High-temperature high-pressure hydrolysis-resistant epoxy resin composition for pultrusion as well as preparation method and application thereof

An epoxy resin, high temperature and high pressure technology, applied in the field of epoxy resin, can solve the problem of epoxy resin not resistant to high temperature and high pressure hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

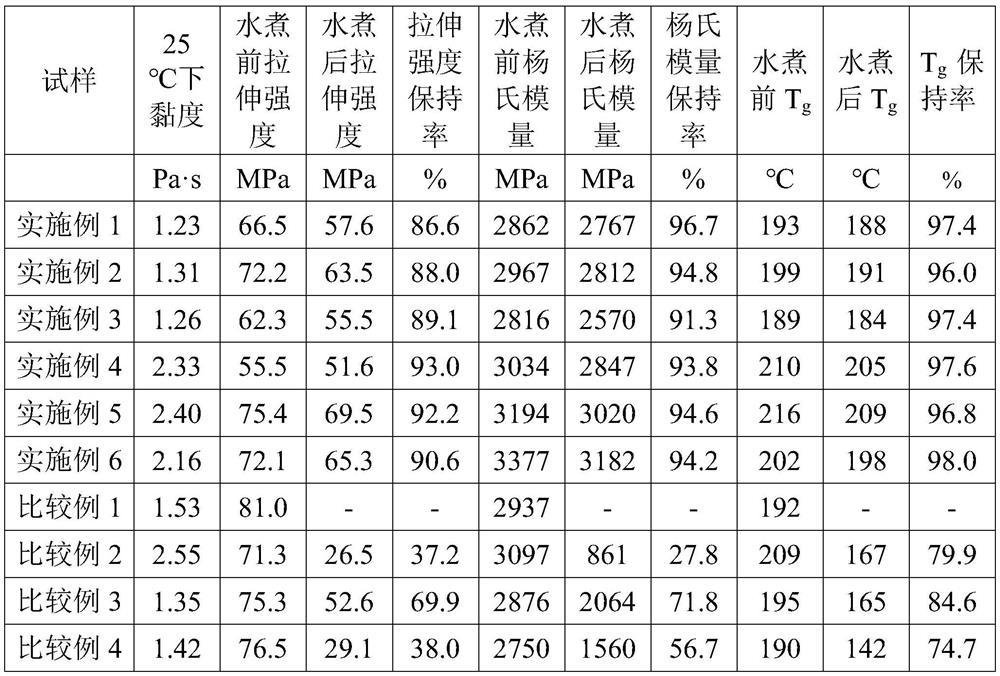

Examples

Embodiment 1

[0031] (1) 100g 4,4'-diaminodiphenylmethane epoxy resin (epoxy value 0.85mol / 100g), 142g methylhexahydrophthalic anhydride, 5g amino-modified silicone oil (number average molecular weight 2000 , amino content 6~7wt%), 5g polyether polyol ep-330n (molecular weight 5000) and 1g triphenylphosphine bromide are added in the there-necked flask, stir while heating up to 70 ℃ under nitrogen protection, make each component Completely miscible. The mixed epoxy resin composition was sampled and tested for viscosity (measured by a Brookfield CAP2000+H series cone-plate viscometer, the rotor type CAP-06, and the rotational speed was 100 rpm).

[0032] (2) Pour the mixed resin into the preheated mold, place the mold in a blast oven, and heat-cure according to the curing process of 100°C / 2h+160°C / 2h. After it cools down to room temperature, remove the resin sample from the mold.

[0033] (3) Test the tensile properties and T of the resin sample before the hydrolysis test g . Test the ten...

Embodiment 2

[0035] (1) 100g 4,4'-diaminodiphenylmethane epoxy resin (epoxy value 0.85mol / 100g), 142g methylhexahydrophthalic anhydride, 5g epoxy modified silicone oil (number average molecular weight 4500, epoxy group content 10~12wt%), 5g polyether polyol ep-330n (molecular weight 5000) and 1g triphenylphosphine bromide join in the there-necked flask, stir while heating up to 70 ℃ under nitrogen protection, make The components are completely miscible. The mixed epoxy resin composition was sampled and tested for viscosity (measured by a Brookfield CAP2000+H series cone-plate viscometer, the rotor type CAP-06, and the rotational speed was 100 rpm).

[0036] (2) Pour the mixed resin into the preheated mold, place the mold in a blast oven, and heat-cure according to the curing process of 100°C / 2h+160°C / 2h. After it cools down to room temperature, remove the resin sample from the mold.

[0037] (3) The test before and after hydrolysis is the same as in Example 1.

Embodiment 3

[0039] (1) 100g 4,4'-diaminodiphenylmethane epoxy resin (epoxy value 0.85mol / 100g), 142g methylhexahydrophthalic anhydride, 5g alcohol hydroxyl modified silicone oil (number average molecular weight 1500, hydroxyl content 8~9wt%), 5g polyether polyol ep-330n (molecular weight 5000) and 1g triphenylphosphine bromide were added in the three-necked flask, and the temperature was raised to 70°C while stirring under the protection of nitrogen, and each group are completely miscible. The mixed epoxy resin composition was sampled and tested for viscosity (measured by a Brookfield CAP2000+H series cone-plate viscometer, the rotor type CAP-06, and the rotational speed was 100 rpm).

[0040] (2) Pour the mixed resin into the preheated mold, place the mold in a blast oven, and heat-cure according to the curing process of 100°C / 2h+160°C / 2h. After it cools down to room temperature, remove the resin sample from the mold.

[0041] (3) The test before and after hydrolysis is the same as in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com