Method for preparing Fe doped ZnO room-temperature diluted magnetic semiconductor material

A dilute magnetic semiconductor, room temperature technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of obtaining room temperature ferromagnetism, and achieve the effect of easy operation, good repeatability and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

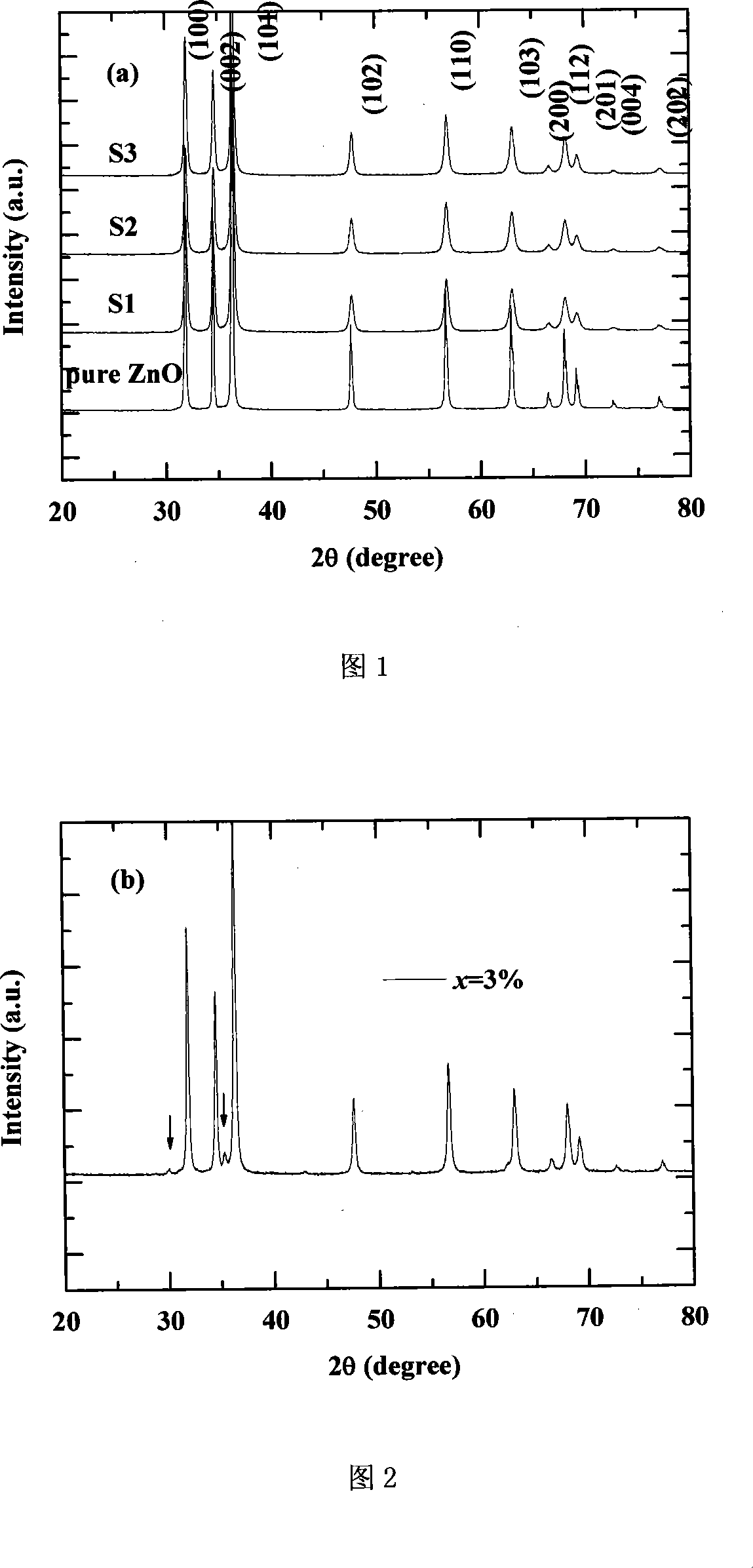

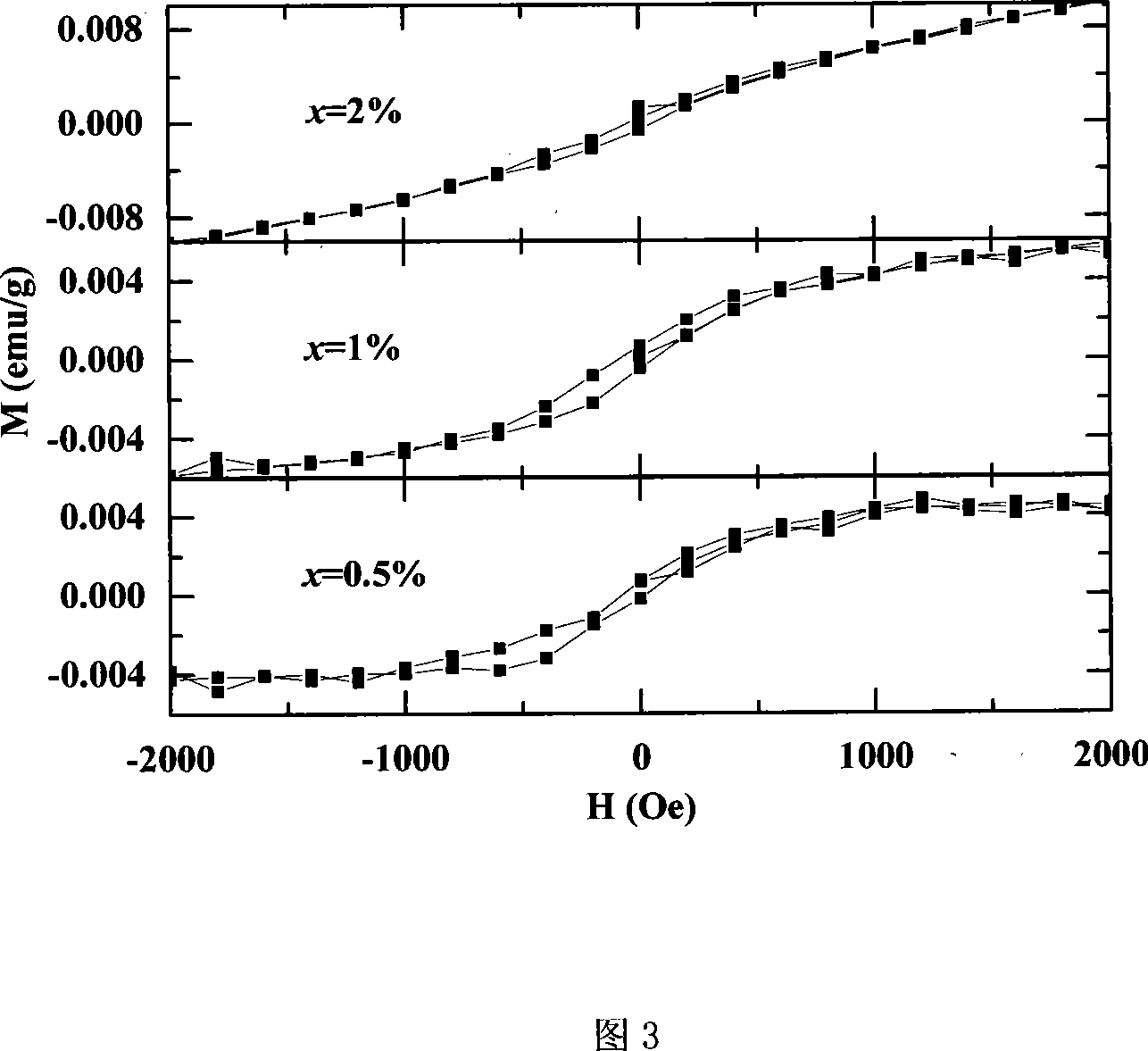

Embodiment 1

[0014] Preparation of 0.03mol room temperature dilute magnetic semiconductor Zn by using the present invention 1-x Fe x O(x=0.005) material. The first step is to weigh and analyze pure Zn(NO 3 ) 2 ·6H 2 O powder 8.92g and Fe(NO 3 ) 3 9H 2 O powder 0.0606g, of which Fe 3+ The doping concentration is 0.1%, put it in a beaker, add 200ml deionized water to dissolve it completely, and form Fe 3+ and Zn 2+ Mixed solution; according to NO 3 - Ion moles (0.06042mol) and OH - The number of moles of ions is 1:1. Weigh 2.4168g of analytically pure NaOH powder and add 100ml of deionized water to prepare a NaOH solution. In the second step, pour the prepared NaOH solution into Fe 3+ and Zn 2+ In the mixed solution, keep stirring, add ammonia water dropwise at the same time, control the pH=8 of solution, make Fe 3+ and Zn 2+ complete precipitation, forming Fe(OH) 3 and Zn(OH) 2 The precipitates were mixed; the precipitates were filtered, washed 5 times with deionized water...

Embodiment 2

[0016] Preparation of 0.01 mol room temperature dilute magnetic semiconductor Zn by using the present invention 1-x Fe x O(x=0.01) material. The first step is to weigh and analyze pure Zn(NO 3 ) 2 ·6H 2 O powder 2.945g and Fe(NO 3 ) 3 9H 2 O powder 0.0404g, of which Fe 3+ The doping concentration is 1%, put it in a beaker, add 200ml deionized water to dissolve it completely, and form Fe 3+ and Zn 2+ Mixed solution; according to NO 3 - Ion moles (0.101mol) and OH - The number of moles of ions is 1:1. Weigh 0.804g of analytically pure NaOH powder and add 100ml of deionized water to prepare a NaOH solution. In the second step, pour the prepared NaOH solution into Fe 3+ and Zn 2+ In the mixed solution, keep stirring, add ammonia water dropwise at the same time, control the pH=8 of solution, make Fe 3+ and Zn 2+ complete precipitation, forming Fe(OH) 3 and Zn(OH) 2 The precipitates were mixed; the precipitates were filtered, washed 5 times with deionized water, an...

Embodiment 3

[0018] Preparation of 0.05 mol room temperature dilute magnetic semiconductor Zn by using the present invention 1-x Fe x O(x=0.02) material. The first step is to weigh and analyze pure Zn(NO 3 ) 2 ·6H 2 O powder 14.5765g and Fe(NO 3 ) 3 9H 2 O powder 0.404g, of which Fe 3+ The doping concentration is 2%, put it in a beaker, add 300ml deionized water to dissolve it completely, and form Fe 3+ and Zn 2+ Mixed solution; according to NO 3 - Ion moles (0.101mol) and OH - The number of moles of ions is 1:1. Weigh 4.04g of analytically pure NaOH powder and add 100ml of deionized water to prepare a NaOH solution. In the second step, pour the prepared NaOH solution into Fe 3+ and Zn 2+ In the mixed solution, keep stirring, add ammonia water dropwise at the same time, control the pH=9 of solution, make Fe 3+ and Zn 2+ complete precipitation, forming Fe(OH) 3 and Zn(OH) 2 The precipitates were mixed; the precipitates were filtered, washed 5 times with deionized water, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com