Method for preparing film surface of nanometer-stage thickness on red copper surface

A copper and thin film technology, applied in the direction of metal material coating process, can solve the problems of complex equipment, high cost, difficult industrialization, etc., and achieve the effect of reducing surface energy, easy to grasp, and uniform and dense thin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

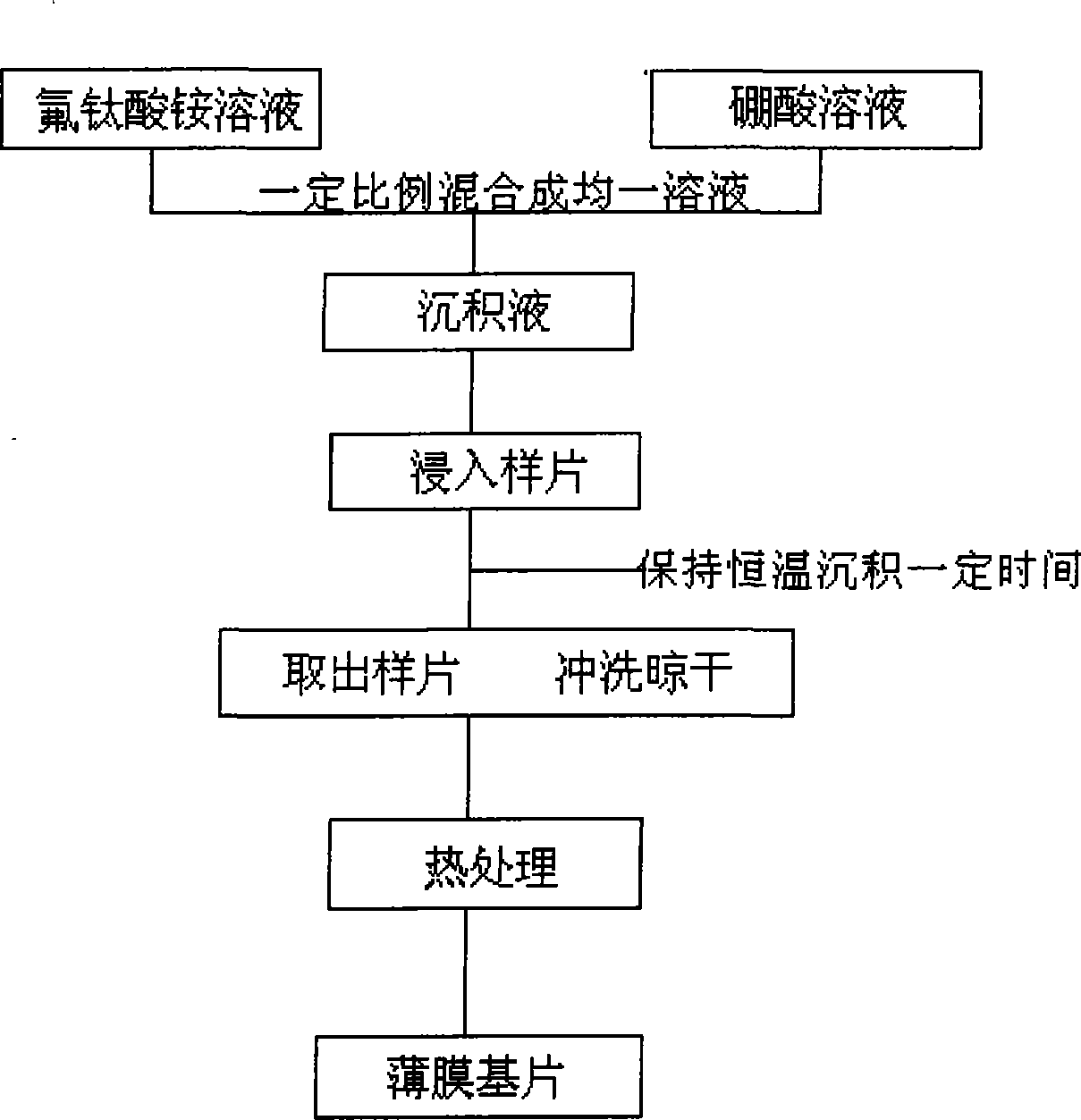

Method used

Image

Examples

Embodiment 1

[0020] (a) carry out pretreatment to copper substrate, utilize 300 at first # The copper base is polished with emery, and after the entire surface of the copper is covered with black emery, 500 # The corundum continues to grind the above substrate until 500 # The corundum replaces the original 300 tiled on the substrate # until the emery particles are evenly spread on the copper substrate; then use 4μm emery paste for mechanical polishing until all the black emery on the substrate is removed, and then use 0.5μm emery paste to continue polishing until the surface is invisible to the naked eye until it is scratched; then use 3% by mass of dilute hydrochloric acid to soak the substrate for 30 minutes to remove the oxide on the surface; then immerse the substrate in 10% by mass of sodium hydroxide solution for 20 minutes to remove some Grease; take out the substrate, put an appropriate amount of detergent on it, and repeatedly scrub it with absorbent cotton. After scrubbing, rin...

Embodiment 2

[0022] (a) carry out pretreatment to copper substrate, utilize 200 at first # Grinding the copper base with emery, and after the entire surface of the copper is covered with black emery, use 550 # The corundum continues to grind the above substrate until 550 # The corundum replaces the original 200 tiled on the base # until the emery particles are evenly spread on the copper substrate; then use 1 μm emery paste for mechanical polishing until all the black emery on the substrate is removed, and then use 0.9 μm emery paste to continue polishing until the surface is invisible to the naked eye until it is scratched; soak the substrate with 2% by mass of dilute hydrochloric acid for 5 minutes to remove the oxide on the surface; then immerse the substrate in 5% by mass of sodium hydroxide solution for 5 minutes to remove some Grease; take out the substrate, put an appropriate amount of detergent on it, and repeatedly scrub it with absorbent cotton. After scrubbing, rinse the subst...

Embodiment 3

[0024] (a) carry out pretreatment to copper substrate, utilize 400 at first # Polish the copper base with emery, and after the entire surface of the copper is covered with black emery, use 600 # The corundum continues to grind the above substrate until 600 # The corundum replaces the original 200 tiled on the base # until the emery particles are evenly spread on the copper substrate; then use 3μm emery paste for mechanical polishing until all the black emery on the substrate is removed, and then use 1μm emery paste to continue polishing until the surface cannot be scratched by naked eyes Then soak the substrate with 1% by mass of dilute hydrochloric acid for 10 minutes to remove surface oxides; then immerse the substrate in 15% by mass of sodium hydroxide solution for 25 minutes to remove part of the grease Take out the substrate, put an appropriate amount of detergent on it, and repeatedly scrub with absorbent cotton. After scrubbing, rinse the substrate with distilled wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com