Self-emulsifying microemulsion daidzein oral liquid preparation composite and preparation method thereof

A technology of daidzein and oral preparations, which is applied in the directions of drug combination, medical preparations containing active ingredients, and pharmaceutical formulas, can solve the problems of coking, melting, and inability to carry out production, and achieves low viscosity, easy storage, and bioavailability. The effect of increasing the degree of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The components and weight percentages of the self-microemulsifying composition in this embodiment are: 1% daidzein, 60% emulsifier, 20% co-emulsifier, and 19% oil.

[0024] Described emulsifier is polyoxyethylene hydrogenated castor oil.

[0025] Described co-emulsifier is polyethylene glycol 400.

[0026] Described grease is ethyl oleate.

[0027] The preparation process of the self-microemulsifying composition in this example is as follows: at 10-80°C, first dissolve daidzein in the prescribed amount of polyethylene glycol 400, and after cooling, add polyoxygen according to the prescribed amount. Ethylene hydrogenated castor oil and ethyl oleate, just stir well.

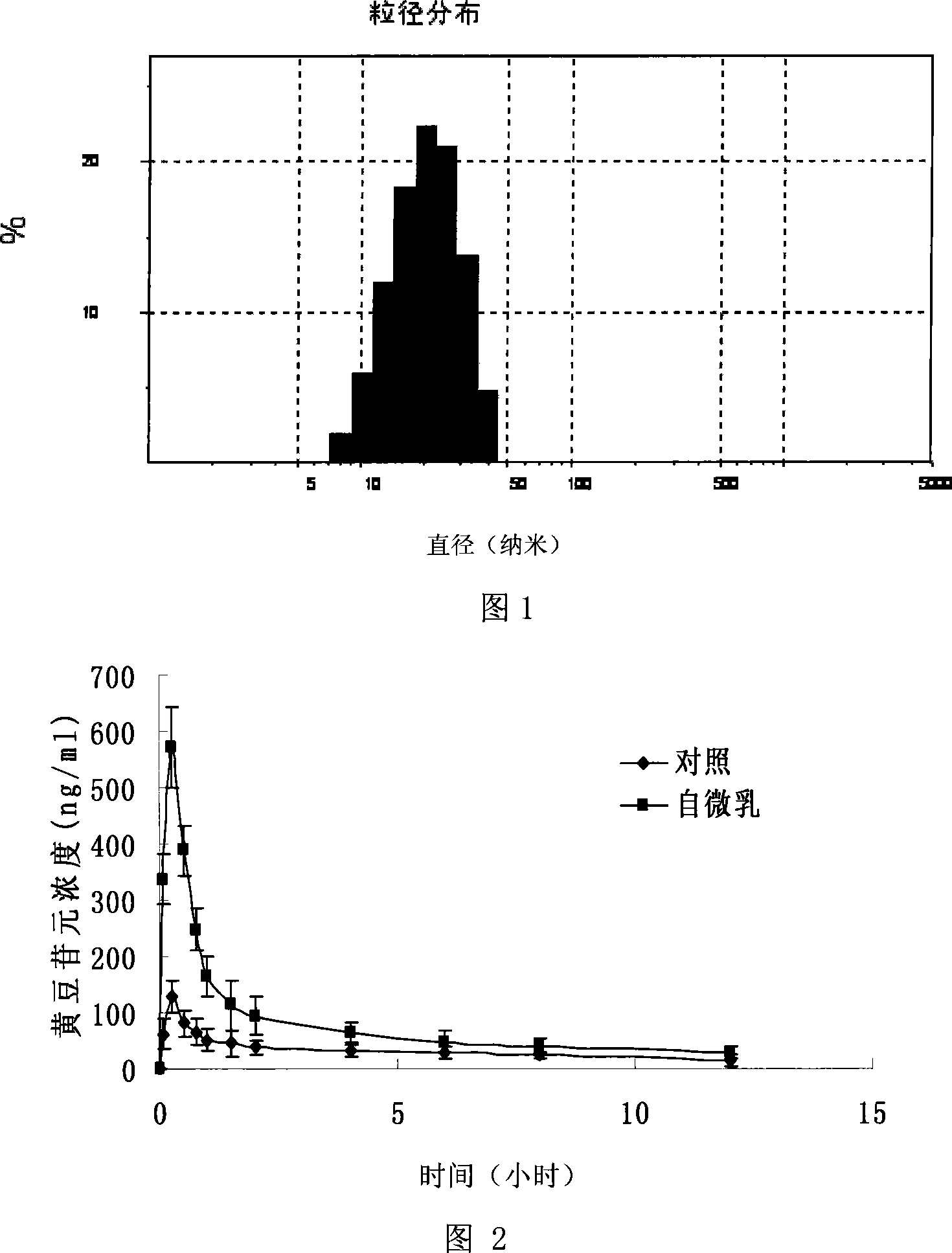

[0028] The beneficial effects of this embodiment are: (1) After preparing the drug into a self-microemulsifying composition, using 0.1M HCl as the dissolution medium, more than 80% of daidzein can be dissolved from the self-microemulsifying composition in 30 minutes. (2) After diluting the prepared self-m...

Embodiment 2

[0030] The components and weight percentages of the self-microemulsifying composition in this embodiment are: 0.5% daidzein, 55% emulsifier, 24.5% co-emulsifier, and 10% oil.

[0031] Described emulsifier is polyoxyethylene castor oil.

[0032] Described co-emulsifier is polyethylene glycol 400.

[0033] Described grease is isopropyl myristate.

[0034] The preparation process of the self-microemulsifying composition in this example is as follows: at 10-80°C, first dissolve daidzein in the prescribed amount of polyethylene glycol 400, and after cooling, add polyoxygen according to the prescribed amount. Ethylene castor oil and isopropyl myristate, stir well.

[0035] The beneficial effects of this embodiment are: (1) After preparing the drug into a self-microemulsifying composition, using 0.1M HCl as the dissolution medium, more than 80% of daidzein can be dissolved from the self-microemulsifying composition in 30 minutes. (2) After diluting the prepared self-microemulsifie...

Embodiment 3

[0037] The components and weight percentages of the self-microemulsifying composition in this embodiment are: 0.5% daidzein, 60% emulsifier, 20% co-emulsifier, and 19.5% oil.

[0038] Described emulsifier is polyoxyethylene castor oil.

[0039] Described co-emulsifier is propylene glycol.

[0040] Described grease is isopropyl myristate.

[0041] The preparation process of the self-microemulsifying composition in this example is as follows: at a temperature of 10-80°C, first dissolve daidzein in the prescribed amount of propylene glycol, and after cooling, add polyoxyethylene castor oil and Isopropyl myristate, stir evenly.

[0042] The beneficial effects of this embodiment are: (1) After preparing the drug into a self-microemulsifying composition, using 0.1M HCl as the dissolution medium, more than 80% of daidzein can be dissolved from the self-microemulsifying composition in 30 minutes. (2) After diluting the prepared self-microemulsified composition 100 times, the partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com