Water-insoluble photopolymerizable composition, material and application

A photopolymerization, non-water-soluble technology, applied in the field of photosensitive materials, can solve the problems of complex synthesis process of photosensitizer, poor compatibility, poor storage stability, etc., achieve good storage stability, widen selection range, water resistance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

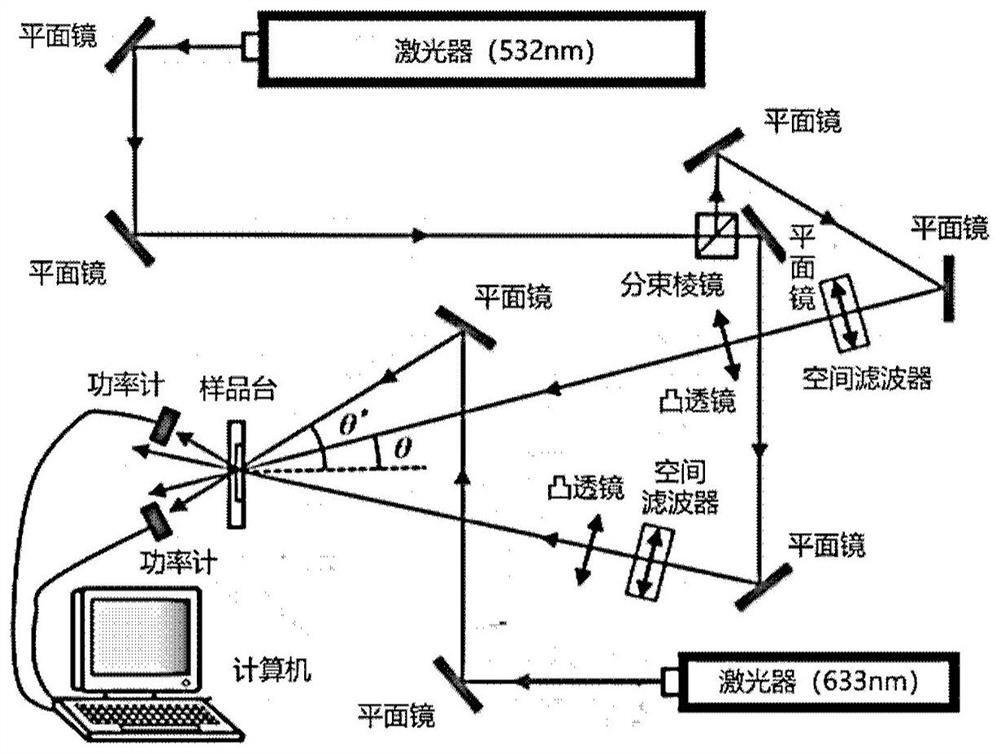

Method used

Image

Examples

Embodiment 1

[0044] Step 1: Prepare a water-insoluble photopolymerizable composition solution

[0045] 20% of film-forming agent polyvinyl acetate, 0.5% of photosensitizer Rose Bengal, 5% of photoinitiator tris(trimethylsilyl)silane, 5% of monomer benzyl methacrylate, dissolved in solvent dimethyl methylene In 69.5% sulfone, it is configured as a water-insoluble photopolymerizable composition solution.

[0046] Step 2: Preparation of water-insoluble photopolymer material

[0047] The solution of the non-water-soluble photopolymerization composition is formed into a film and dried under the condition of 50° C. to prepare a photopolymer holographic material by drip coating under the environment of a red safety light.

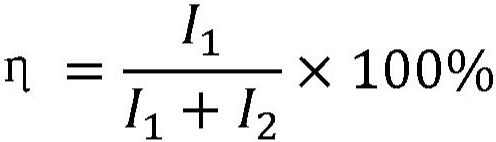

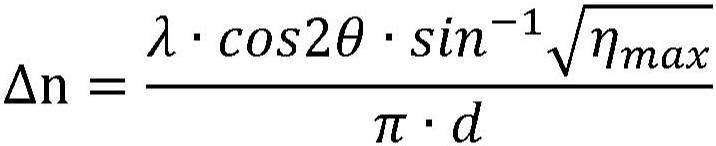

[0048] The performance test results of the obtained photopolymer holographic material: the maximum diffraction efficiency η max =80%, refractive index modulation Δn=1.38×10 -4 , Photosensitivity S=1.49cm / mJ.

Embodiment 2

[0050] Step 1: Prepare a water-insoluble photopolymerizable composition solution

[0051] Film-forming agent polyvinyl acetate 5%, photosensitizer Rose Bengal 0.01%, photoinitiator N-phenylglycine 0.5%, monomer benzyl methacrylate 1%, fluorine surfactant FC-44300.1% Used as a leveling agent, dissolved in 93.39% N, N-dimethylformamide as a solvent, and configured as a water-insoluble photopolymerizable composition solution.

[0052] Step 2: Preparation of water-insoluble photopolymer material

[0053] The solution of the water-insoluble photopolymerization composition is sprayed under the environment of a red safety light, and dried at 30° C. to form a film to prepare a photopolymer holographic material.

[0054] The performance test results of the obtained photopolymer holographic material: the maximum diffraction efficiency η max =82%, refractive index modulation Δn=1.40×10 -4 , Photosensitivity S=1.56cm / mJ.

Embodiment 3

[0056] Step 1: Prepare a water-insoluble photopolymerizable composition solution

[0057] Film-forming agent polymethyl methacrylate 20%, photosensitizer Rose Bengal 1%, photoinitiator 2-(4-methoxyphenyl)-4,6-bis(trichloromethyl)-1,3 , 5-triazine 5%, monomeric benzyl methacrylate 5%, fluorosurfactant FC-44300.1% are used as leveling agent, dissolved in solvent formamide 68.9%, configured as non-water-soluble photoinduced Polymer composition solution.

[0058] Step 2: Preparation of water-insoluble photopolymer material

[0059] The solution of the non-water-soluble photopolymerization composition is formed into a film and dried under the condition of 50° C. to prepare a photopolymer holographic material by drip coating under the environment of a red safety light.

[0060] The performance test results of the obtained photopolymer holographic material: the maximum diffraction efficiency η max =75%, refractive index modulation Δn=1.32×10 -4 , Photosensitivity S=1.92cm / mJ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| photosensitivity | aaaaa | aaaaa |

| photosensitivity | aaaaa | aaaaa |

| photosensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com