LED and its making method

A technology of light-emitting diodes and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve problems such as high process difficulty and low yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

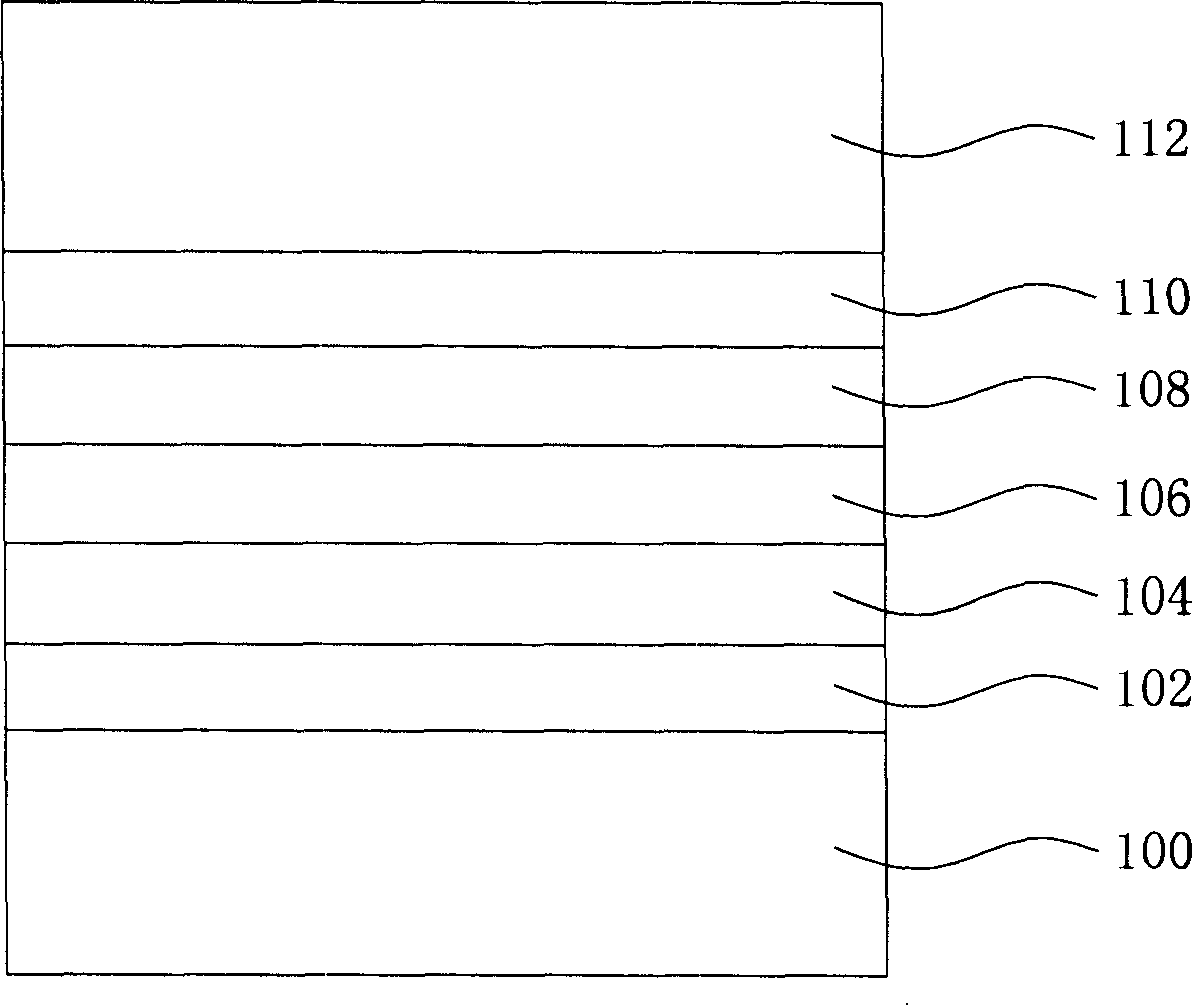

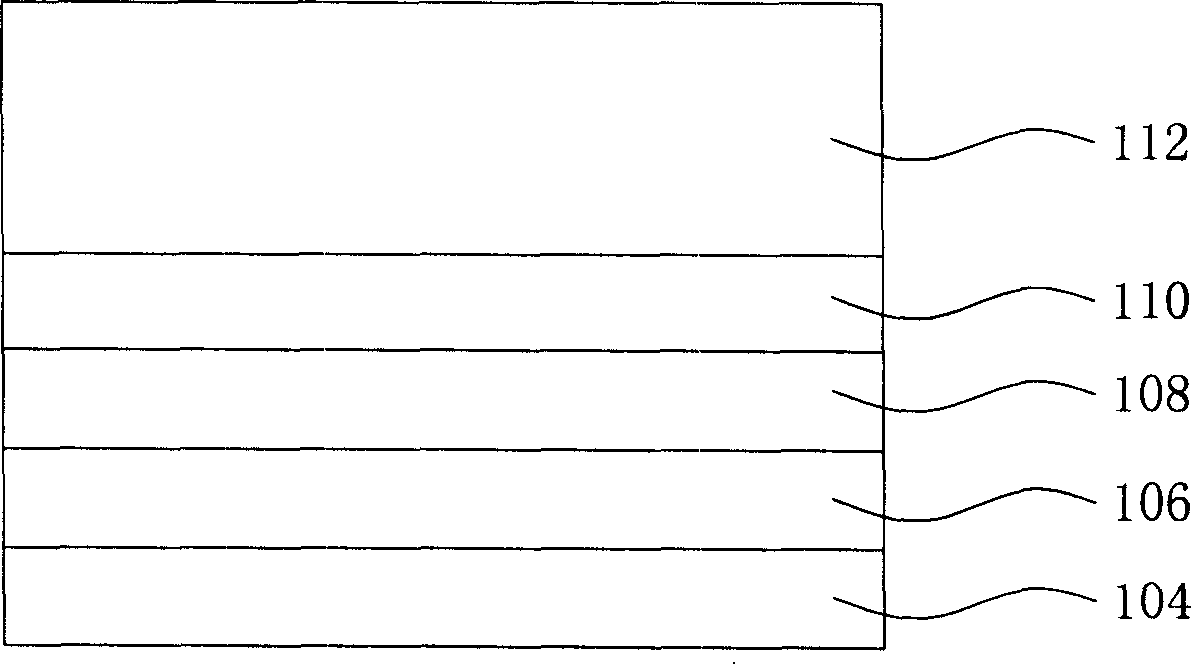

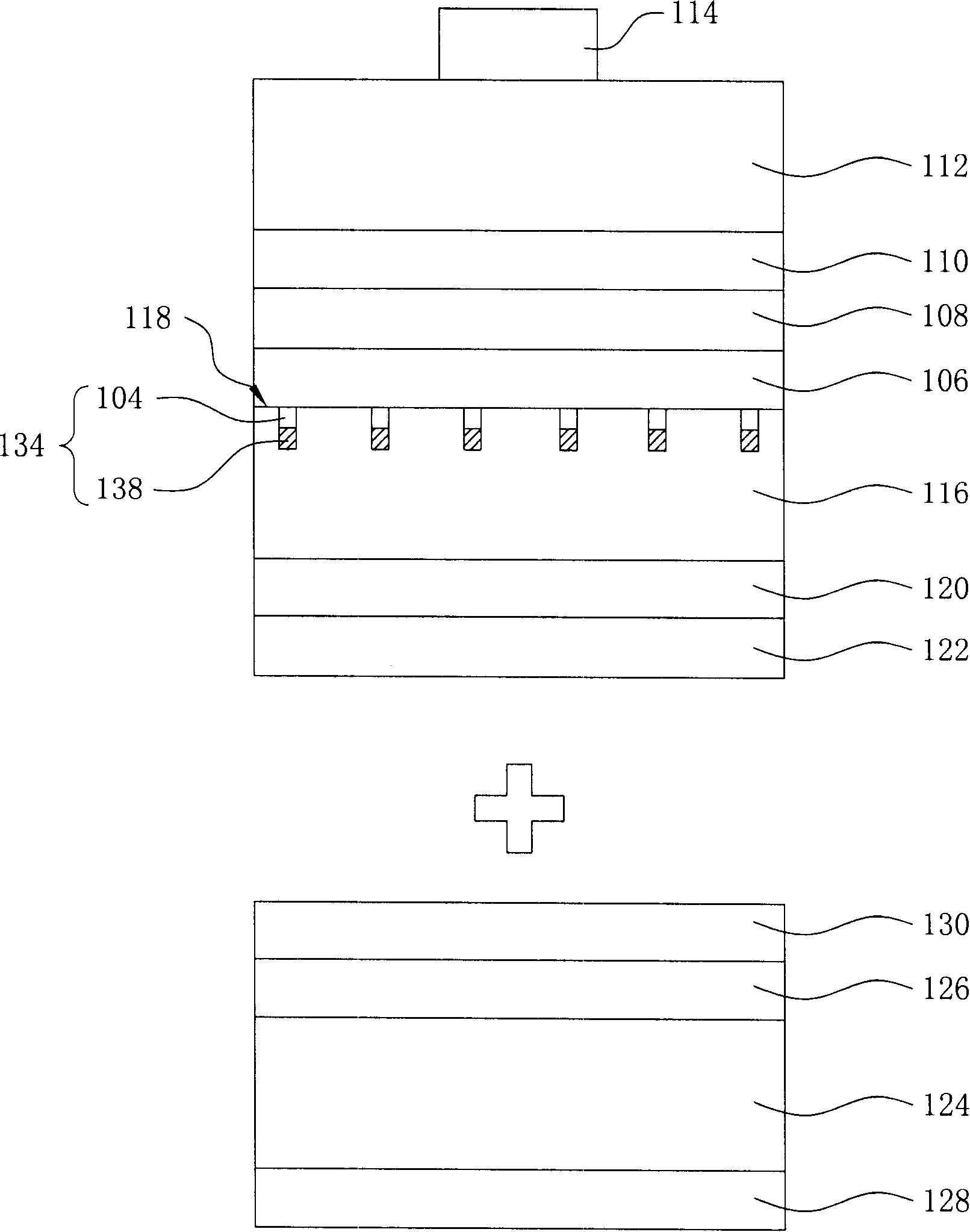

[0014] The invention discloses a light-emitting diode and its manufacturing method, which has a thicker window layer, so that the current diffusion can be enhanced, and the light extraction efficiency can be improved, which is more conducive to the roughening treatment of the surface of the element, and further improves the light extraction rate to achieve an improvement. Efficacy of the luminance of light-emitting diode components. In addition, all necessary processes can be completed before wafer bonding, so the bonding temperature is more flexible, and a wider process window can be obtained. Furthermore, an alloy with a lower melting point can be used as the die bonding medium, thereby improving the reliability of the die bonding process. In order to make the narration of the present invention more detailed and complete, you can refer to the following combination Figure 1 to Figure 4 description of.

[0015] Please refer to Figure 1 to Figure 4 , which is a sectional vie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com