Method for preparing fishbone-shaped nano carbon fibre for filling nano metal

A nano-carbon fiber and nano-metal technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and paper making, etc., can solve the problems of difficult preparation, control and high price of small-diameter catalysts, and achieves the advantages of large-scale production and wide application. Prospects, the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

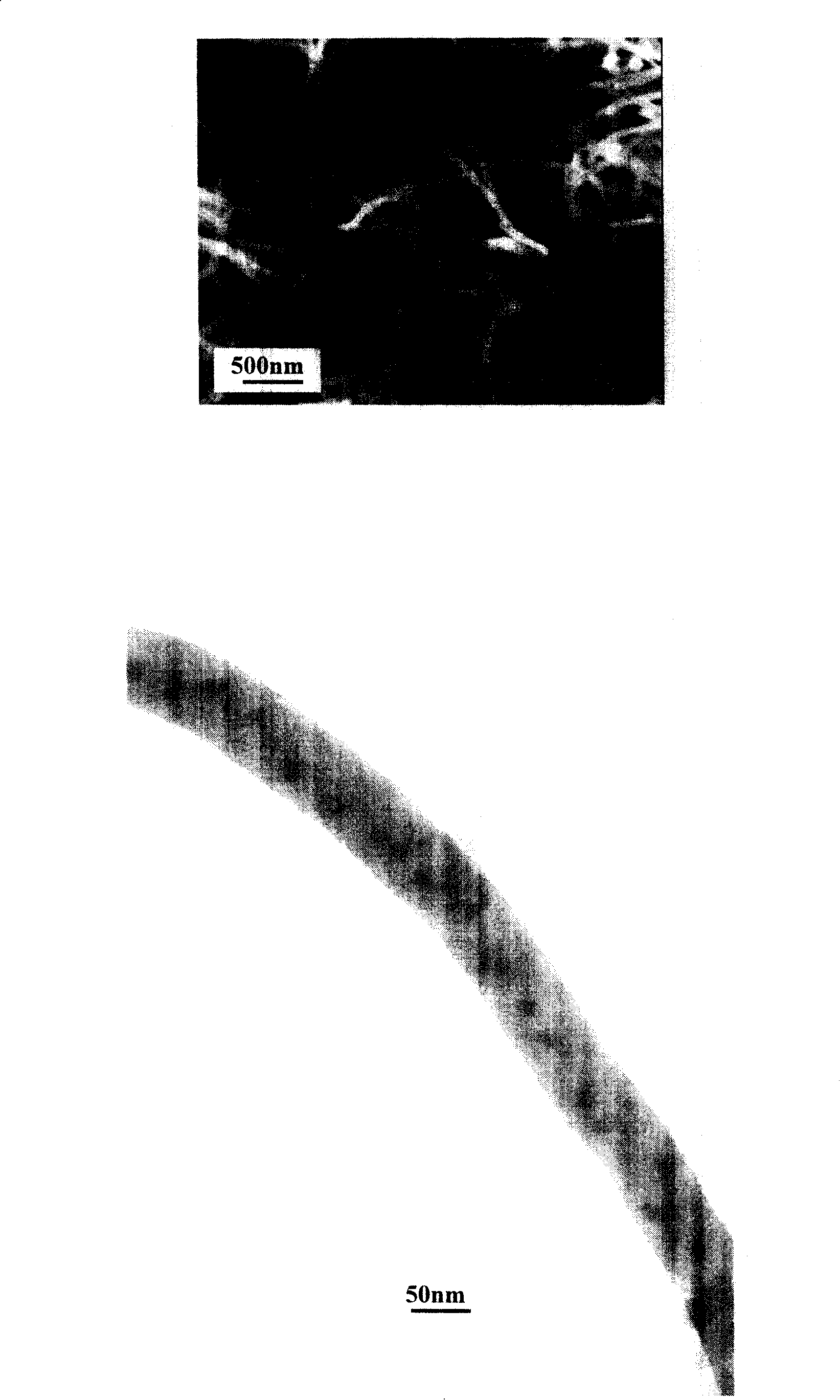

Image

Examples

Embodiment 1

[0013] Before the reaction, the nickel plate catalyst with a thickness of 1mm and a length and width of 200mm and 25mm was subjected to surface treatment, and the surface of the nickel plate was polished with No. 500 fine sandpaper, then soaked in dilute sulfuric acid for 5 hours, dried and placed in a tube furnace In the constant temperature zone, the nickel plate catalyst is placed horizontally on the graphite plate; the reaction system is evacuated, replaced with nitrogen three times, and nitrogen is introduced. The flow rate of nitrogen is 250ml / min. At the same time, hydrogen is used as the carrier gas to add thiophene co-catalyst, the flow rate of thiophene co-catalyst is 0.05ml / min, the ratio of diluent gas nitrogen and acetylene flow is 5:1 (wherein: acetylene is 50ml / min, nitrogen is 250ml / min), The ratio of hydrogen and acetylene flow rate is 6: 1 (wherein: acetylene is 50ml / min, hydrogen is 300ml / min), reaction constant temperature time is 60min, carries out catalyti...

Embodiment 2

[0015] Before the reaction, the nickel plate catalyst with a thickness of 1.5mm and a length and width of 200mm and 25mm was surface treated, and the surface of the nickel plate was polished with No. 500 fine sandpaper, then soaked in dilute sulfuric acid for 6 hours, dried and placed in a tubular In the constant temperature zone of the furnace, the nickel plate catalyst is placed horizontally on the graphite plate; the reaction system is evacuated, replaced with argon three times, and argon is introduced. The flow rate of argon is 360ml / min, and the temperature is raised to 800°C under an argon atmosphere. , while passing through acetylene, add thiophene co-catalyst with hydrogen as carrier gas, the flow rate of thiophene co-catalyst is 0.06ml / min, the ratio of dilution gas argon and acetylene flow is 6: 1 (wherein: acetylene is 60ml / min, argon Gas is 360ml / min), the ratio of hydrogen and acetylene flow rate is 7: 1 (wherein: acetylene is 60ml / min, and hydrogen is 420ml / min), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com