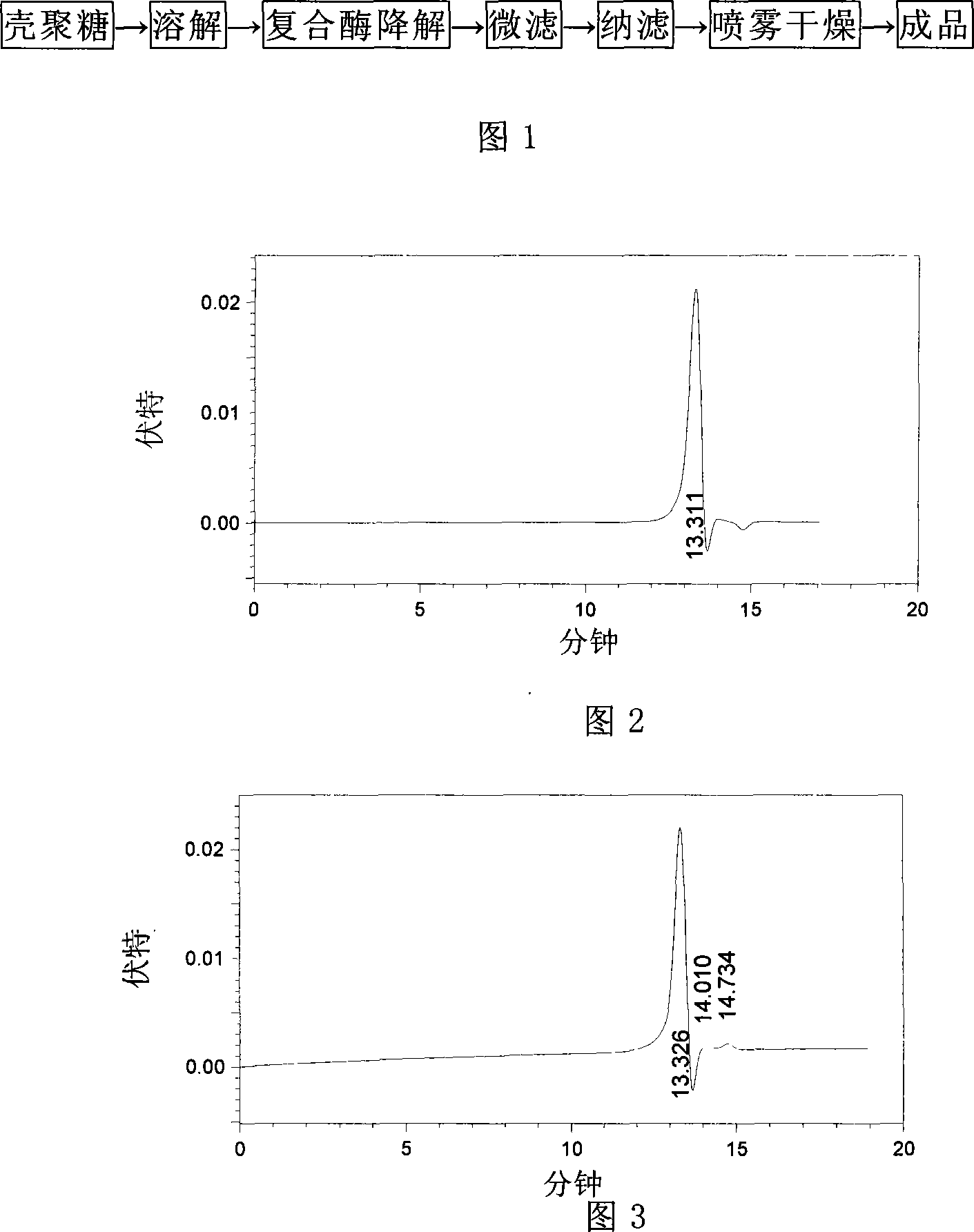

Technique for preparing oligomeric chitosan by complex enzyme degradation

A technology of chitosan oligosaccharides and process methods, which is applied in the field of chitosan oligosaccharides prepared by enzymatic methods, can solve the problems that the average molecular weight of degradation products is difficult to reach 1500 Da, the non-specific enzyme activity is limited, and the degradation time is long. Achieve the effect of improving the production environment, reducing size and operating costs, and high product activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Mix 200g of chitosan with a deacetylation degree greater than 95% (molecular weight is about 1 million Da to 600,000 Da) in 10L of water under stirring, add glacial acetic acid with a concentration of >99.5% to dissolve chitosan and adjust the solution The pH value is 4.5, the temperature is raised to 50°C, 12g of α-amylase is added, and 12g of bromelain is added after constant temperature reaction for 0.5h, and the constant temperature reaction is continued for 3.5h, and the discharge is cooled to room temperature; the obtained chitosan degradation solution is 10L, Its pH value is 4.7, add deionized water to dilute to 20L, and then use hollow fiber components for microfiltration; the operating conditions of microfiltration are: operating pressure difference 0.06-0.08MPa, operating temperature is room temperature, and every 0.5h in the microfiltration process Add 5L of deionized water to the feed liquid, and the total amount of added water is 10L; the microfiltration per...

Embodiment 2

[0031] Mix 200g of chitosan with a deacetylation degree greater than 95% (molecular weight is about 1 million Da to 600,000 Da) in 10L of water under stirring, add glacial acetic acid with a concentration of >99.5% to dissolve chitosan and adjust the solution The pH value is 4.6, warm up to 35°C, add 12g of α-amylase, react at a constant temperature for 0.5h, then add 12g of cellulase, continue the reaction at a constant temperature for 3.5h, and cool the material to room temperature; the obtained chitosan degradation solution is 10L , whose pH value is 4.8, dilute to 20L with deionized water, and then use hollow fiber components for microfiltration; the operating conditions of microfiltration are: operating pressure difference 0.06-0.08MPa, operating temperature is room temperature, and every 0.5 h Add 5L of deionized water to the feed liquid, and the total amount of added water is 10L; the microfiltration permeate is heated to 30°C and the concentrated volume of nanofiltratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com