Method for preparing yttrium iron garnet ferrite material

A ferrite material, yttrium iron garnet technology, applied in the field of preparation of microwave ferrite materials, can solve the problems of time-consuming and energy consumption, and achieve the effect of low magnetoelectric loss and excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

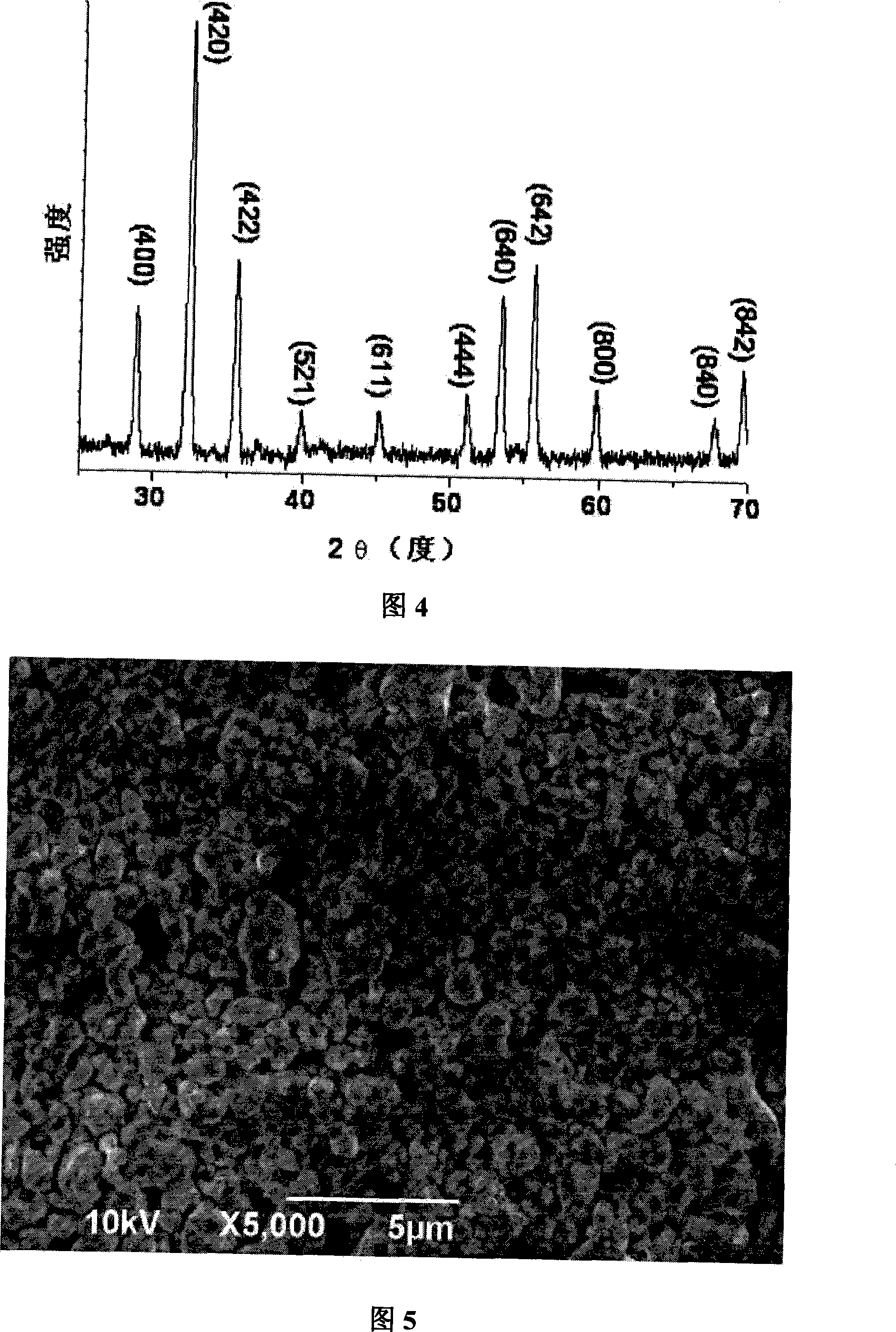

[0030] The microwave sintered yttrium-iron-garnet ferromagnetic ferrite material proposed by the present invention has its process equipment as shown in Figure 2. The NL75 microwave sintering furnace is used to crystallize the material. The device includes an infrared temperature measuring hole 1 and a quartz crucible 2 with a cover. , material to be fired 3, silicon carbide powder 4, corundum crucible 5, microwave oven outer cavity 6, refractory brick 7.

[0031] A microwave sintered yttrium iron garnet microwave ferrite material provided by the present invention is mainly made by the following five steps:

[0032] Step 1: Ingredients

[0033] Use analytically pure Fe with a purity of 99.99% 2 o 3 and analytically pure Y with a purity of 99.99% 2 o 3 As a raw material, according to the chemical formula of pure yttrium iron garnet (Y 3 Fe 5 o 12 ) to calculate the required ratio of raw materials.

[0034] For example: the required yttrium iron garnet ferrite material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com