Reducing chamber and heating chamber multilayer obturation alternation and fusion gasification combination metal smelting method

A heating chamber and metal technology, applied in the field of iron smelting, can solve the problems of small scale of single equipment, low carbon content in molten iron, high combustion temperature, etc., to solve the problem of short life of furnace lining, reduce energy consumption, and reduce specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

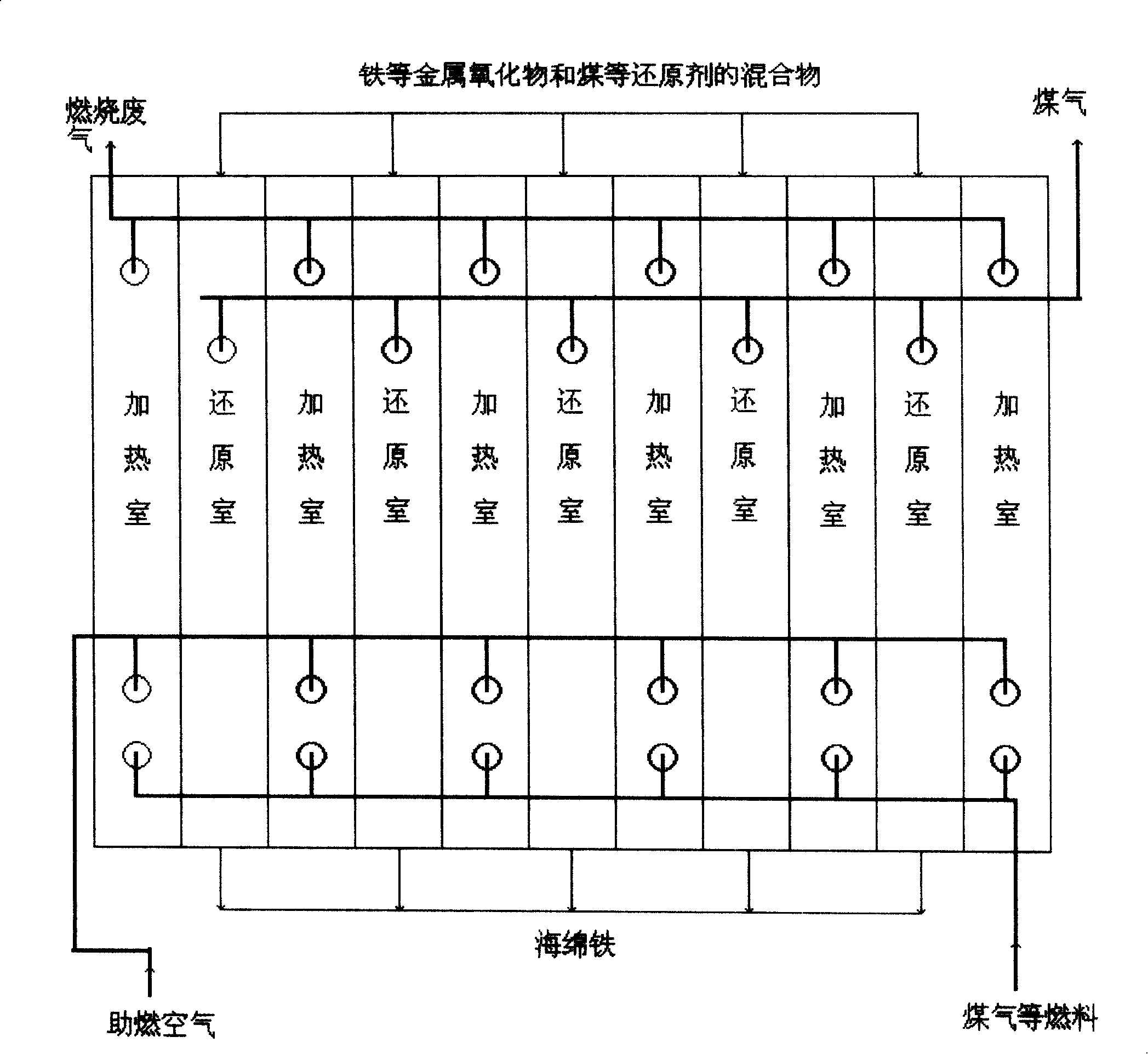

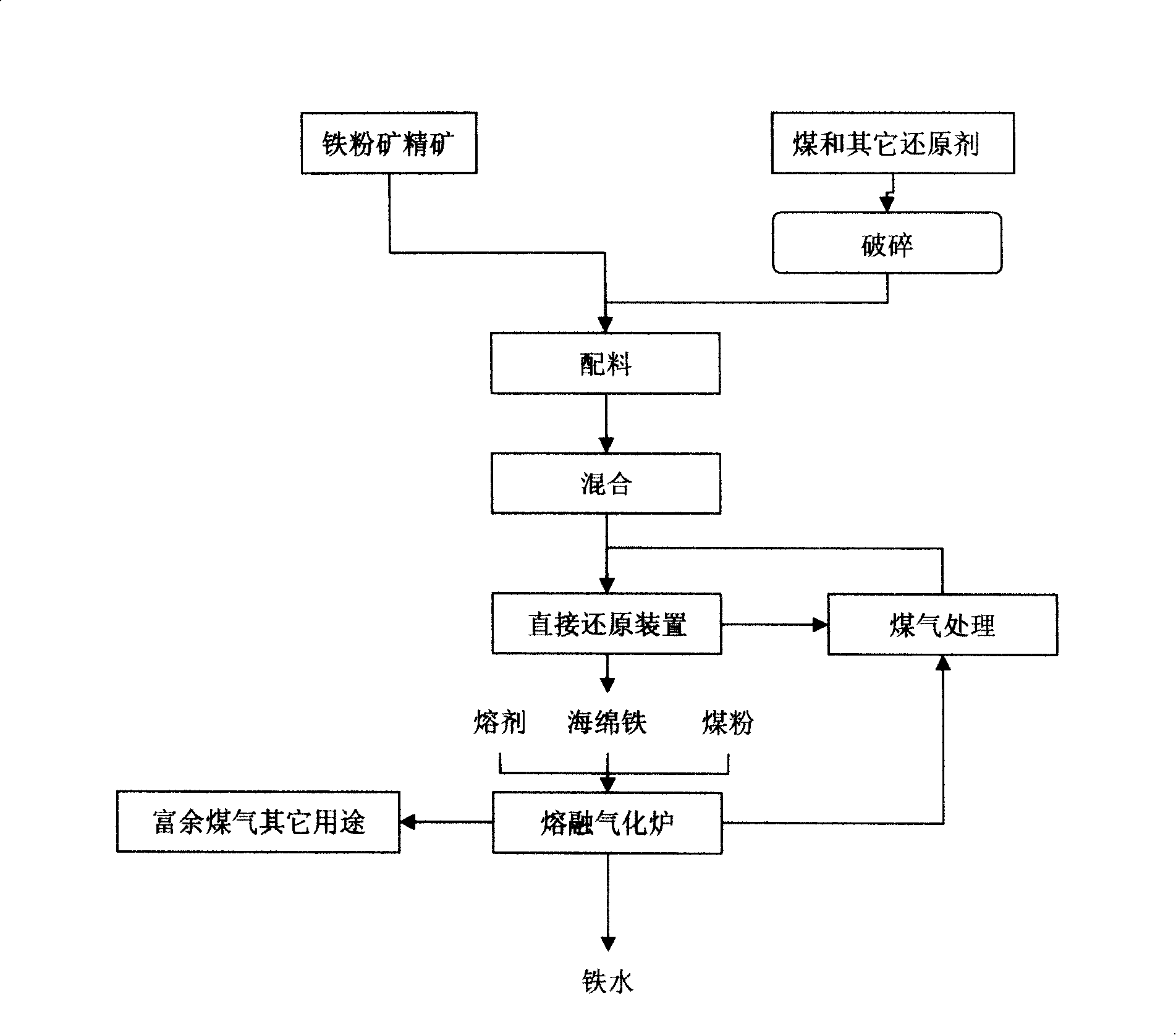

[0037] In Figure 1, the ratio of combustion-supporting air to gas and other fuels must maintain a certain excess air coefficient, and select appropriate burners according to the nature of the fuel. The number and distribution of burners must meet the requirements of uniform temperature in the heating chamber. Except for the fuel with high impurity content, other fuels and combustion air should be preheated, and the heat of preheating comes from the combustion exhaust gas in the heating chamber. All the walls between the heating chamber and the reduction chamber are generally built with 100-300mm silica bricks to ensure good airtightness.

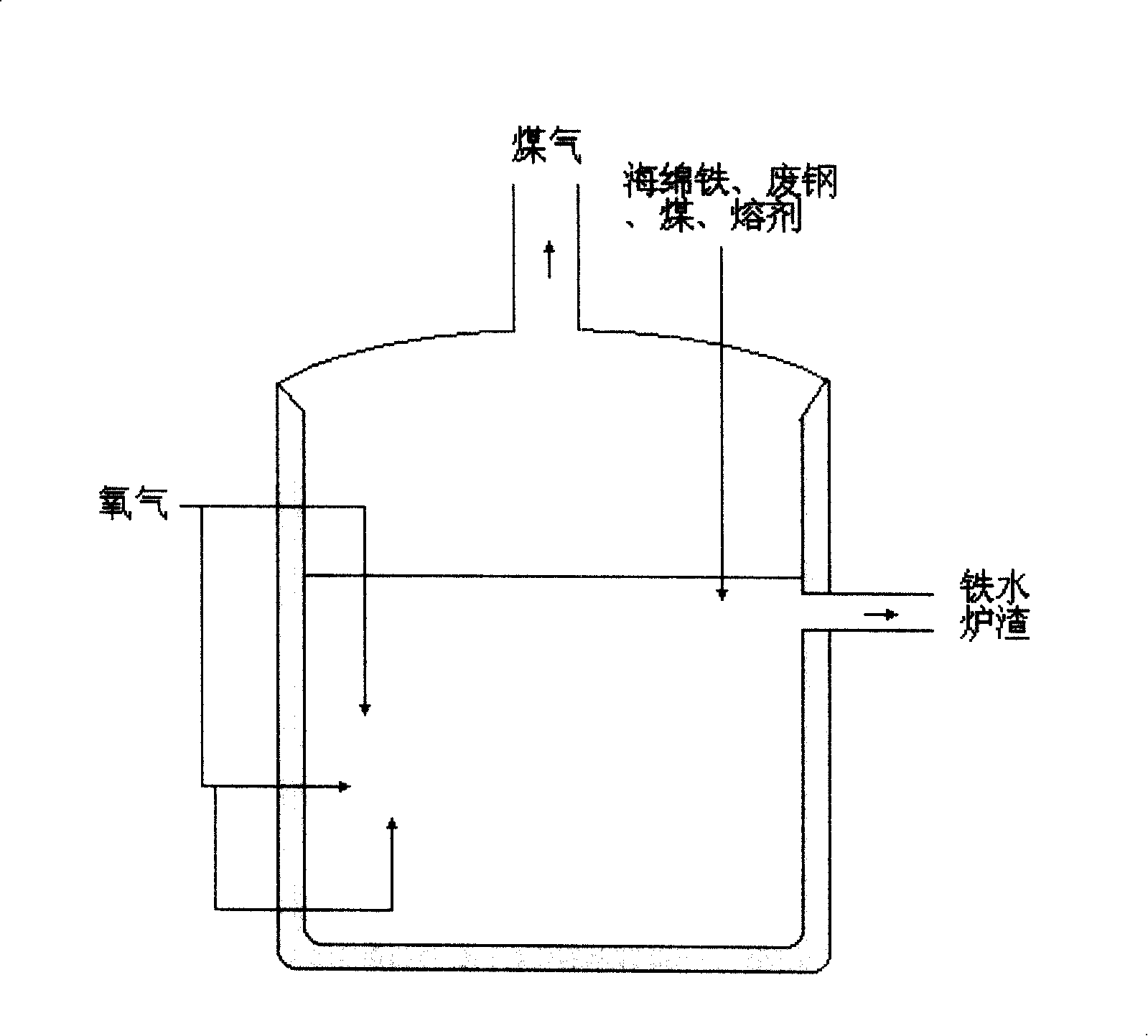

[0038] In Figure 2, the flux and metal materials can be put in from above the molten iron, the coal powder should generally be blown into the molten iron, and the oxygen must be blown into the molten iron. The upper part of the gasifier is a closed structure for gas recovery. The main body of the furnace body generally adopts a fixed structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com