Method for producing bismuth trifluoride anode material of Li secondary battery

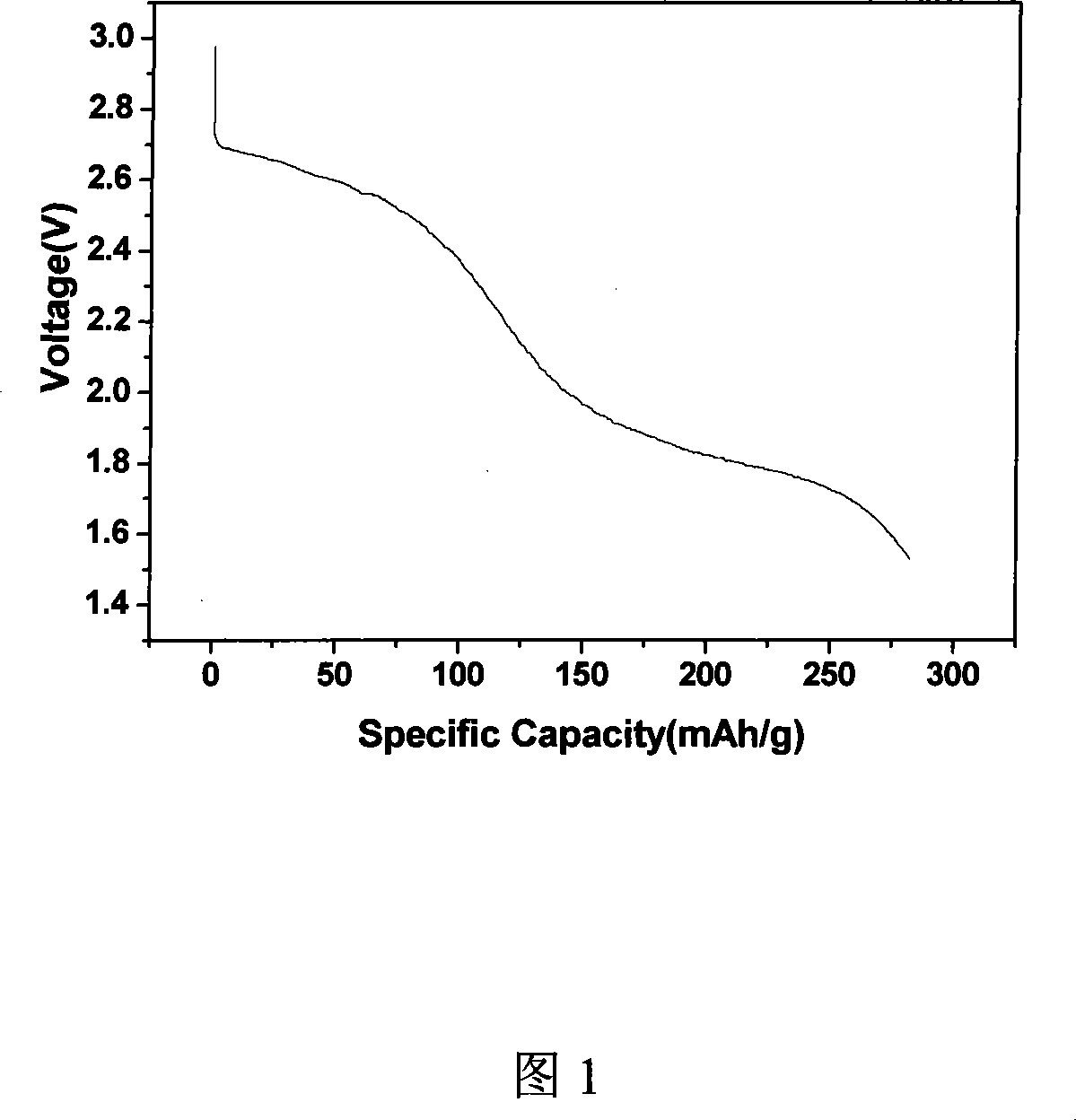

A lithium secondary battery and positive electrode material technology, applied in the direction of fluoride preparation, electrode manufacturing, battery electrodes, etc., can solve the problems of expensive products, complicated impurity removal process, and many impurities, and achieve regular particle crystallization and good discharge performance , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 6 grams of bismuth subnitrate in 400 mL of 20% acetic acid solution and stir at 25 ° C for 2 hours to dissolve the bismuth salt acetic acid solution; gram to obtain a mixed solution of bismuth salt; 2.1 grams of NH 4 F was dissolved in 100 mL of 20% aqueous ethanol, and NH 4 F solution was added dropwise to 3°C bismuth subnitrate solution to obtain BiF 3 Precipitate, the BiF 3 The precipitate was filtered with suction, washed with deionized water, and then dried in a vacuum oven at 70°C for 24 hours to obtain BiF 3 product,.

Embodiment 2

[0025] Weigh 10 grams of bismuth sulfate and dissolve it in 300 mL of 25% acetic acid solution at 45°C for 5 hours to obtain bismuth salt acetic acid solution; add 100 mL of dispersant ethanol and 0.5 g of OP emulsifier to the bismuth salt acetic acid solution to obtain bismuth salt Salt mixed solution; 4 g NH 4 Dissolve F in 100mL 30% ethanol aqueous solution to obtain a mixed solution of alcohol and fluorine; add the mixed solution of alcohol and fluorine dropwise to 10°C bismuth sulfate solution to obtain BiF 3 Precipitate, the BiF 3 The precipitate was filtered with suction, washed with deionized water, and then dried in a vacuum oven at 80°C for 12 hours to obtain BiF 3 product.

Embodiment 3

[0027] Weigh 15 grams of bismuth tartrate and dissolve it in 200 mL of 35% acetic acid solution at 35°C for 3 hours to obtain bismuth salt acetic acid solution; add 100 mL of dispersant ethanol and 1 gram of OP emulsifier to the bismuth salt acetic acid solution to obtain bismuth Salt mixed solution; 3.5 g of NH 4 Dissolve F in 250mL of 15% aqueous ethanol to obtain a mixed solution of alcohol and fluorine; add the mixed solution of alcohol and fluorine dropwise to 5°C bismuth tartrate solution to obtain BiF 3 Precipitate, the BiF 3 The precipitate was filtered with suction, washed with deionized water, and then dried in a vacuum oven at 60°C for 18 hours to obtain BiF 3 product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com