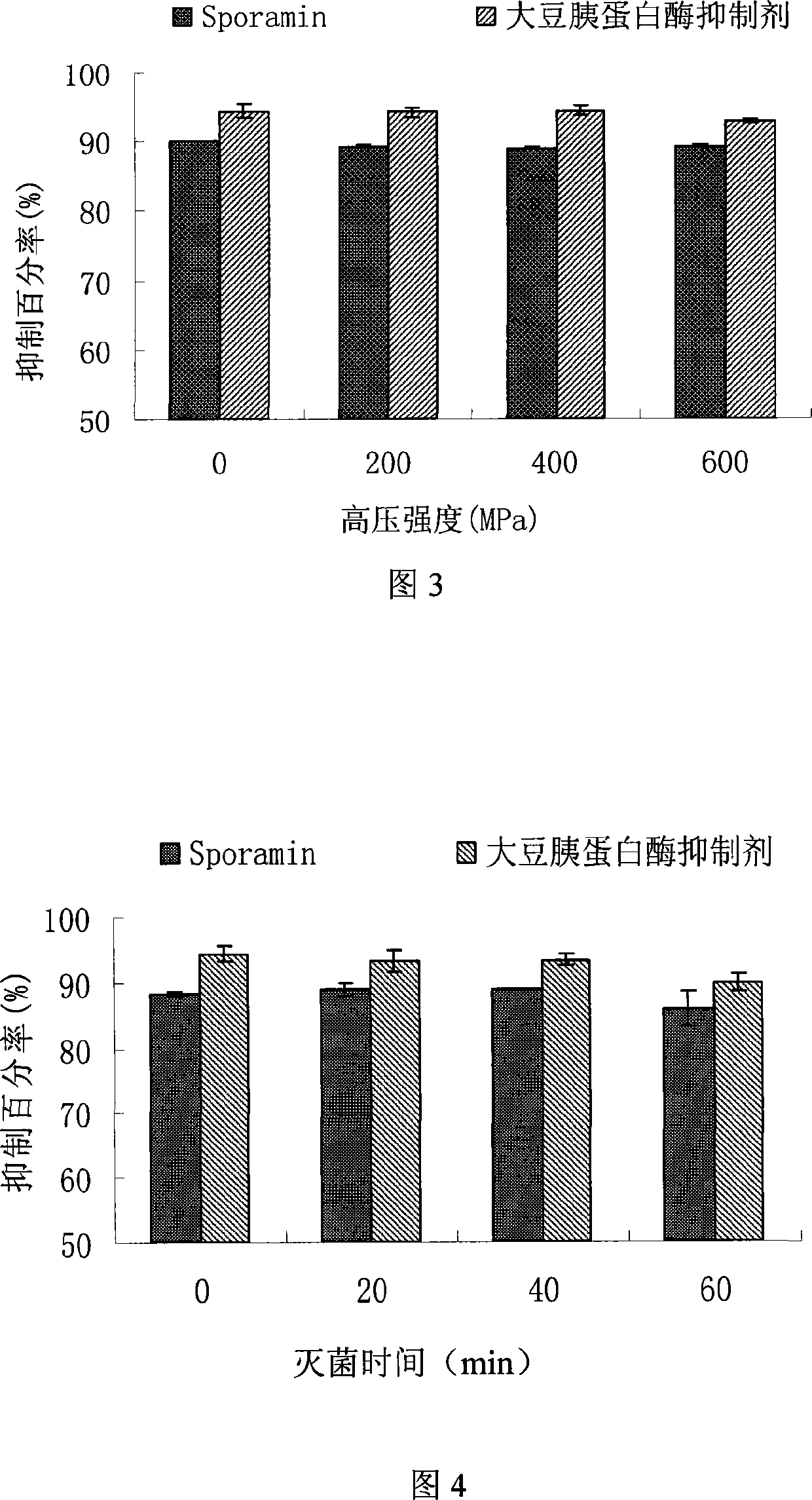

[0045] Example 2. Effect of trypsin inhibitor concentration on its activity during sterilization

[0046] The purified sweet potato protein Sporamin was diluted into 3, 2, 1, 0.6, 0.3, 0.2, 0.15, 0.1 mg / ml solutions with different concentrations, and kept at 600 MPa and 25 °C for 20 min. active.

[0047] figure 2 That is, the relationship between the concentration of Sporamin and the percentage of trypsin inhibition. It can be seen from the figure that the Sporamin concentration has different effects on the trypsin inhibitor activity. At 0.1mg / ml, the inhibition rate of Sporamin to trypsin (80μg / ml) can reach 50%; when the concentration of Sporamin is between 0.1-0.3mg / ml, increasing the concentration of Sporamin can significantly inhibit trypsin. Increase; at 0.6mg / ml its inhibition rate can reach 90%. But between 0.6-3mg / ml concentration, the inhibition rate of Sporamin to trypsin did not change significantly.

[0048] Using the exact same experimental conditions as Sp...

Embodiment 3

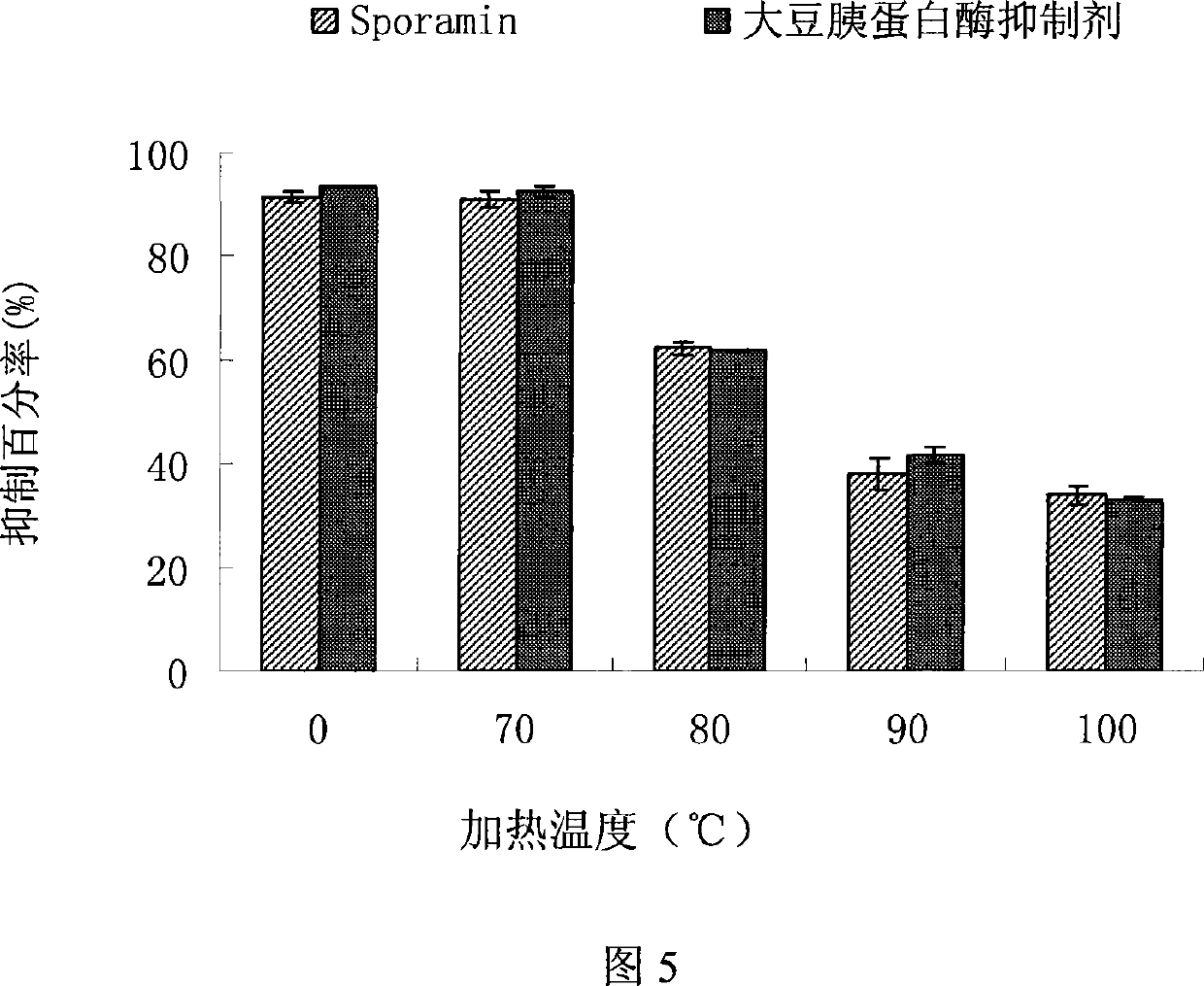

[0049] Example 3. Effect of sterilization pressure on the activity of trypsin inhibitor

[0050] Under the condition of temperature of 25℃, under the pressure of 200MPa, 300MPa, 400MPa, 500MPa and 600MPa, the sweet potato protein Sporamin trypsin inhibitor solution with a concentration of 0.6mg / ml was pressurized for 20min. Inhibitory activity.

[0051] Using the exact same experimental conditions as Sporamin, the activity of soybean trypsin inhibitor was determined.

[0052] image 3 That is, the relationship between the effects of different pressures on the activities of sweet potato protein Sporamin and soybean protein trypsin inhibitor. Depend on image 3 It can be seen that under the pressure condition of 200-600MPa for 20min, there is no significant effect on the trypsin inhibitor activity of Sporamin and soybean.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com