Hot flue gas bidirectional firing, high anthrax adaptability and variable load honeycomb type coal boiler

A hot flue gas and adaptive technology, applied in the boiler field, can solve the problems of boiler manufacturing cost and boiler floor area increase, inflexible load adjustment of briquette boilers, and difficulty in large-scale briquette boilers, etc., to achieve effective grate Area saving, saving equipment investment and floor area, wide adaptability of coal quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

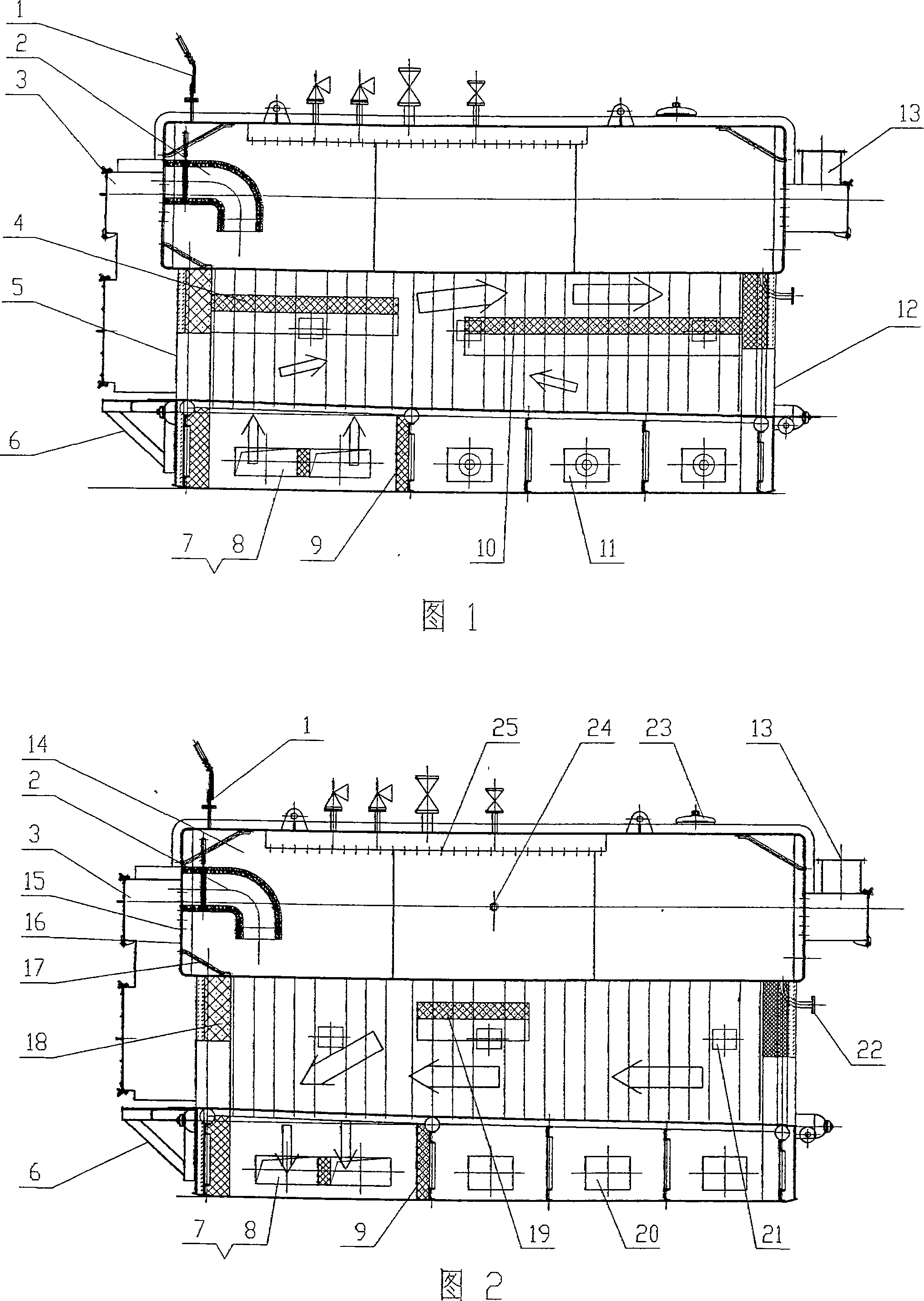

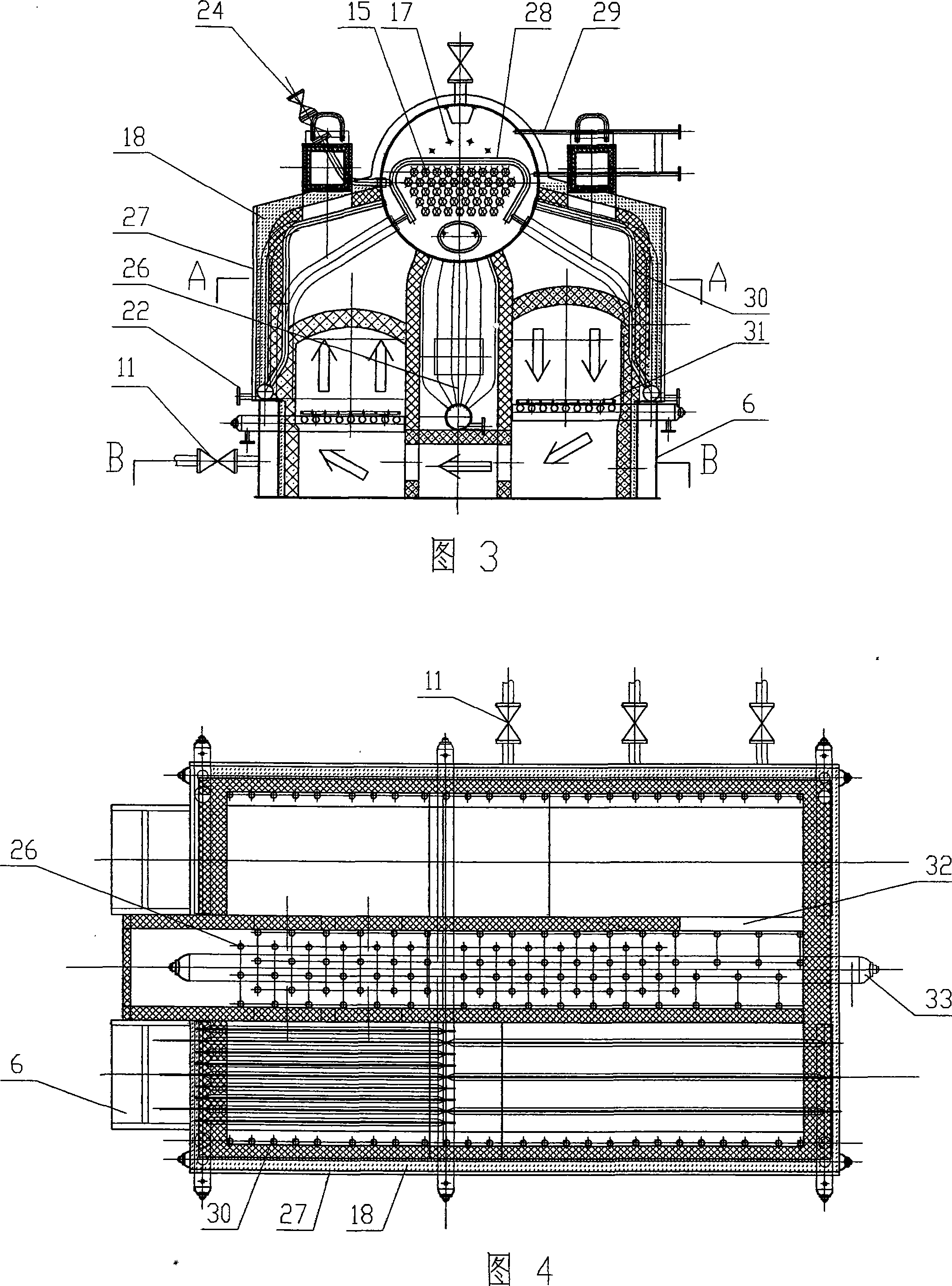

Embodiment 1

[0033] When used for steam boilers, it includes: bottom seat 6; connected to bottom seat 6 are front furnace door 5, rear furnace door 12, furnace wall 18, smoke partition wall 9 under the water-cooled grate, and horizontal smoke partition at the lower part of the convection header Wall 54, left air chamber flow-adjustable air inlet door 11, right air chamber air inlet door 20; the steam boiler is placed along the air-tight drainage grate pipe 39 to connect the steam boiler water-cooled grate front horizontal header 36 and the steam boiler water-cooled grate The central horizontal header 35 is connected together; the gas boiler is placed in parallel with the thin water cooling grate pipe 44 to connect the steam boiler water-cooled grate middle horizontal header 35 and the steam boiler water-cooled grate rear horizontal header 34 together; the right steam boiler There is a smoke outlet door 8 at the lower part of the right side dense drain cooling grate pipe 39; The smoke door ...

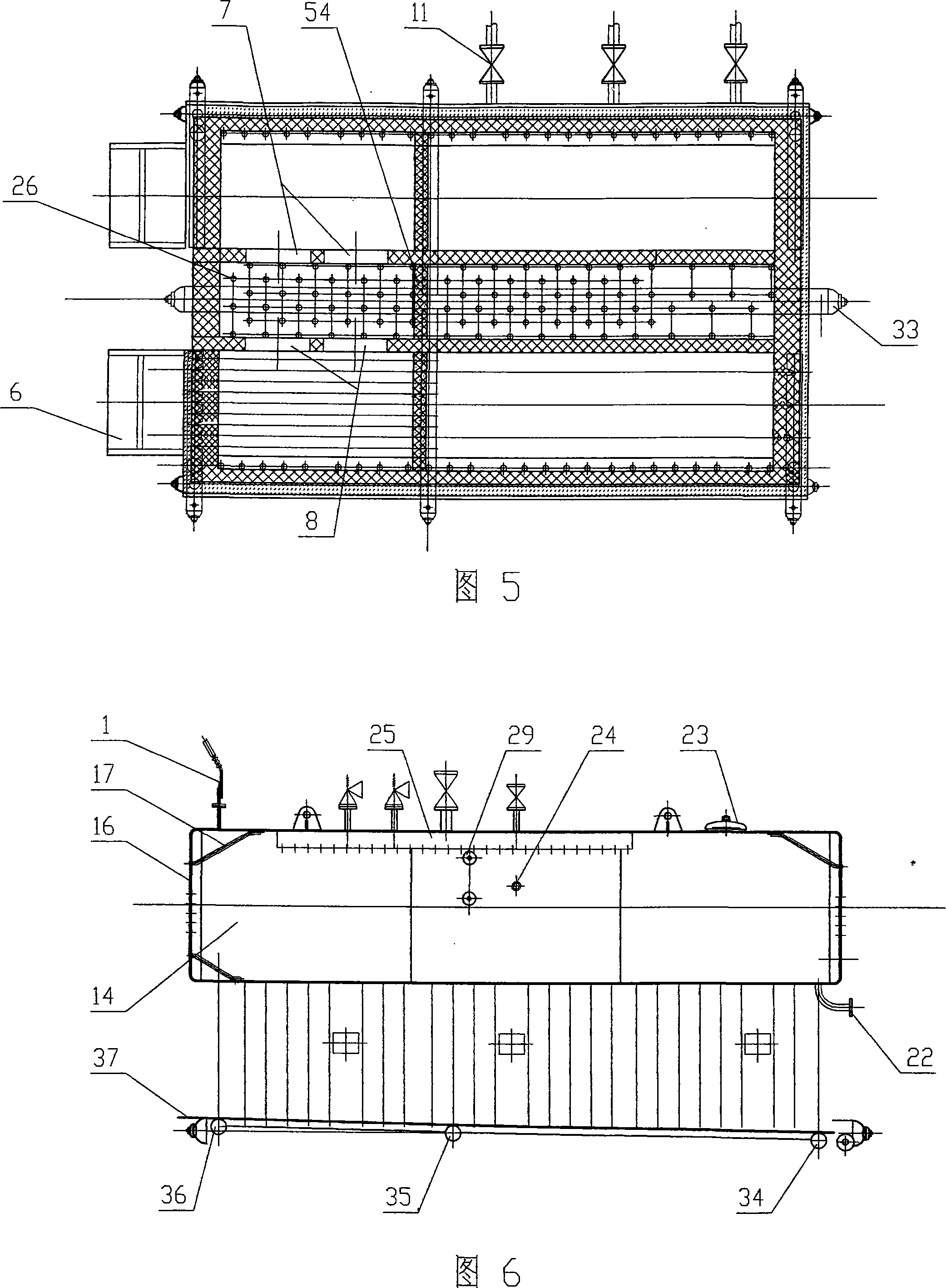

Embodiment 2

[0038] When used for hot water boilers, it includes: bottom seat 6; connected with bottom seat 6 are front furnace door 5, rear furnace door 12, furnace wall 18, smoke partition wall 9 under water-cooled grate, horizontal partition at the lower part of convection header The smoke wall 54, the flow-adjustable air inlet door 11 of the left air chamber, and the air inlet door 20 of the right air chamber; The horizontal header 47 in the row is connected together; the horizontal header 47 of the water furnace water-cooled grate and the rear horizontal header 48 of the water furnace water-cooled grate are connected together by the water boiler with the thin water cooling grate pipe 53; The furnace is placed in parallel with the dense drain cooling furnace grate pipe 51, and the right side dense drain cooling furnace grate is equipped with a smoke outlet door 8; The smoke inlet door 7; the right furnace is provided with the right furnace arch 19; the left furnace is provided with the...

Embodiment 3

[0044] The left hearth is provided with a left hearth arch 19; the right hearth is provided with a right hearth front arch 4 and a right hearth rear arch 10; the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com