Method for quantitative analysis of bicomponent fibre textile

A two-component fiber, quantitative analysis technology, applied in the field of textile inspection, can solve the problems of narrowing the application range, affecting the dissolution efficiency, deteriorating the working environment, etc., and achieve the effect of enhancing the anti-solution ability, broad application prospects, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

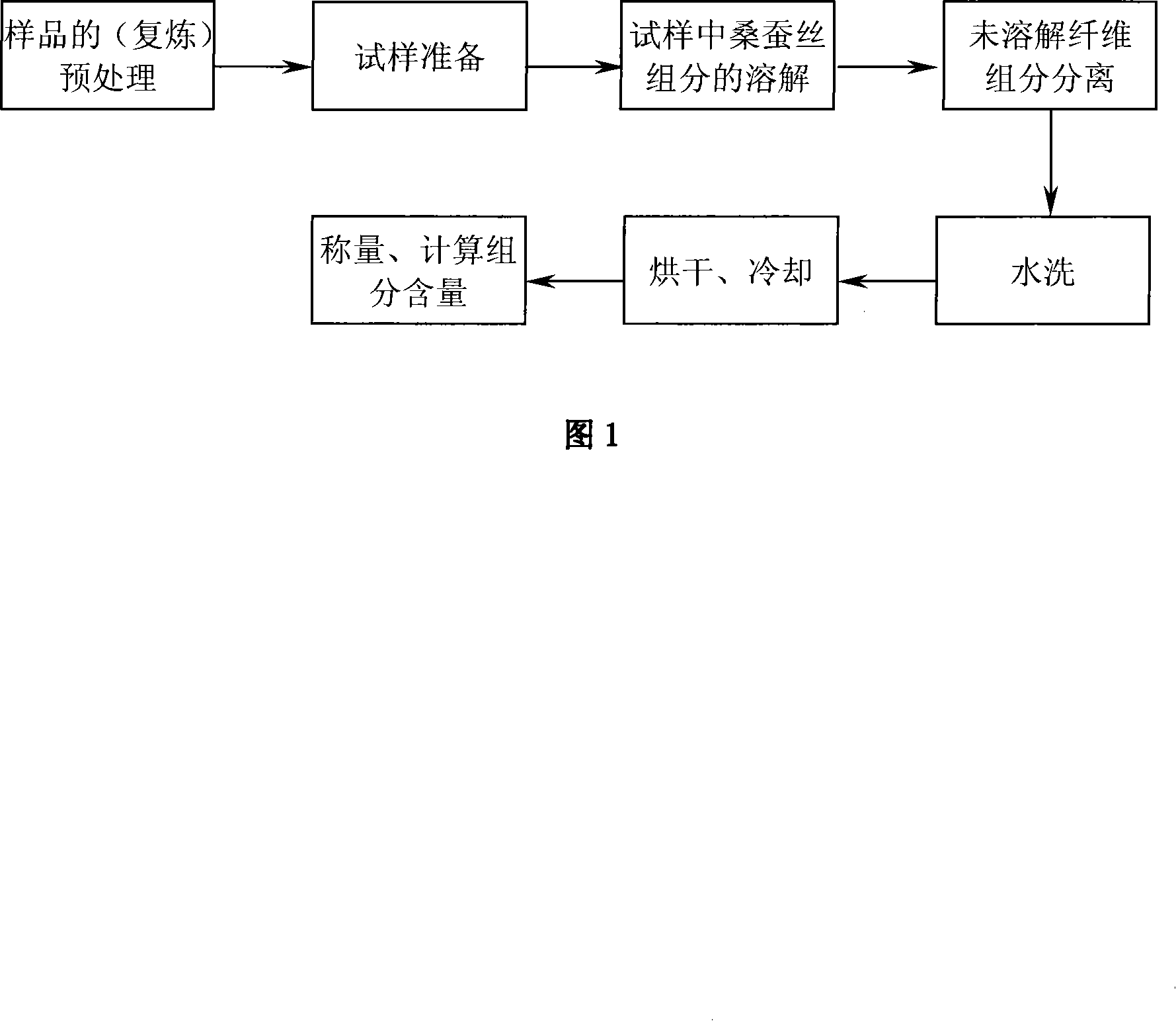

[0017] The sample that the required quantitative analysis inspection of present embodiment is through qualitative analysis is the mixed silk cotton sample of the different proportions of mulberry silk (Jiangsu Hai'an) and tussah silk (Liaoning), it is carried out quantitative analysis inspection, referring to accompanying drawing 1, by this implementation As can be seen in the flow chart of the quantitative analysis method of the two-component fiber textile containing mulberry silk, its concrete steps are as follows:

[0018] (1) Sample pretreatment (recombination)

[0019] The purpose of sample pretreatment (refining) is to remove the ash, grease and residual sericin on the silk cotton. Cut about 5.0g of the qualitatively analyzed sample, put it into a beaker, and add 2.0g of L -1 Anhydrous sodium carbonate and 4.0gL -1 Synthetic detergent solution, bath ratio is 1:80. Heat to 95°C in a constant temperature water bath, stir once every 10 minutes, and keep warm for 1 hour. ...

Embodiment 2

[0032] In this example, a commercial mulberry silk / nylon two-component blended fabric is used, and the specific steps and other conditions of its quantitative analysis are as described in Example 1.

[0033] Table 2 is the result of the quantitative analysis test of the mulberry silk / nylon two-component blended fabric in Example 2.

[0034] Table 2

[0035]

[0036] The test results in Table 2 show that the nylon component has good solubility resistance in the solution, and its fiber mass loss rate is low. The measured value is in good agreement with the theoretical value, and the reliability is high. The method overcomes the disadvantage of weak solvent resistance of the nylon component in the traditional calcium chloride alcohol solution, and expands the scope of application of the method, so it can be widely used in the quantitative analysis and testing of mulberry silk / nylon textiles.

Embodiment 3

[0038] In this example, a commercial mulberry silk / wool two-component blended fabric is used, and the specific steps and other conditions of its quantitative analysis are as described in Example 1.

[0039] Table 3 is the result of the quantitative analysis test of embodiment three pair of mulberry silk / wool two-component blended fabrics.

[0040] table 3

[0041]

sample

Mass before dissolution (g)

dissolved matter

amount (g)

wool fiber quality

Loss rate (%)

Wool fiber content (%)

theoretical value

measured value

wool /

Mulberry silk

0.1473 / 0.9013

0.3330 / 0.7884

0.7262 / 0.3309

0.1465

0.3312

0.7221

0.54

0.54

0.56

14.05

29.70

68.70

13.97

29.53

68.31

[0042] Table 3 shows that the present invention also obtains better quantitative analysis effect on mulberry silk / wool two-component b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com