Preparing method of core-shell TiO2/ZnO photocatalyst and applications thereof

A photocatalyst, 2·2H2O technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effect of effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

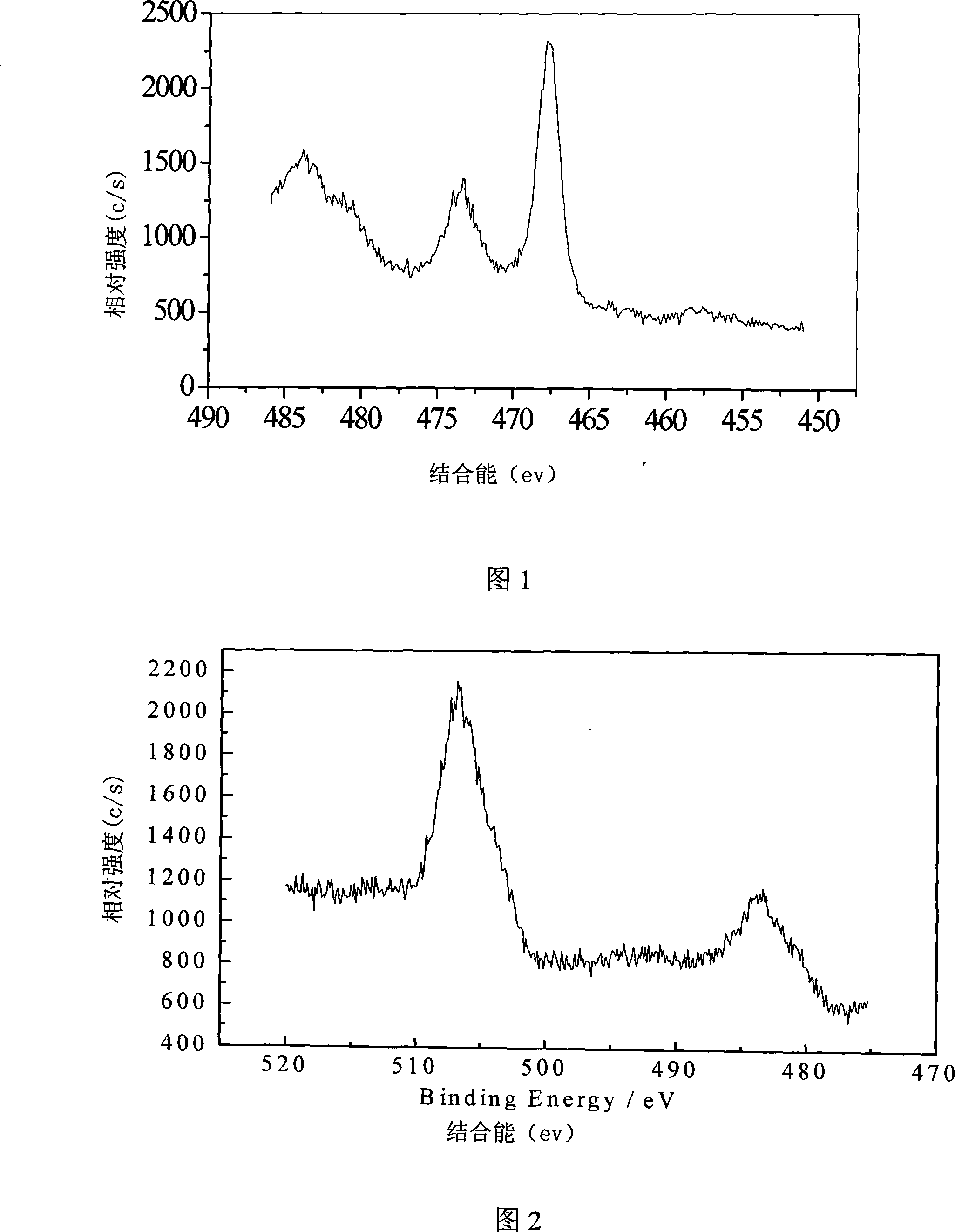

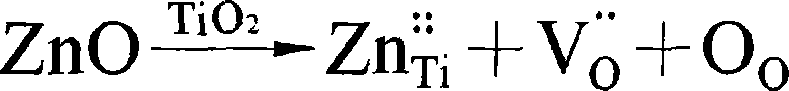

Image

Examples

specific Embodiment approach 1

[0009] Specific implementation mode 1: In this embodiment, core-shell type TiO 2 The steps of the / ZnO photocatalyst preparation method are as follows: one, according to Zn(CH 3 COO) 2 2H 2 The mass ratio of O to polyvinyl alcohol is 2:1 to make Zn(CH 3 COO) 2 2H 2 O is dissolved in a polyvinyl alcohol solution with a weight concentration of 4-6%, mixed in a water bath at 80-100°C and stirred at a speed of 150-200r / min for 0.5-1 hour, and then mixed at 100-120°C Dry under low temperature for 1-2 hours, heat the dried product to 300°C for 0.5-1 hour, continue to heat up to 400°C for 0.5-1 hour, then raise the temperature to 550°C for 0.5-1 hour, and then cool it to room temperature in the air 2. After mixing and stirring 1-2 parts by weight of tetrabutyl titanate, 4-5 parts by weight of absolute ethanol and 0.1-0.3 parts by weight of triethanolamine for 1.5-2 hours, aging for 0.5-1 hours, press The mass ratio of the product to tetrabutyl titanate in step 1 is 2-4:1. Add th...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step two, 1.1-1.5 parts by weight of tetrabutyl titanate, 4.1-4.5 parts by weight of absolute ethanol and triethanolamine of 0.11-0.2 parts by weight Mix, and others are identical with specific embodiment one.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step two, 1.6-1.9 parts by weight of tetrabutyl titanate, 4.6-4.9 parts by weight of absolute ethanol and triethanolamine of 0.21-0.29 parts by weight Mix, and others are identical with specific embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com