Process for producing mangano-manganic oxide nanocrystalline with controllable sizing and shape

A nano-size technology of manganese tetraoxide, which is applied in nanostructure manufacturing, manganese oxide/manganese hydroxide, nanotechnology, etc., can solve the problems of nanoparticle dispersion and large particle size, and achieve mild reaction conditions and short preparation cycle , The effect of the method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

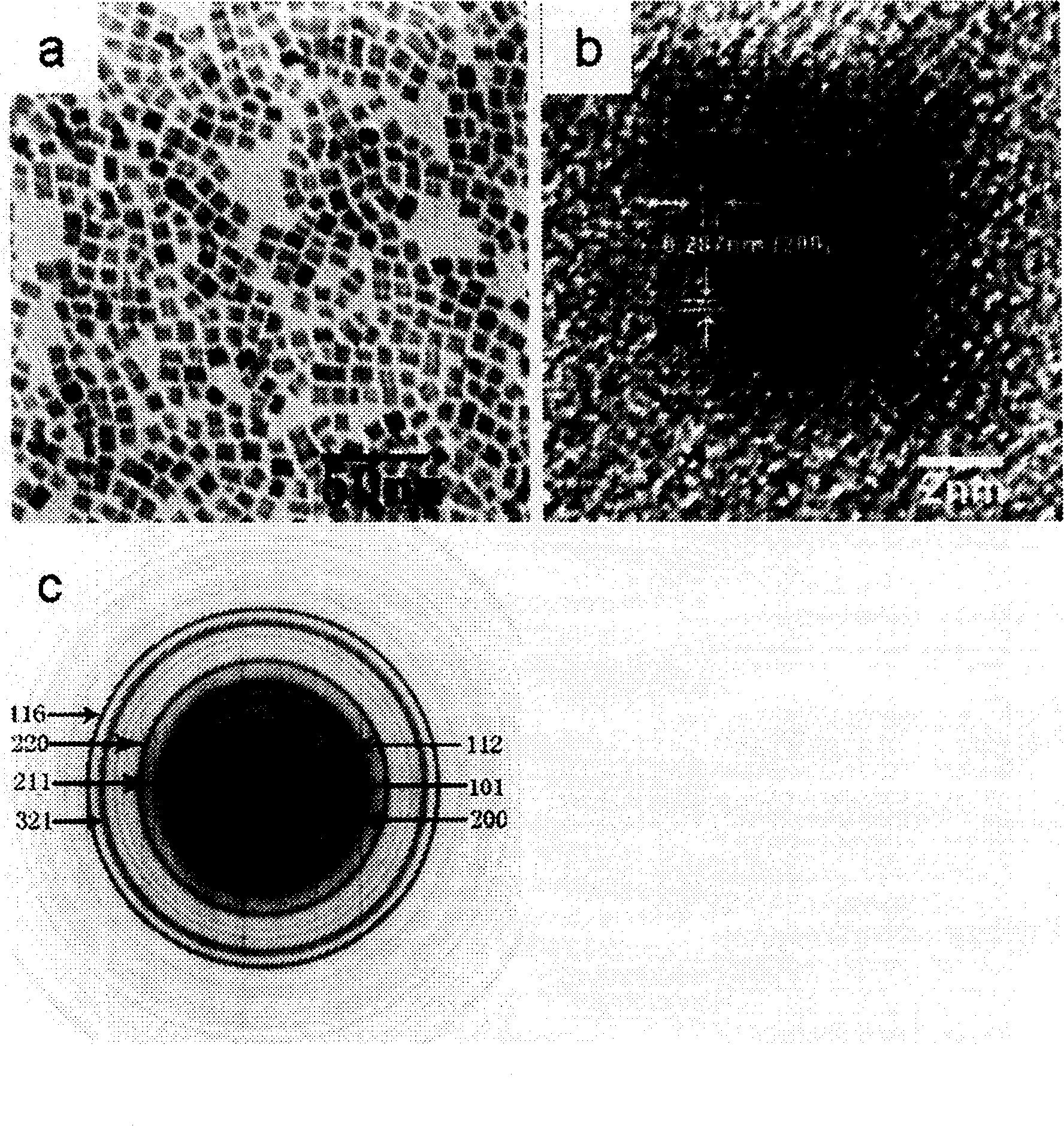

[0012] Embodiment 1: preparation of spherical (3nm) organic ligand-coated trimanganese tetraoxide nanocrystals

[0013] Add 62 mg of manganese stearate, 1.0 ml of oleylamine and 5 ml of toluene to the polytetrafluoroethylene lining of a 30 ml autoclave, then add 15 ml of an aqueous solution containing 0.4 ml of tert-butylamine to the system, seal the autoclave and put it in the furnace Heating at 180°C for 4 hours (the pressure is maintained at 1-10MPa), and after cooling, brown spherical manganese tetraoxide nanocrystals coated with organic ligands are formed in the oil phase. Its particle size is about 3nm.

Embodiment 2

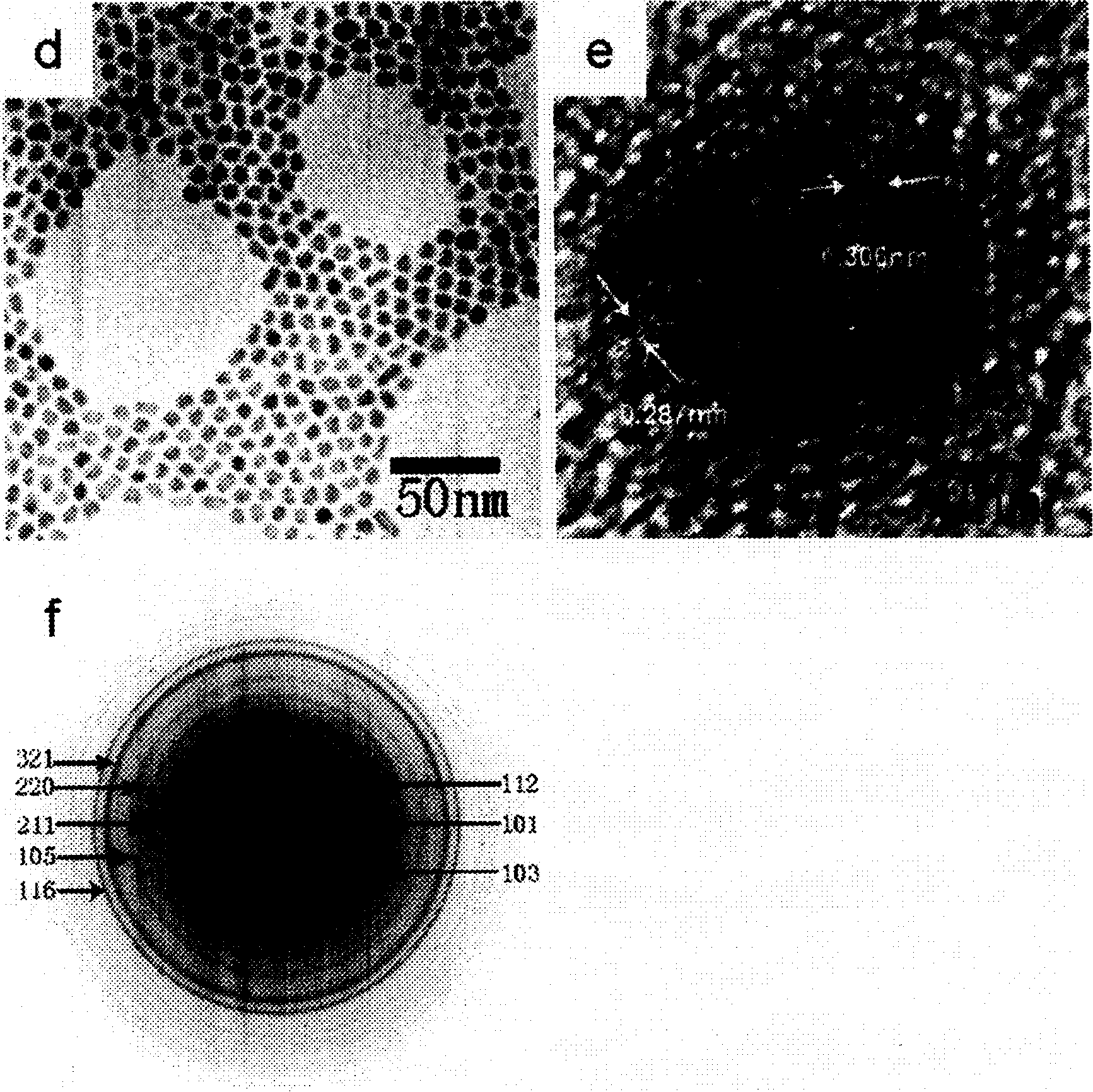

[0014] Embodiment 2: the preparation of square (15nm) trimanganese tetraoxide nanocrystals

[0015] Add 62 mg of manganese myristate, 0.5 ml of oleic acid and 10 ml of toluene to the polytetrafluoroethylene lining of a 30 ml autoclave, then add 10 ml of an aqueous solution containing 0.10 ml of tributylamine to the system, seal the autoclave and put Heating in the furnace at 120°C for 2 hours, (the pressure is maintained at 1-10MPa) and cooling, brown square-shaped manganese tetraoxide nanocrystals coated with organic ligands are formed in the oil phase. Its particle size is about 15nm.

Embodiment 3

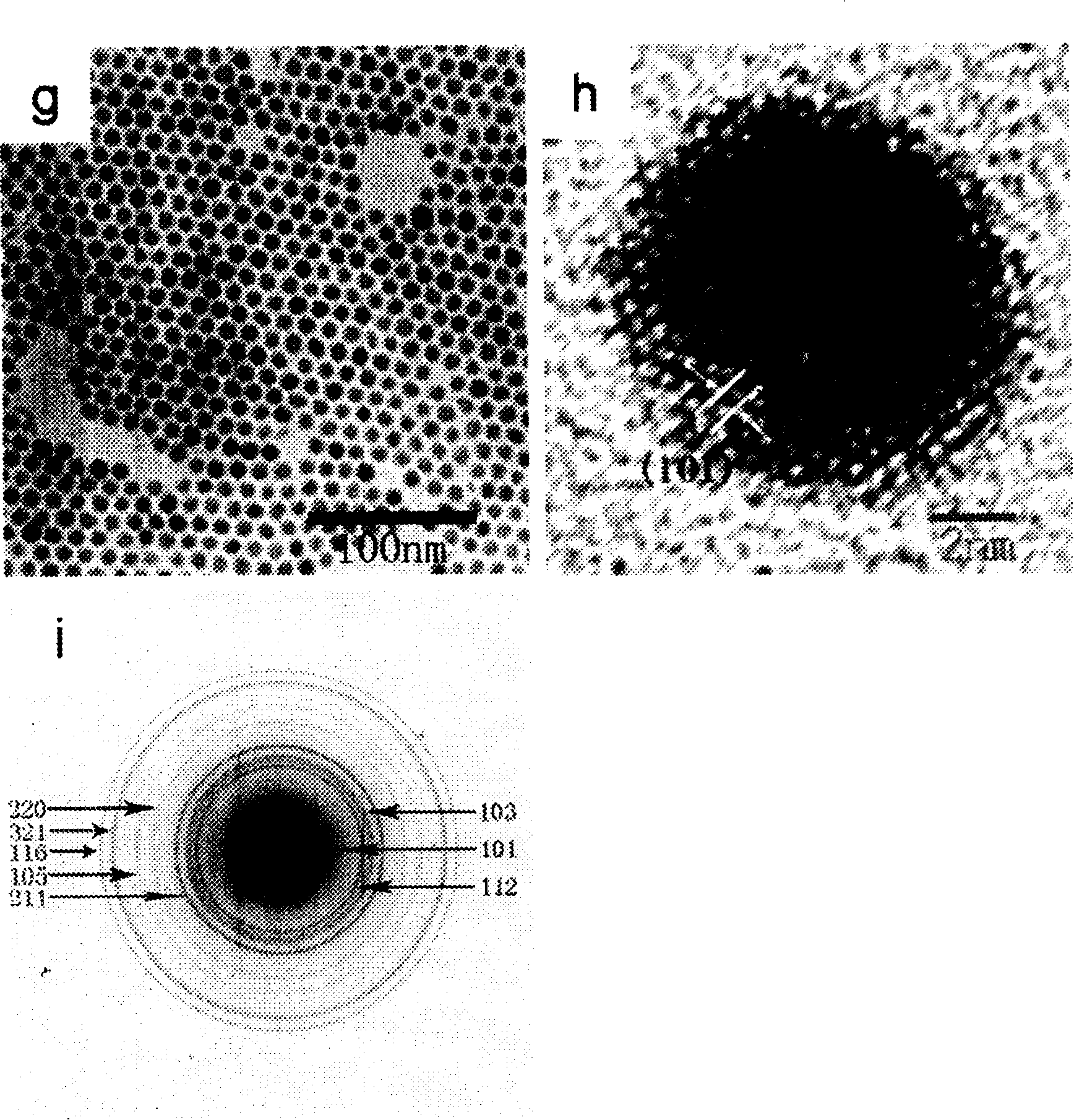

[0016] Embodiment 3: the preparation of square (9nm) trimanganese tetraoxide nanocrystal

[0017] Add 62 mg of manganese oleate, 0.5 g of stearic acid and 5 ml of toluene into the polytetrafluoroethylene lining of a 30 ml autoclave and heat until it is colorless and transparent. After cooling to room temperature, add 15.0 ml of an aqueous solution containing 0.4 ml of tert-butylamine Add the system, seal the autoclave and put it into the furnace to heat at 100°C for 8 hours (the pressure is maintained at 1-10MPa). After cooling, brown square-shaped manganese tetraoxide nanocrystals coated with organic ligands are formed in the oil phase. Its particle size is about 9nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com