Earth-boring bits

A drill bit and roller cone technology, applied in the direction of drill bit, earthwork drilling, drilling equipment, etc., can solve the problems of drill bit corrosion and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the invention relate to bit bodies for forming earth-boring drill bits, roller cones for roller cones, segmented roller cones, cone and tooth composites, and drill bits for making these articles method of the subject. Additionally, the method can be used to make other articles. Certain embodiments of the present drill bit bodies include at least one discontinuous hard phase and a continuous binder phase bonded together with the hard phase. Embodiments of the compositions and methods of the present invention provide increased service life and thereby improved The useful life of an earth-boring drill bit or other tool. The body material of the bit body, roller cone, insert roller cone, cone provides an integral character to each area of the article.

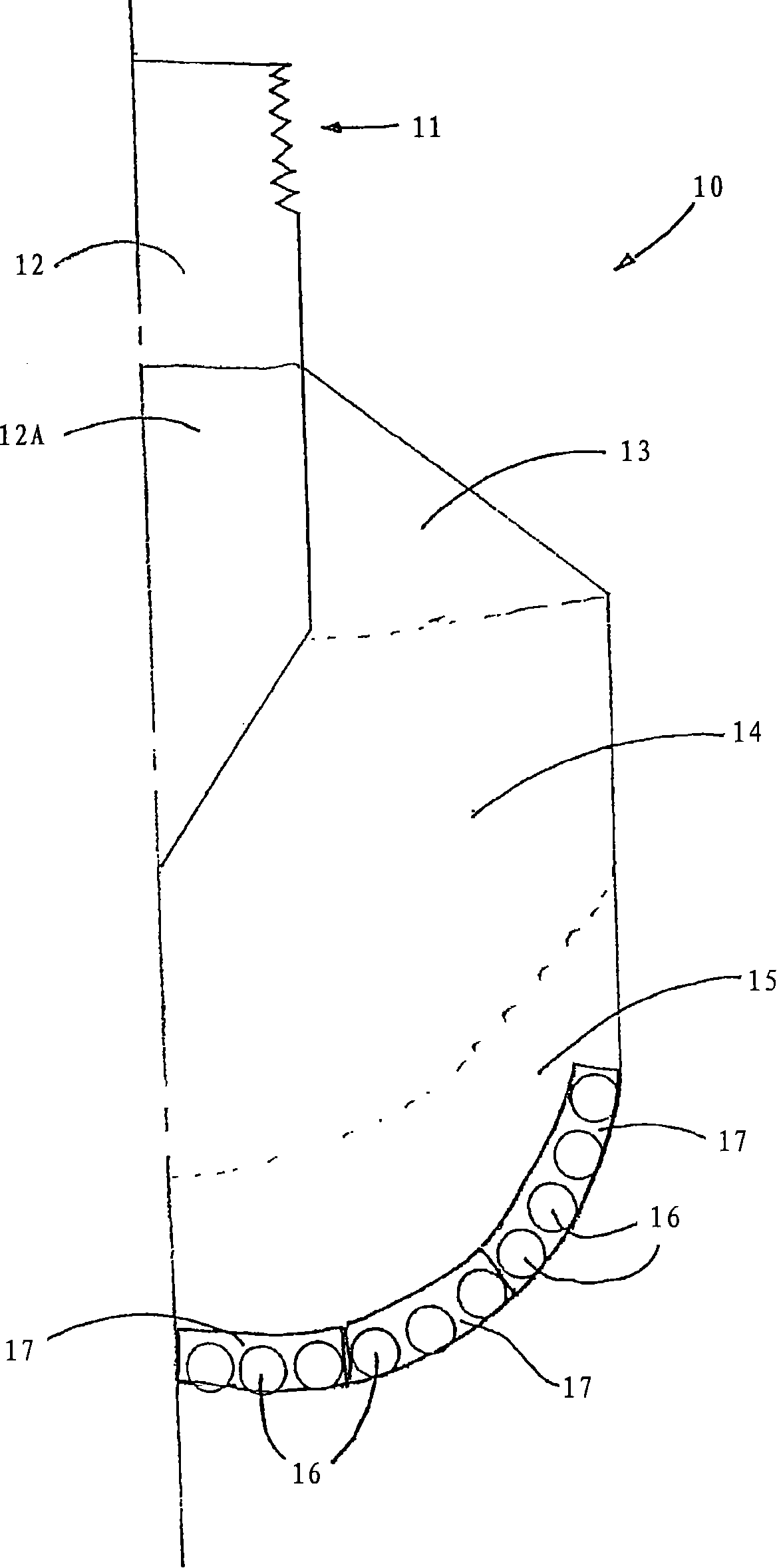

[0040] figure 1 A typical drill bit body 10 is shown for earth boring with fixed cutters. In general, the drill body 10 includes an attachment means 11 on the shank 12 and a blank area 12A incorporated ...

PUM

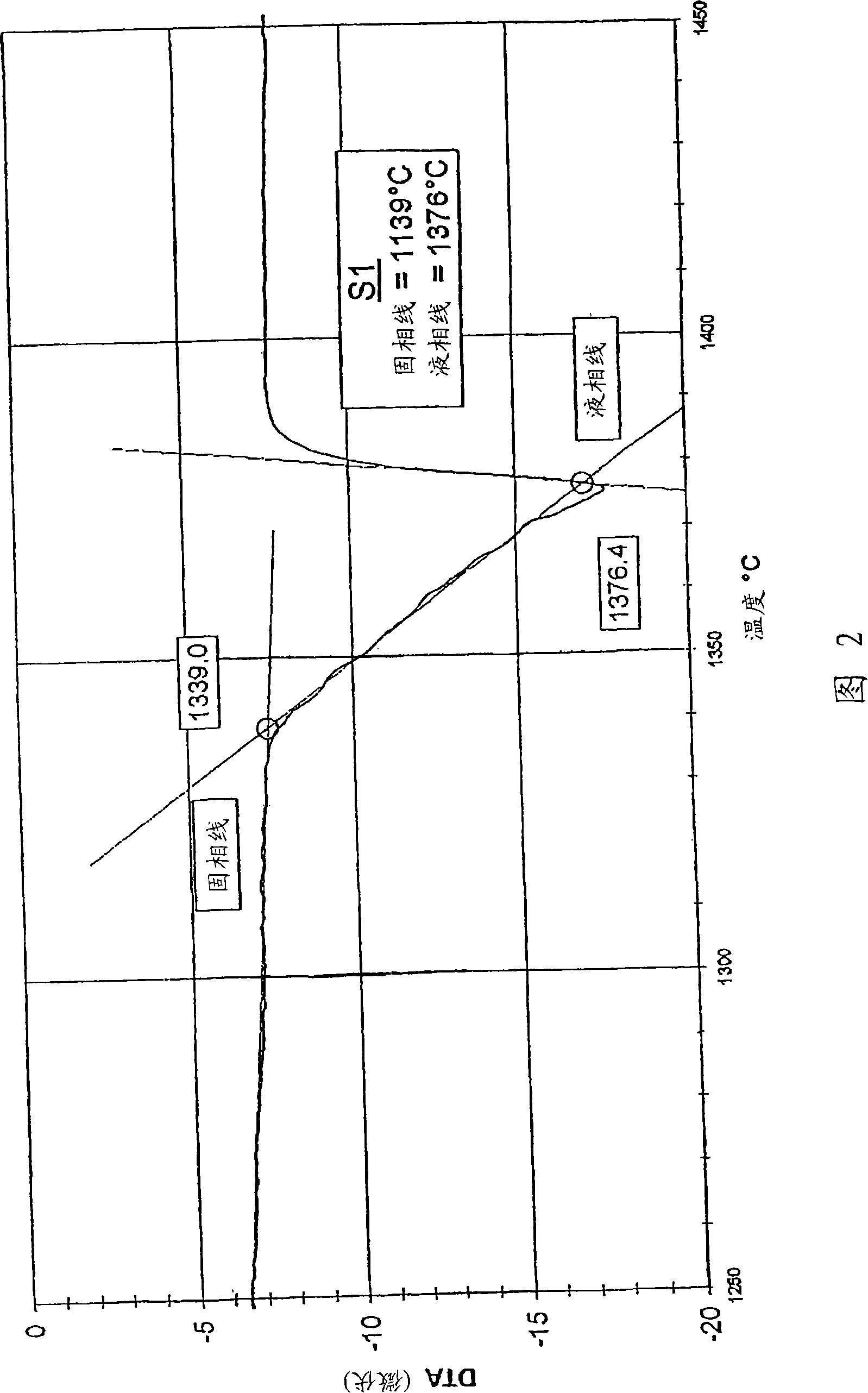

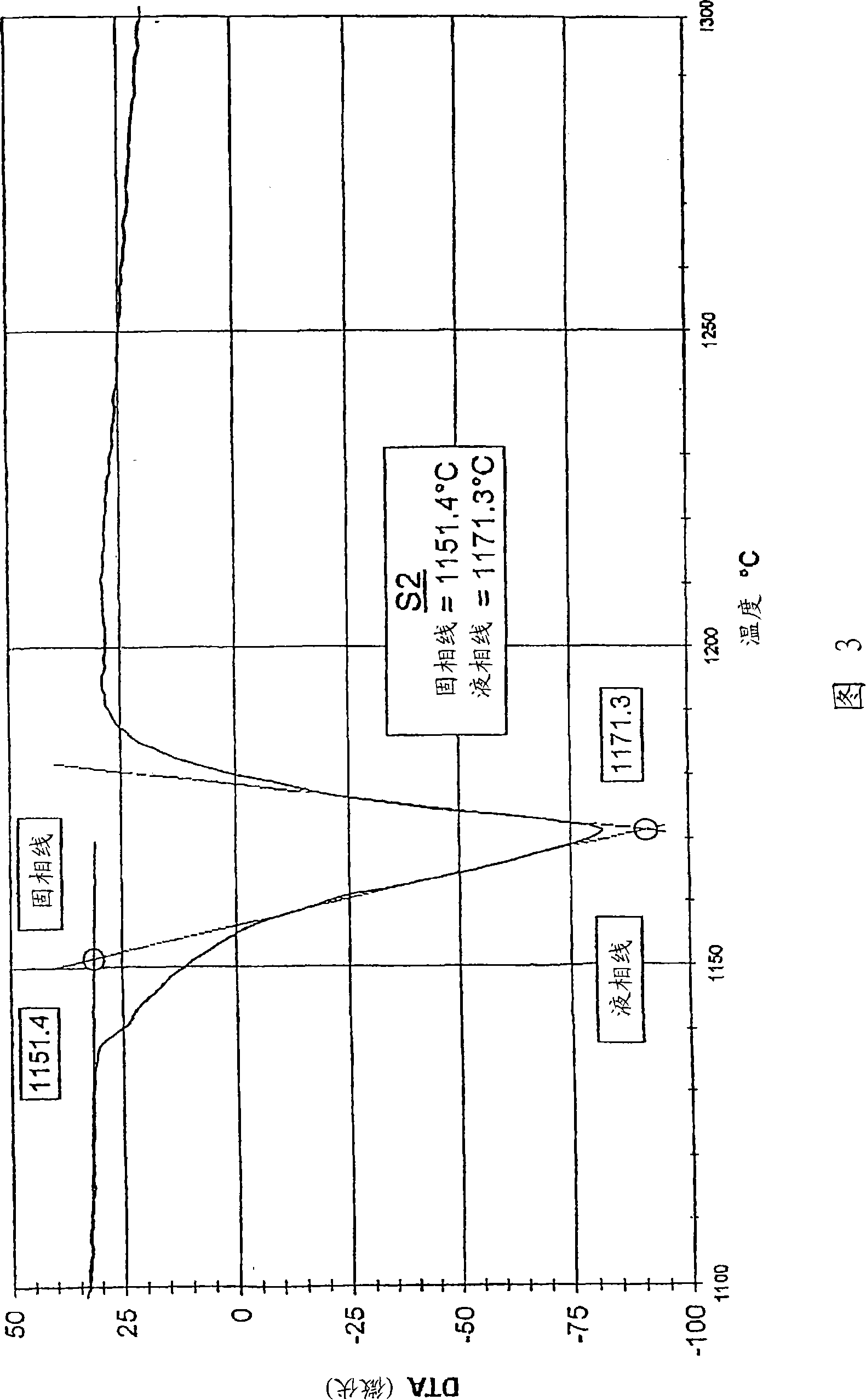

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com