Method of welding foamed aluminium and alloy

A welding method and foamed aluminum technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as low material strength, unformable weld seam, difficulty in welding foamed aluminum, etc., achieve uniform heating, small deformation, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

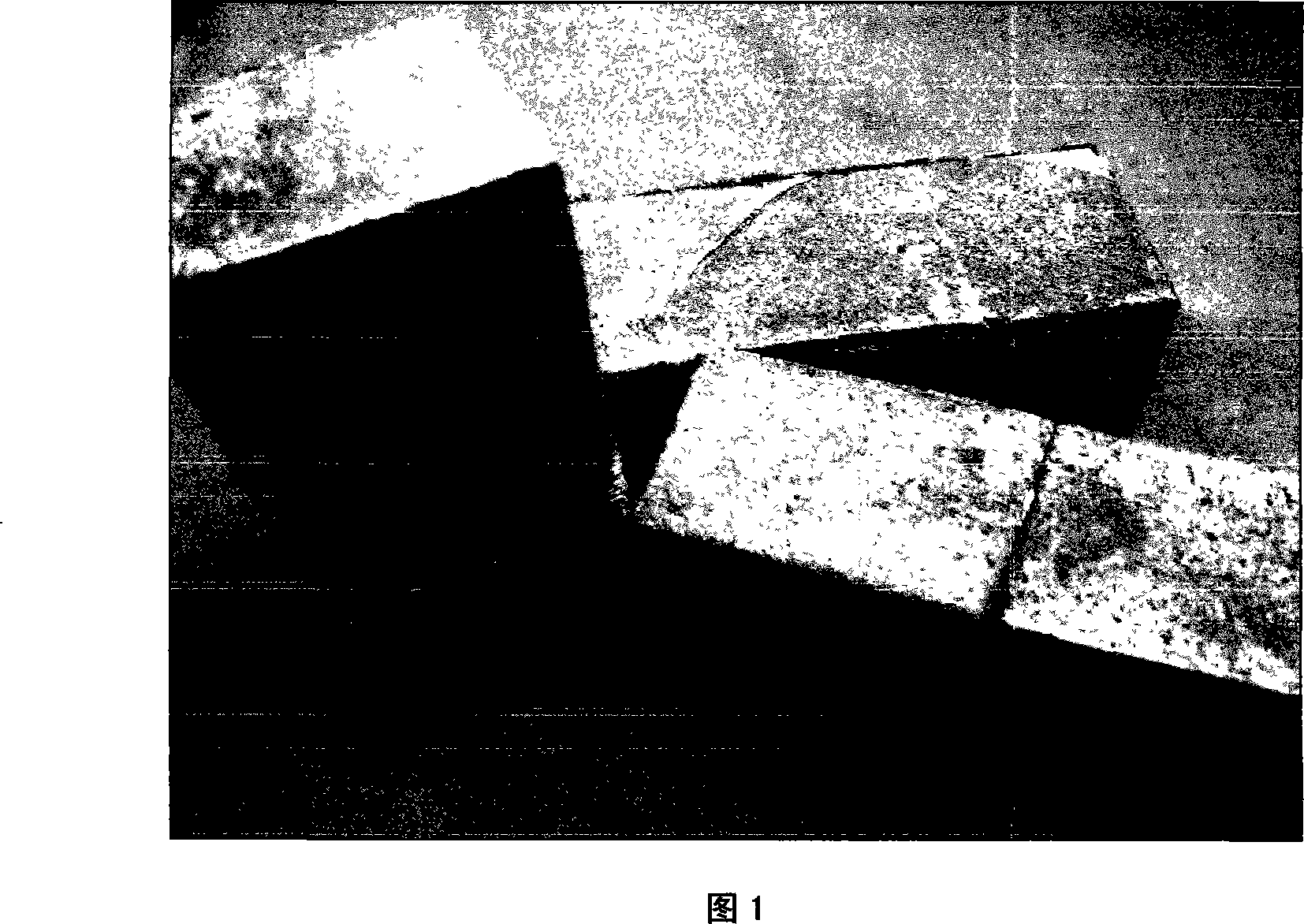

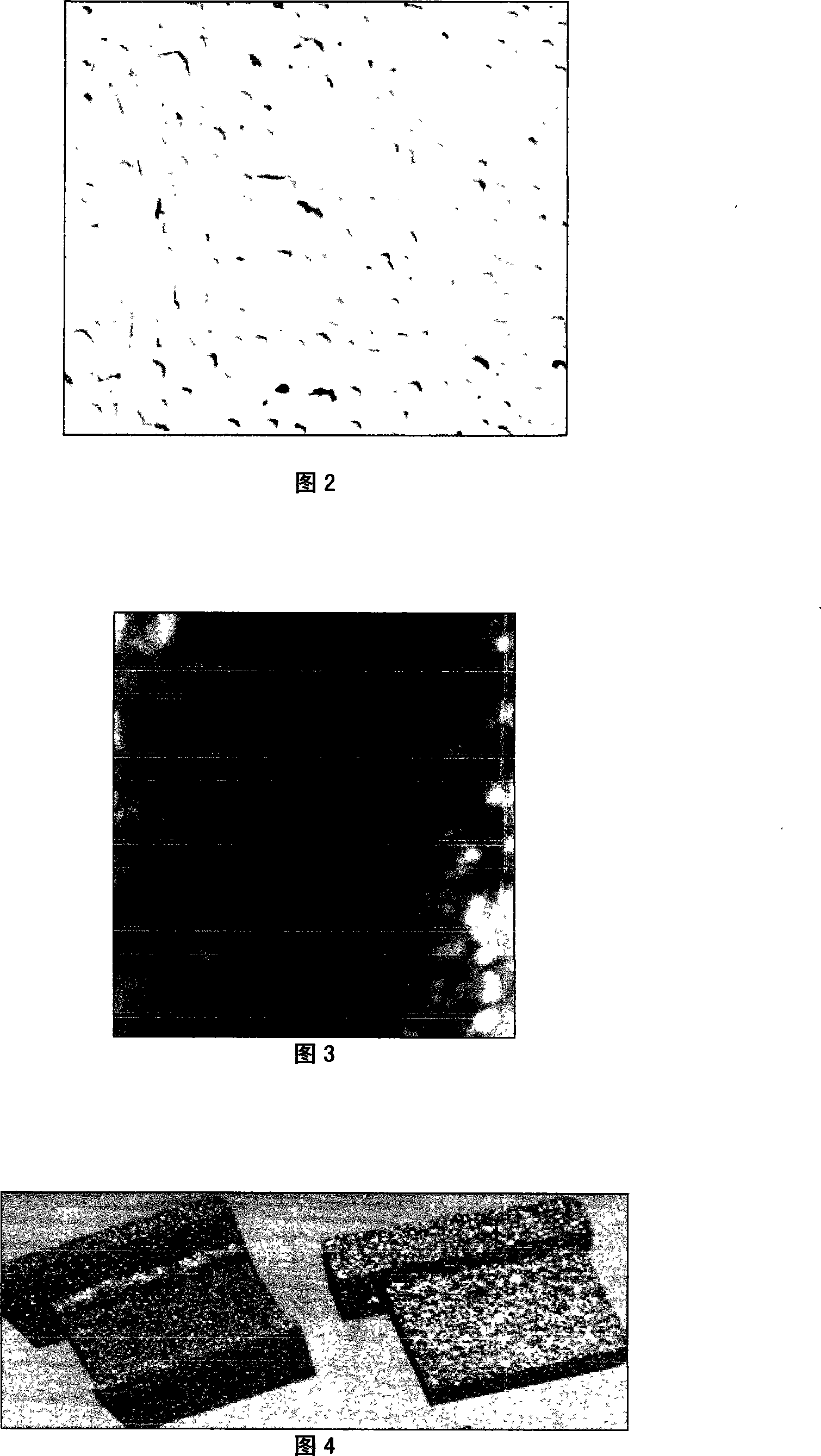

[0017] Embodiment 1: Welding of a kind of foamed aluminum alloy

[0018] The first step is to select the foamed aluminum alloy to be welded, the finish is basically flat, select the joint surface to be welded, and remove the oxide skin on the surface of the foamed aluminum alloy by grinding, without using chemical methods to clean it.

[0019] The second step is to use the positioning iron sheets to properly position and properly cover the foamed aluminum alloy, and spot weld the positioning iron sheets together to form a component covered with the foamed aluminum alloy.

[0020] The third step is to heat the above parts to 300° C. for 10 minutes for preheating, so as to prevent the uneven porosity caused by the low solid phase ratio during the welding process.

[0021] The fourth step is to put the foamed aluminum and alloy parts covered with iron sheets into the heating furnace, pass through the argon protection, and quickly raise the temperature to 650 ° C and keep it for 5...

Embodiment 2

[0023] Embodiment 2: Embodiment 1: Welding of a kind of foamed aluminum alloy

[0024] The first step is to select the foamed aluminum alloy to be welded, the finish is basically flat, select the joint surface to be welded, and remove the oxide skin on the surface of the foamed aluminum alloy by grinding, without using chemical methods to clean it.

[0025] The second step is to use the positioning iron sheets to properly position and properly cover the foamed aluminum alloy, and spot weld the positioning iron sheets together to form a component covered with the foamed aluminum alloy.

[0026] The third step is to heat the above parts to 650°C for 50 minutes for preheating, so as to prevent the uneven porosity caused by the low solid phase ratio during the welding process.

[0027] The fourth step is to put the foamed aluminum and alloy parts covered with iron sheets into the heating furnace, pass through the argon protection, and quickly raise the temperature to 1200 ° C and ...

Embodiment 3

[0029] Embodiment 3: Welding of a kind of foamed aluminum alloy

[0030] The first step is to select the foamed aluminum alloy to be welded, the finish is basically flat, select the joint surface to be welded, and remove the oxide skin on the surface of the foamed aluminum alloy by grinding, without using chemical methods to clean it.

[0031] The second step is to use the positioning iron sheets to properly position and properly cover the foamed aluminum alloy, and spot weld the positioning iron sheets together to form a component covered with the foamed aluminum alloy.

[0032] The third step is to heat the above parts to 400°C for 25 minutes for preheating, so as to prevent the uneven porosity caused by the low solid phase ratio during the welding process.

[0033] The fourth step is to put the foamed aluminum and alloy parts covered with iron sheets into the heating furnace, pass through the argon gas protection, and quickly raise the temperature to 1000 ° C and keep it fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com