Colored photosensitive resin composition

A technology of photosensitive resin and composition, which is applied in optics, optical components, optomechanical equipment, etc., can solve the problems of unsatisfactory ink repellency and achieve the effect of improving ink repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

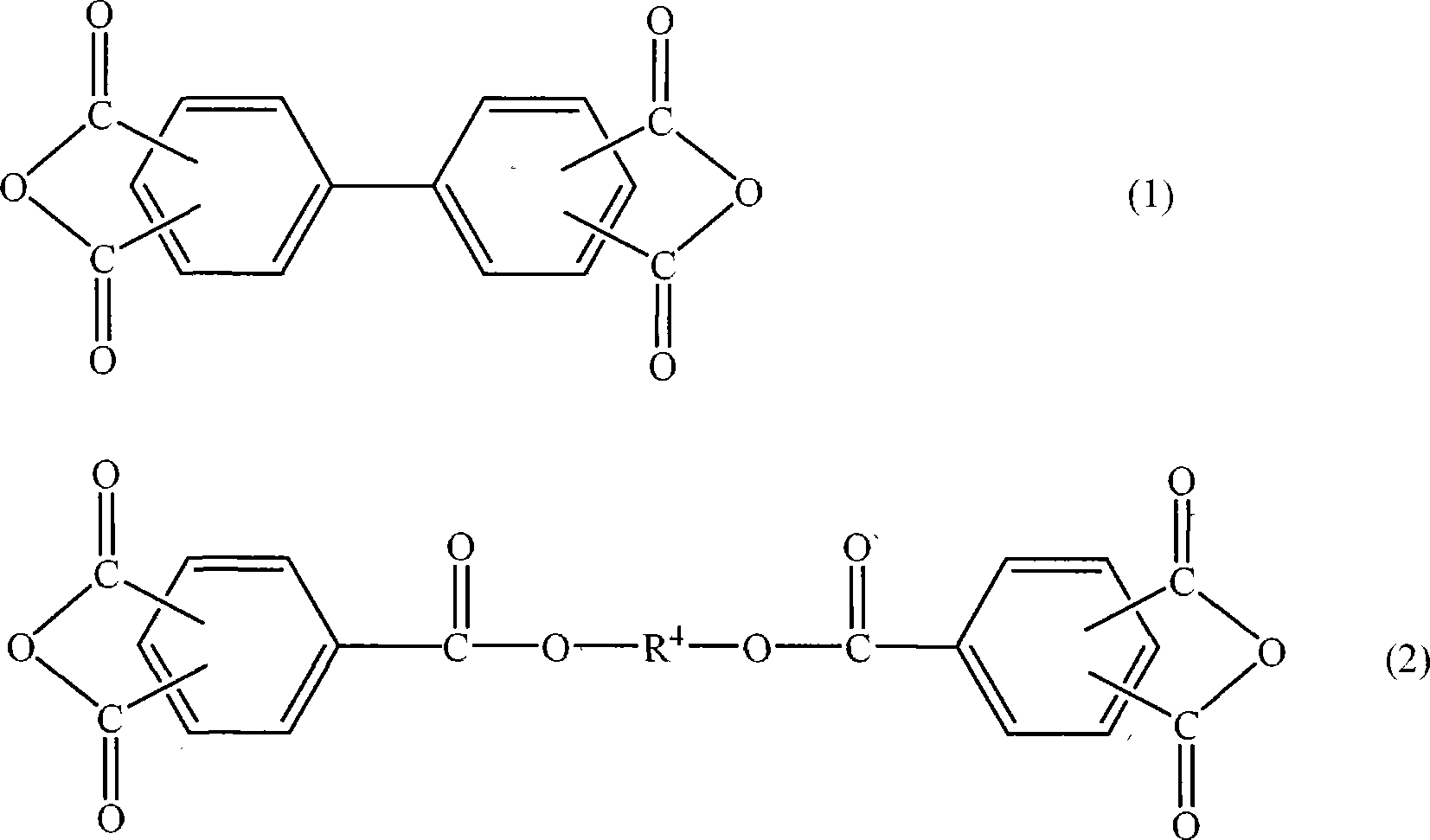

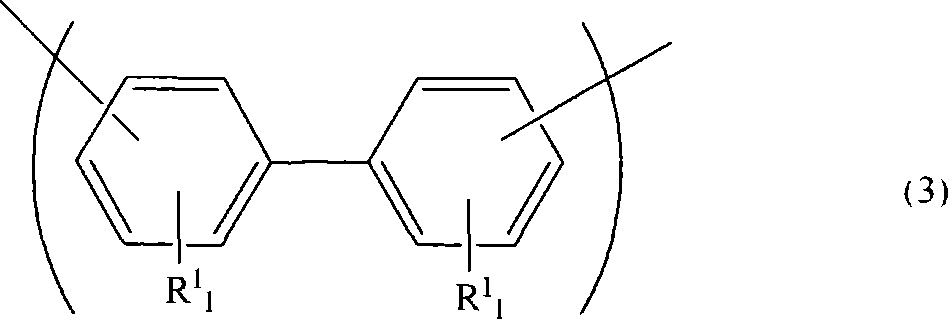

Method used

Image

Examples

preparation example Construction

[0111] [Manufacturing method of colored photosensitive resin composition]

[0112] The colored photosensitive resin composition of the present invention is obtained by mixing all the above-mentioned components with a mixer. In addition, it is also possible to filter with a filter in order to homogenize the obtained mixture.

[0113] [Manufacturing method of color filter]

[0114] First, use a contact transfer coating device such as a roll coater, a reverse coater, or a bar coater, or a spin coater (Spinner, spin coater), or a curtain coater A non-contact coating device such as a flow coater) coats the colored photosensitive resin composition of the present invention on a substrate. As the substrate, a light-transmitting substrate is used.

[0115] Next, the applied colored photosensitive resin composition is dried to form a coating film. The drying method is not particularly limited, for example, any one of the following methods can be adopted: (1) a method of drying at a ...

Embodiment 1

[0122] Resin (A-1) and monomer (A-3) pentaerythritol tetraacrylate were used as a photopolymerizable compound (A).

[0123] [Synthesis of resin (A-1)]

[0124] The synthesis of resin (A-1) is as follows.

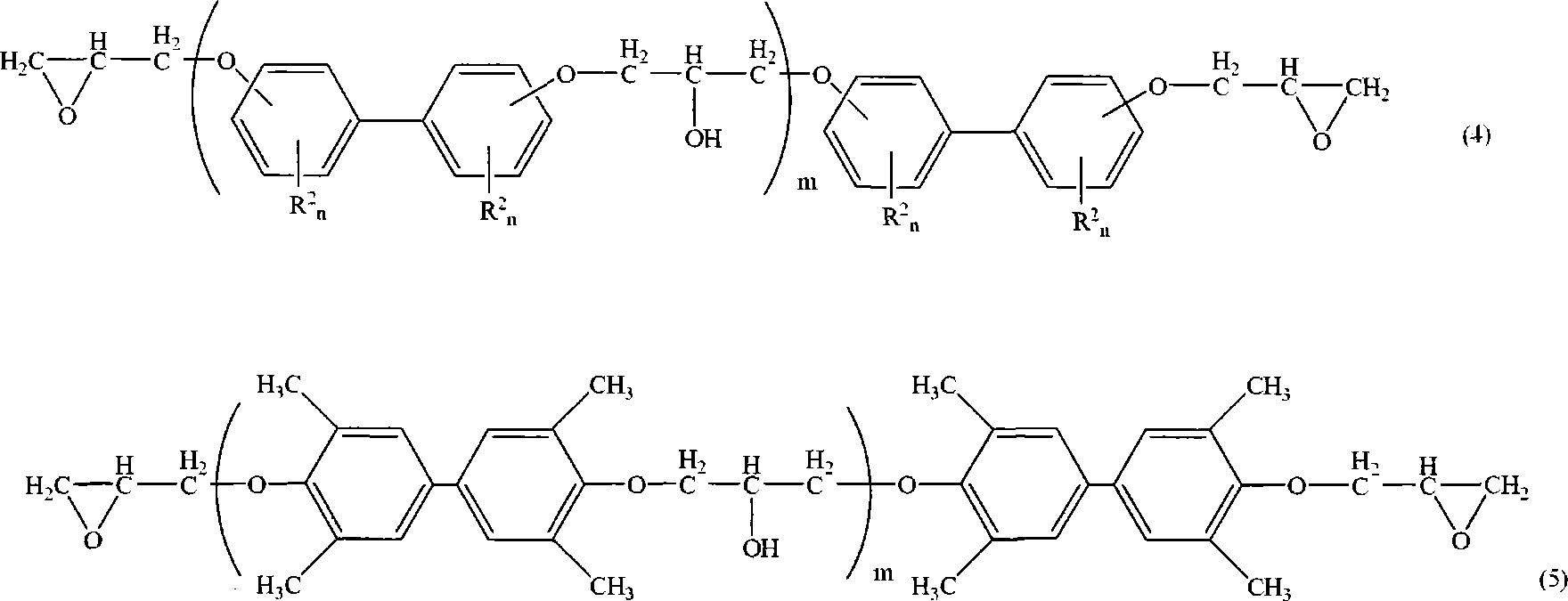

[0125] Blow in air at a speed of 25 ml / min, simultaneously with 235g bisphenol fluorene type epoxy resin (epoxy equivalent is 235), 110mg tetramethylammonium chloride, 100mg 2,6-di-tert-butyl-4-methyl The base phenol and 72.0 g of acrylic acid were melted by heating at 90°C to 100°C, and then the temperature was gradually raised to 120°C. At this point, the acid value was measured, and heating and stirring was continued for about 12 hours until the acid value became less than 1.0 mgKOH / g. Then, it was cooled to room temperature to obtain a colorless and transparent solid bisphenol fluorene type epoxy acrylate.

[0126] Next, 350 g of propylene glycol monomethyl ether acetate (PGMEA) was added and dissolved in 307.0 g of the obtained above-mentioned bisphenol fluorene type...

Embodiment 2~5、 comparative example 1~5

[0136] Except that in Example 1, the compounding amounts of (A), (B), (C), and (D) components represented in Table 1 and Table 2 were prepared, the rest were prepared in the same manner as in Example 1. Colored photosensitive resin combination. Each component described in Table 1 and Table 2 is as follows.

[0137] [Synthesis of compound (B-2)]

[0138] 35g glycidyl methacrylate, 100g fluoromonomer (CH 2 =C(CH 3 ) COOCH 2 CH 2 (CF 2 ) 6 F), 45g methyl methacrylate, 7g chain transfer agent n-dodecyl mercaptan, 2g 2,2'-azobis (4-methoxy-2,4-dimethylvaleronitrile) dissolved in 600 g of cyclopentanone was stirred and polymerized at 60° C. in a nitrogen atmosphere to obtain a solution of a copolymer.

[0139] Add 8 g of acrylic acid and 140 mg of triphenylphosphine to the solution of the above copolymer, dissolve and stir at about 100 to 120°C to react the epoxy group derived from glycidyl methacrylate in the above copolymer with the carboxyl group of acrylic acid . At th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com