Container formed by stretch forming and process for producing the same

A technology for stretch forming and containers, applied in the field of stretch forming containers and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

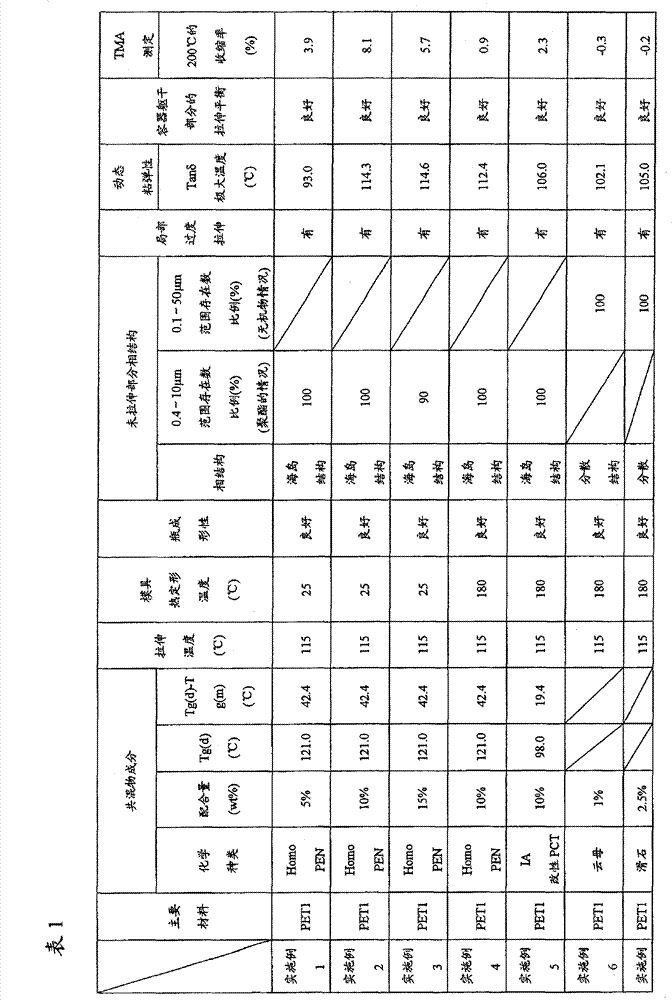

Embodiment 1

[0180] Polyethylene terephthalate resin ([PET 1] (RT543CTHP: Japan Unipet Co., Ltd.) is used as the main material, and polyethylene naphthalate resin [HomoPEN] (TN8065S: Teijin )) As the type of blend polyester, dry-mixing is carried out in the ratio of main material: blend polyester type=95:5 by weight, and the material is fed to the hopper of the injection molding machine. Under the condition of a cycle time of 30 seconds, injection molding was performed to obtain a preform for a bottle with a diameter of 28 mm.

[0181] The mouth portion of the preform was crystallized and whitened in advance, and then biaxially stretch-blow-molded to obtain a stretch-blow bottle with a volume of 500 ml. In this case, the heating temperature of the preform, that is, the stretching temperature was set to 115°C, and the heat setting temperature of the blow mold was set to room temperature (25°C).

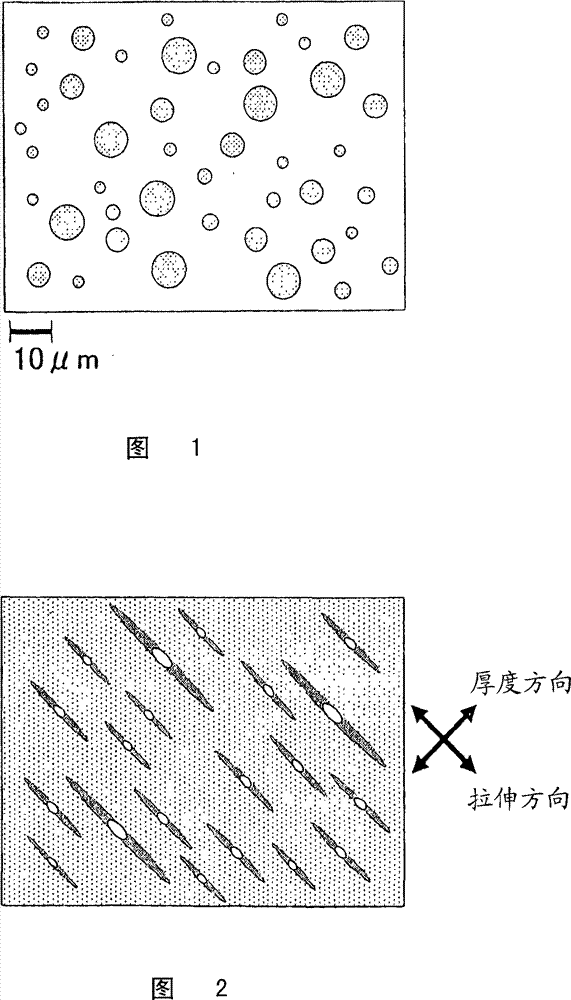

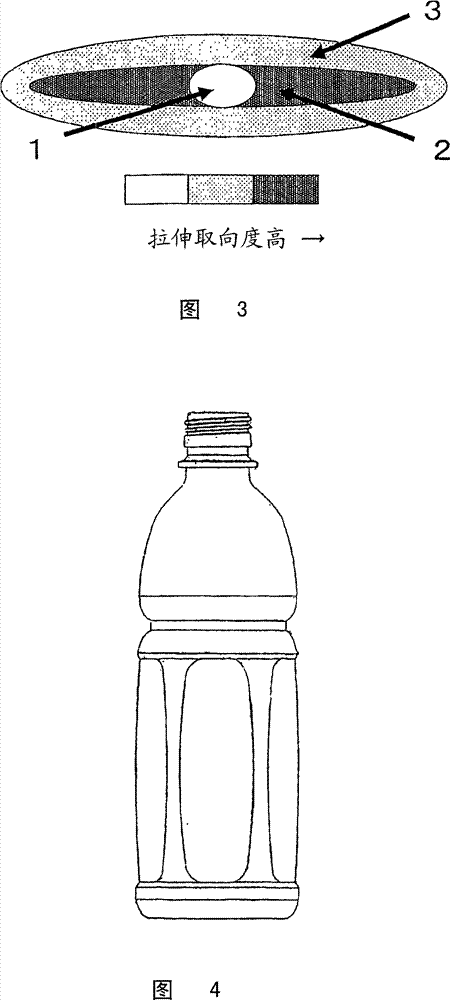

[0182] Cut out various parts of the bottle, and measure the following items in the above-menti...

Embodiment 2

[0190] Main material by weight ratio: the ratio of blend polyester type=90:10, the materials are dry mixed, and fed to the hopper of the injection molding machine. In addition, other stretch blow blowers are made in the same way as in Example 1. Plastic bottle, carries out every measurement described in embodiment 1.

Embodiment 3

[0192] Main material by weight: the ratio of blend polyester type = 85: 15, the materials are dry mixed, and fed to the hopper of the injection molding machine. In addition, the stretch blow molding is made in the same way as in Example 1. bottle, and carry out the various assays described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com