Polarizing plate and display device

A technology for display devices and polarizers, applied in optics, optical elements, polarizing elements, etc., which can solve problems such as easy mixing of air bubbles, difficulty in reducing the weight of polarizers, and deviation of bonding positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0386] Production of Polarizer Protective Film A

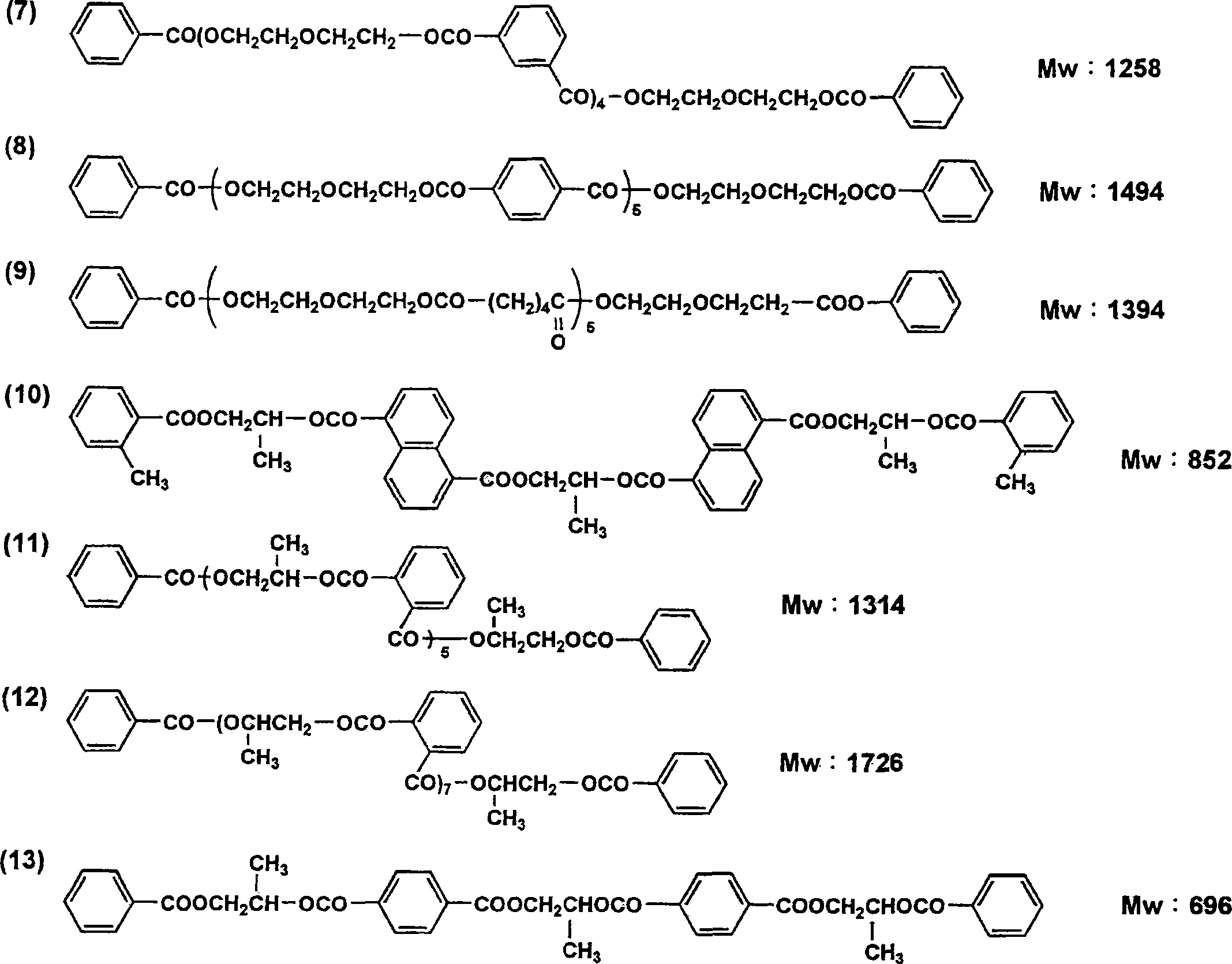

[0387] The used plasticizers and UV absorbers are shown in Table 1.

[0388] In Table 1, UV absorber 1 can be synthesized by the following synthesis recipe.

[0389]

[0390] 2(2'-hydroxy-5'-tert-butyl-phenyl)-5-(2'-methacryloyloxy)ethoxycarbonyl-2H-benzotriazole (exemplary compound MUV-19), according to synthesized by the method described below.

[0391]20.0 g of 3-nitro-4-amino-benzoic acid was dissolved in 160 ml of water, and 43 ml of concentrated hydrochloric acid was added. After adding 20 ml of 8.0 g of sodium nitrite dissolved in water at 0°C, it was stirred at 0°C for 2 hours. This solution was added dropwise at 0°C while dissolving 17.3 g of 4-tert-butylphenol in 50 ml of water and 100 ml of ethanol, while keeping the liquidity alkaline with potassium carbonate. The solution was kept at 0°C for 1 hour, and then stirred at room temperature for 1 hour. The reaction solution was made acidic with hydrochloric acid...

Embodiment 2

[0493] (Production of optical film with anti-reflection layer)

[0494] Using the cellulose ester film 301 produced above as the polarizer protective film A, an optical film with an antireflection layer was produced in the following procedure.

[0495] The refractive index of each layer constituting the antireflection layer was measured by the following method.

[0496] (refractive index)

[0497] The refractive index of each refractive index layer was calculated|required from the measurement result of the spectral reflectance with a spectrophotometer with respect to the sample which coated each layer individually on the hard coat film produced below. The spectrophotometer uses U-4000 type (manufactured by Hitachi, Ltd.). After the inner surface of the sample measurement side is roughened, it is treated with black spray to prevent light reflection on the inner surface. The measurement of the reflectance in the visible light region (400nm ~ 700nm) is carried out under the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com