Open type software numerical control system

A numerical control system, an open technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of strong specificity, operation dependence, non-expandability, etc., and achieve good versatility, scalability, and portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

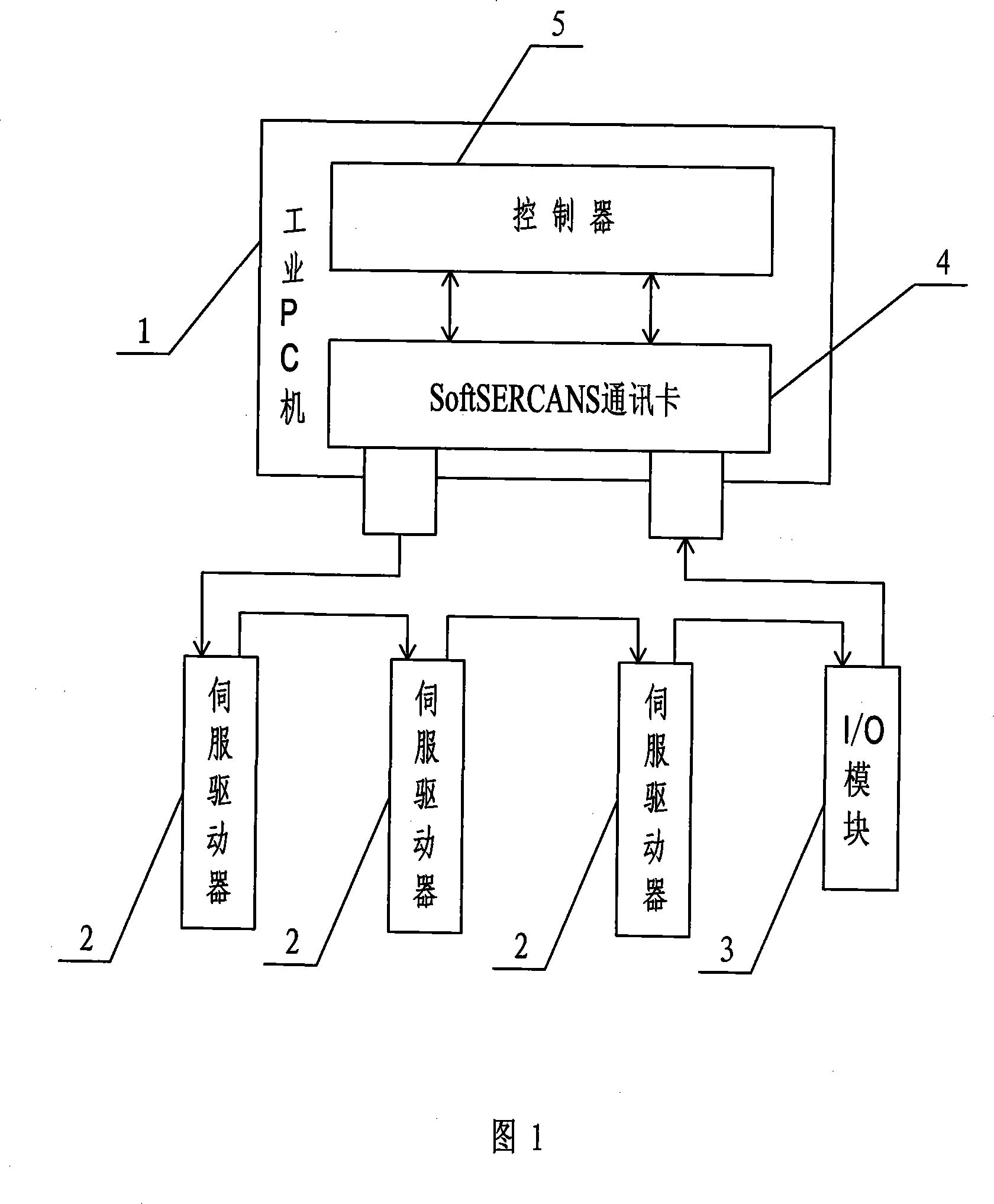

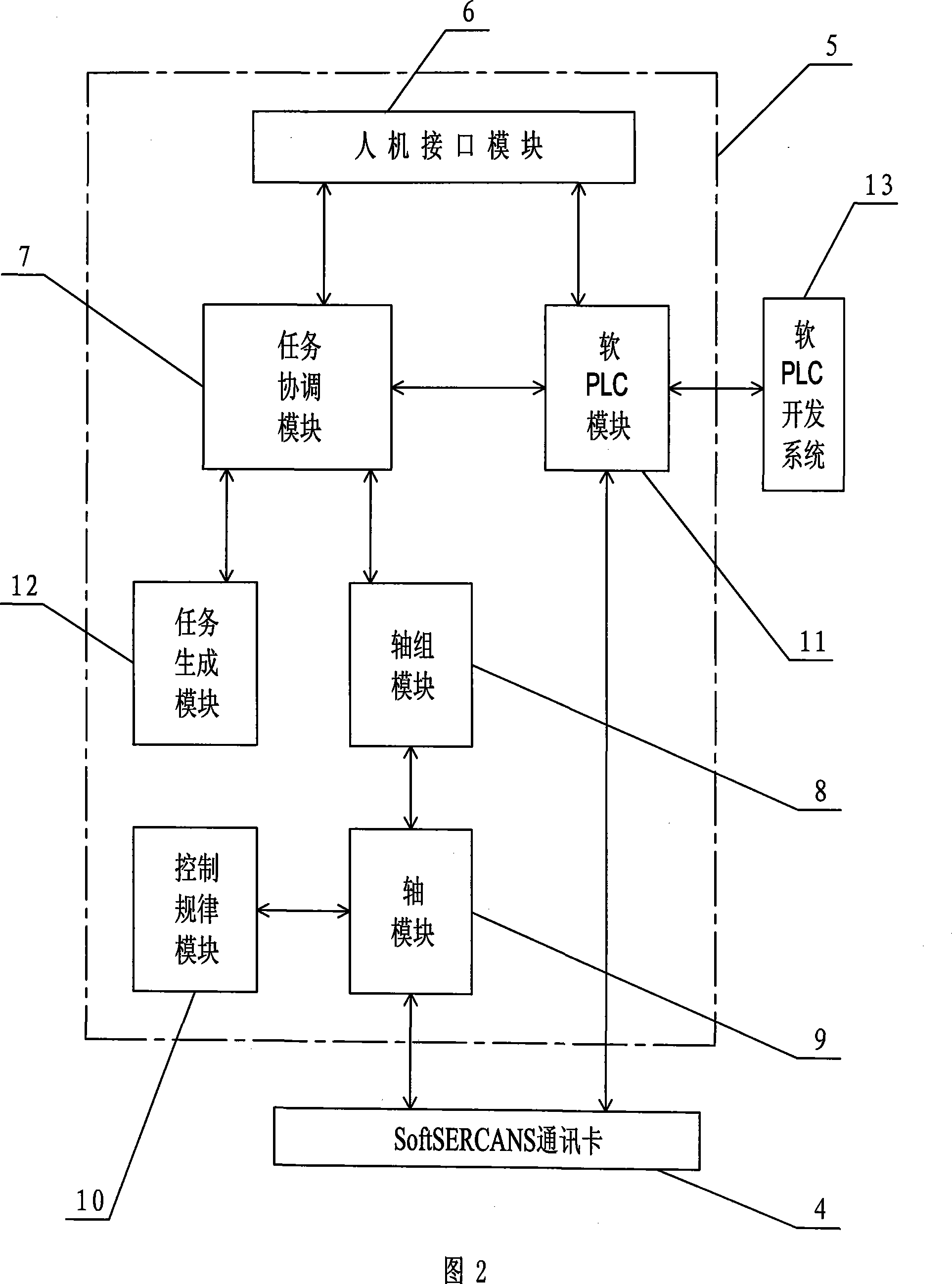

[0012] Specific embodiment one: referring to Fig. 1, Fig. 2, this embodiment consists of an industrial PC 1 based on the Windows operating system expanded in real time by RTX, a servo drive 2 and an I / O module 3 conforming to the SERCOS international agreement standard, conforming to the SERCOS international agreement The standard SoftSERCANS communication card 4 used to complete the communication between the controller 5, the servo drive 2 and the I / O module 3, and the controller 5 used to realize the servo control function and the switch control function;

[0013] Controller 5 consists of the following units:

[0014] Man-machine interface module 6, modify and set the parameters of task coordination module 7, edit PLC program, display diagnostic information and PLC feedback information;

[0015] The task coordination module 7 distributes tasks from the man-machine interface module 6 and the soft PLC module 11 to the axis group module 8;

[0016] The axis group module 8 acce...

specific Embodiment approach 2

[0021] Specific implementation mode 2: The difference between this implementation mode and specific implementation mode 1 is that based on the numerical control software package, an open numerical control system applied to five-axis linkage milling machines is established, which supports linear and spline processing and other numerical control functions, and uses software servo The method realizes position loop and speed loop control. Its software platform is: RTX real-time expansion adopts RTX6.5.1 of American Venturcom Company, Windows operating system adopts Windows XP SP2; hardware platform is: Industrial PC 1 adopts AXIOMTEK workstation with CPU as PentiumIV3.0GHz and memory as 1GB , the SoftSERCANS communication card 4 adopts the communication card connected with the PC 1 through the PCI bus, and is connected with the peripheral equipment through the SERCOS optical fiber ring; There are SERCOS interface input and output modules and the matrix encrypted CNC panel of Saiya...

specific Embodiment approach 3

[0022] Specific embodiment three: referring to Fig. 2, present embodiment has increased following unit on the basis of specific embodiment one: task generation module 12, carries out grammar and lexical check to the numerical control machining program from task coordination module 7, separates and extracts processing program The information in it generates motion segment instructions and logic control instructions containing motion information, and completes tool compensation at the same time, and feeds back the results to the task coordination module 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com