A displacement monitoring system and method

A displacement monitoring and code phase technology, applied in radio wave measurement systems, positioning, measurement devices, etc., can solve the problems of high cost, slow one pass, complex system structure, etc., and achieve low cost, convenient layout and simple system structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

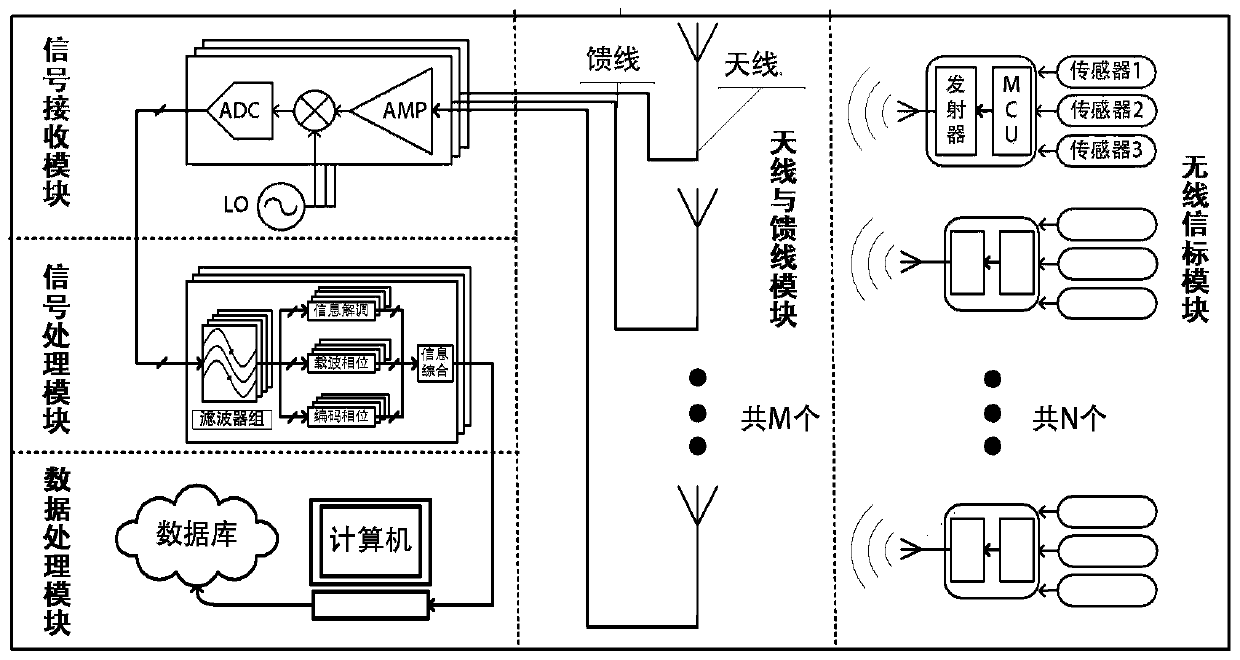

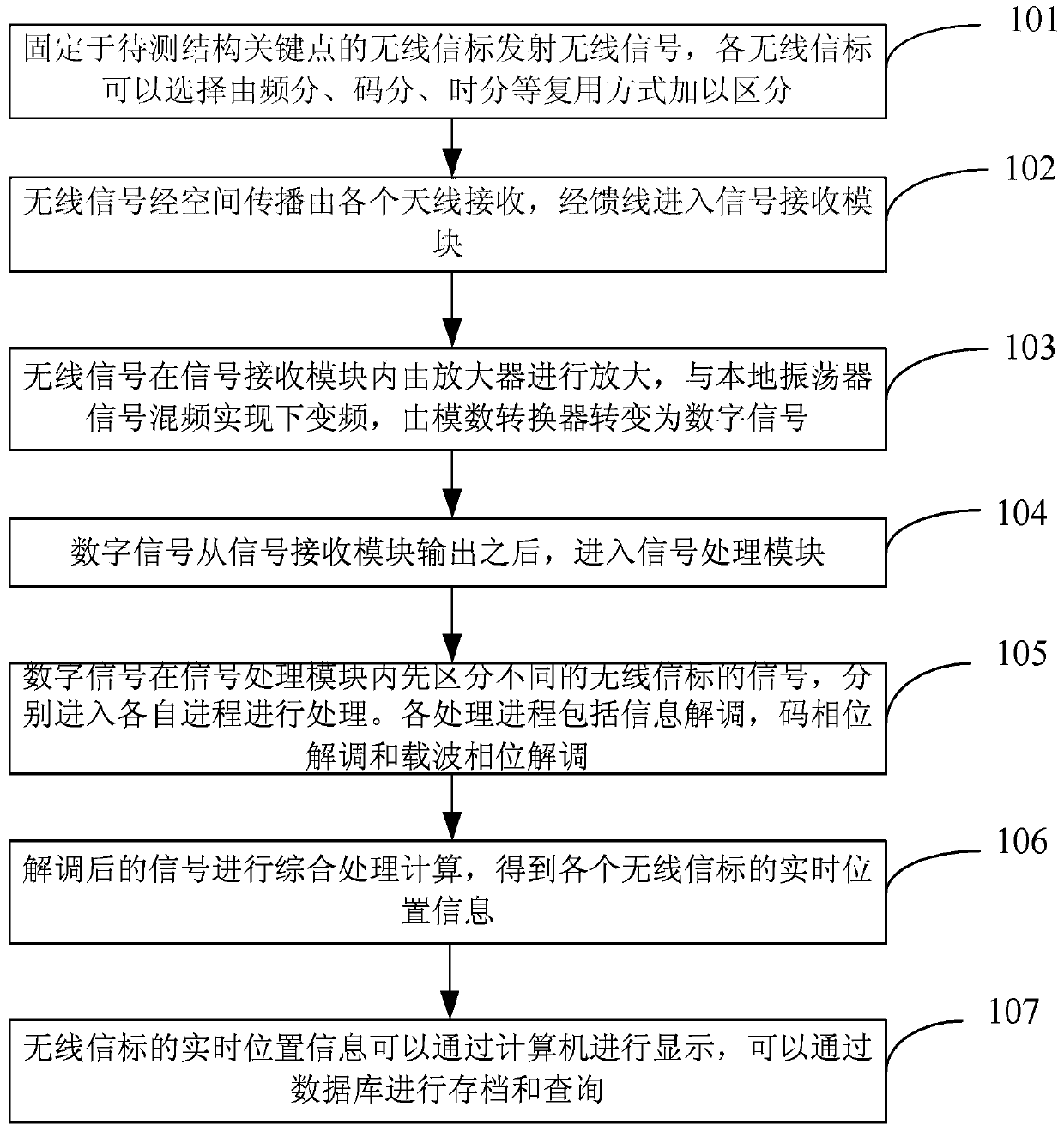

[0054] The wireless beacon module uses Arduino Pro Mini as the encoding controller. The HC-11 wireless serial port module based on the CC1101 RF transceiver chip is responsible for RF signal transmission. The working frequency band is 433MHz and the working distance is about 1000m. Since the B210 has two radio frequency channels, one-dimensional displacement monitoring can be realized.

[0055] The signal receiving module uses Ettus' USRP B210 development board, which includes radio frequency switches, amplifiers, transceivers, FPGAs and USB3.0 interfaces. The antenna adopts 433MHz 3dB gain standard helical antenna. The feeder adopts KSR400 / LMR400 coaxial cable.

[0056] The signal processing module is implemented based on the CPU, the specific hardware is a mobile workstation ThinkPadW520, the software is implemented based on the signal processing program developed by GNURadio, and the software algorithm is as described above.

Embodiment 2

[0058] The hardware of the signal processing module and signal receiving module remains unchanged, and the receiving frequency is set to 2.4GHz through software.

[0059] The wireless beacon uses a wireless module based on nRF24l01+ and works at 2.4GHz.

Embodiment 3

[0061] The signal processing module is implemented based on embedded CPU and FPGA. The specific hardware is Xilinx Zynq-7000 fully programmable SoC ZC706 evaluation board. The core device is Xilinx Zynq-7000, which contains ARM core and FPGA, which can realize high-speed signal processing.

[0062] The signal receiving module uses ADI's AD-FMCOMMS5-EBZ development board, onboard two dual-channel radio frequency transceivers, which can realize the transmission and reception of four radio frequency signals and realize three-dimensional displacement monitoring.

[0063] The wireless beacon can be implemented using example 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com