Optical compensation film, preparation method thereof, polarizer and liquid crystal display device

An optical compensation film, optical technology, applied in chemical instruments and methods, optics, polarizing elements, etc., can solve the problems of poor working performance of polarizers, light leakage, narrowing of the viewing angle, etc., and achieve the effect of expanding the viewing angle and reducing the color shift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

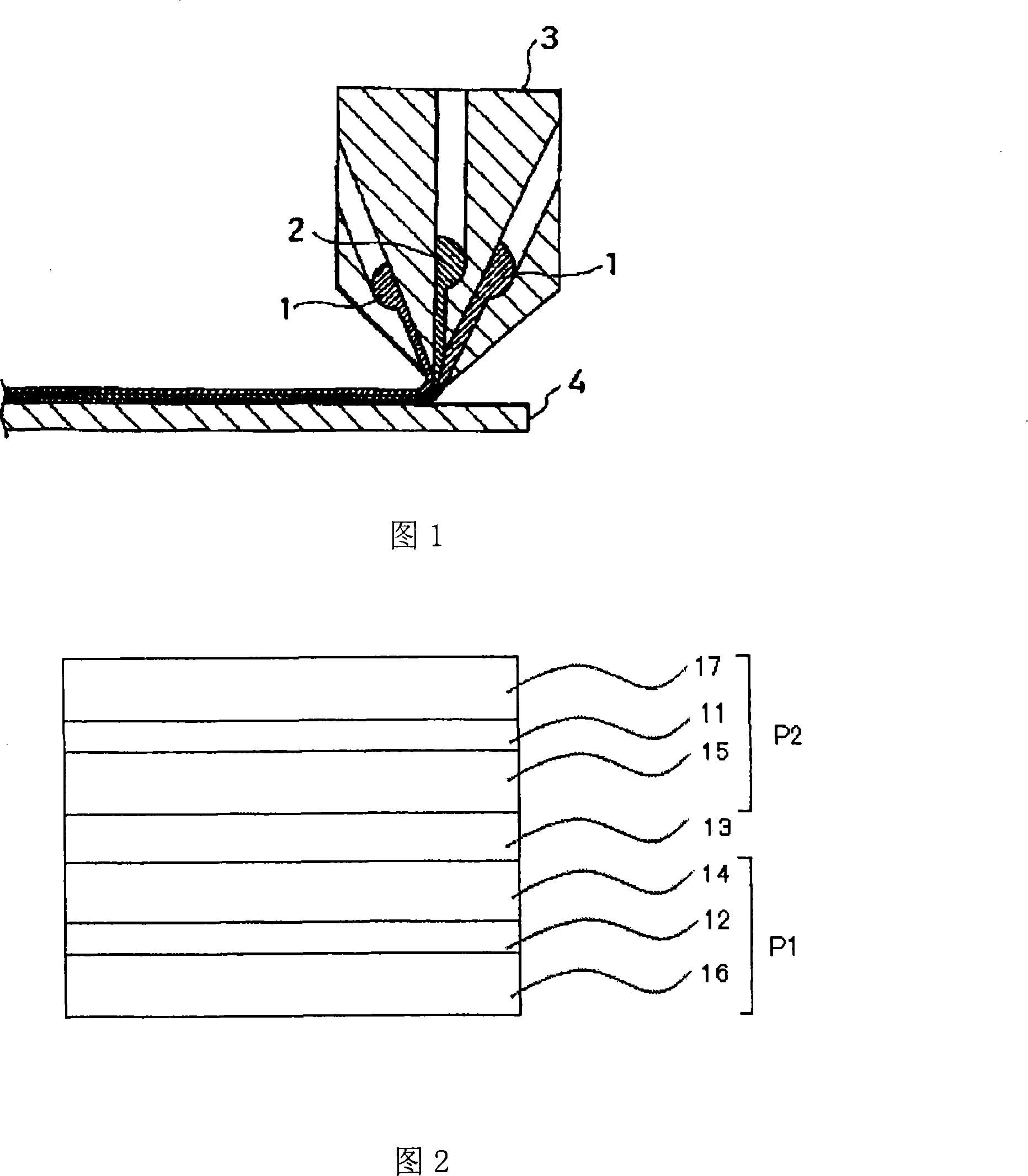

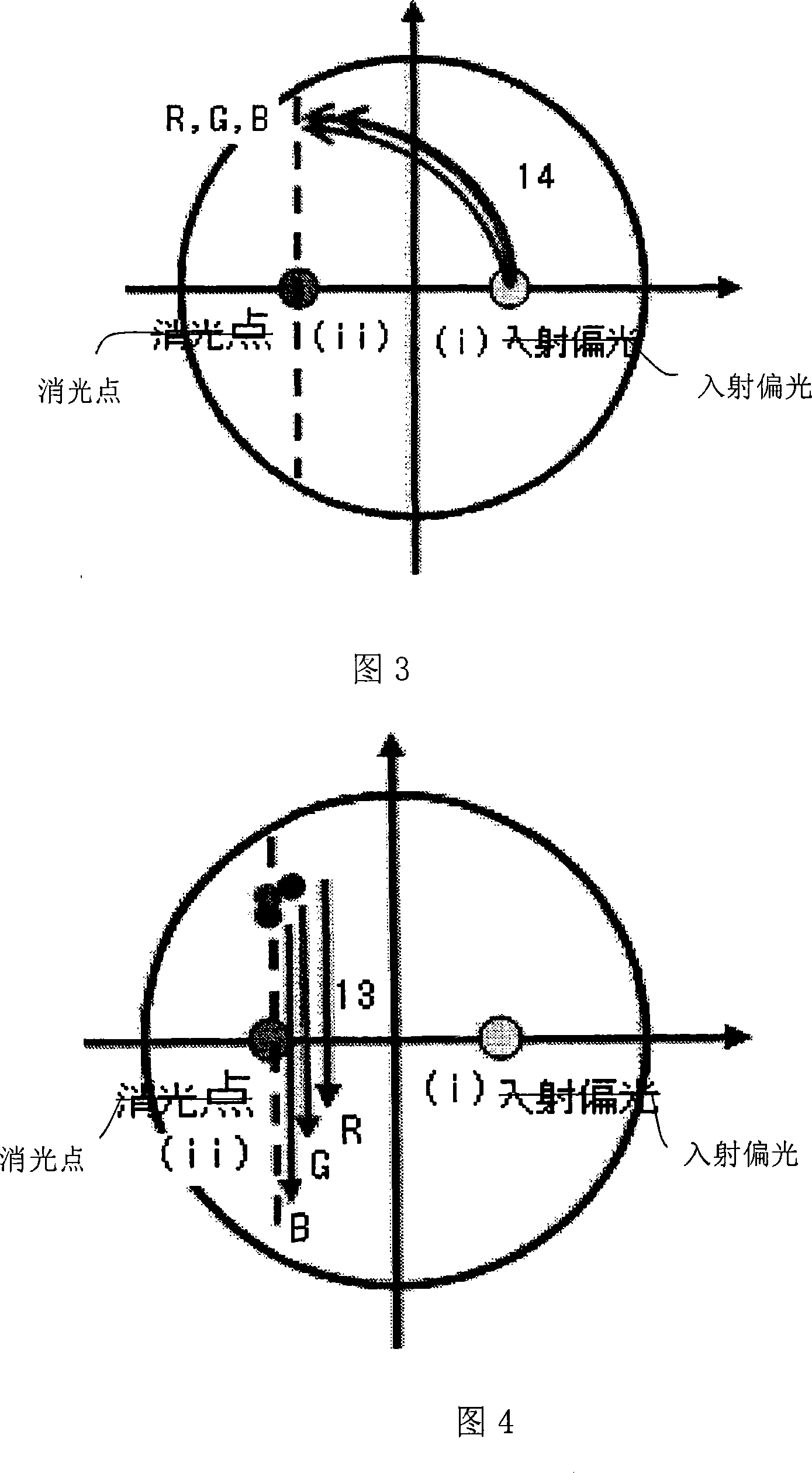

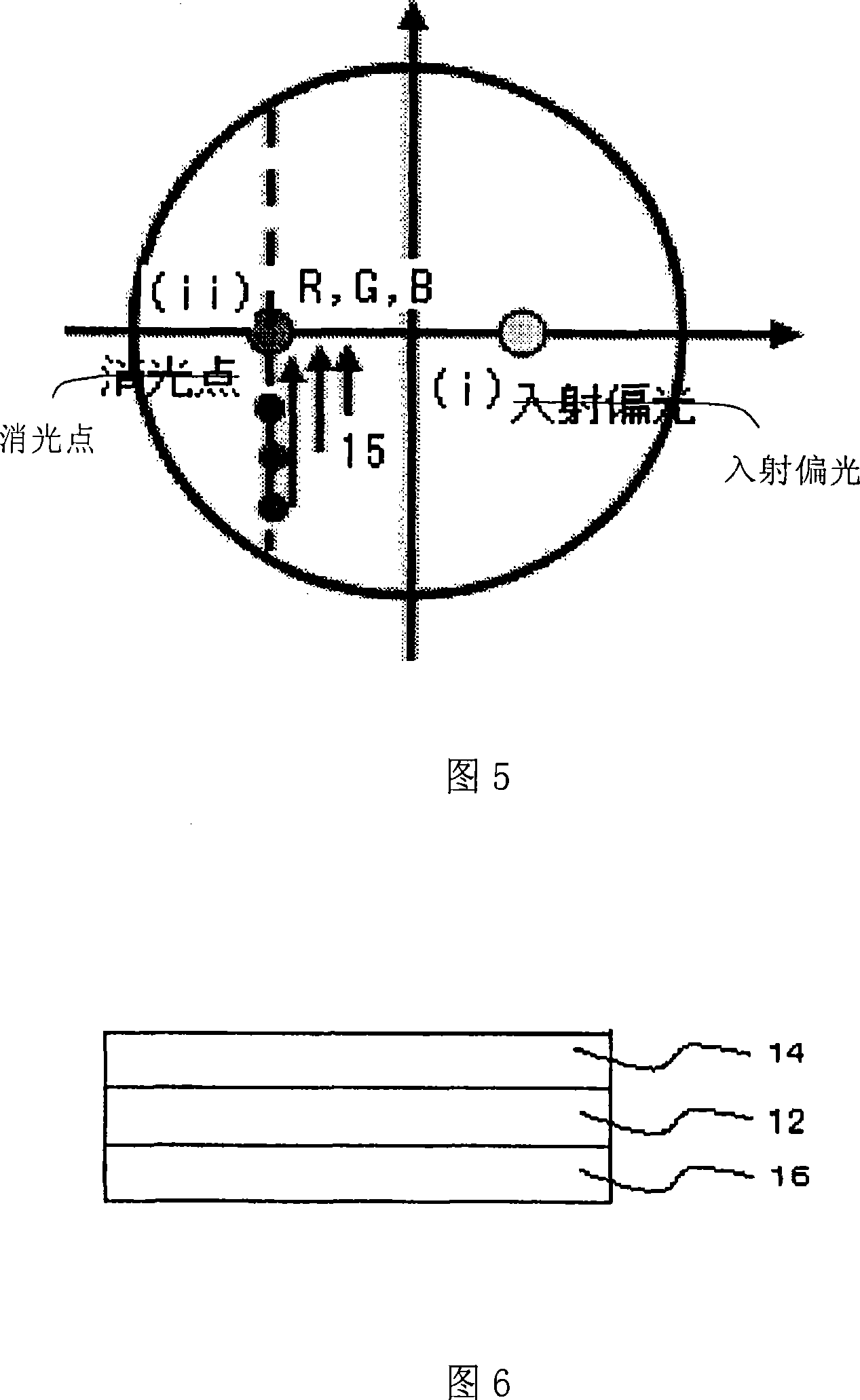

Method used

Image

Examples

preparation example Construction

[0212] In general, examples of drying the dope on a metal support according to the production of cellulose acylate film include a method of blowing hot air from the surface side of the metal support (drum or belt) (i.e., from the film sheet (web) side on the metal support) ; the method of blowing hot air from the back of the cylinder or belt; and the method of controlling the surface temperature by contacting the temperature control liquid with the back of the belt or cylinder (the surface opposite to the dope casting surface) and heating the cylinder or belt due to heat conduction Backside liquid heat conduction method. Among these methods, the back liquid heat conduction method is preferable. The surface temperature of the metal support before casting may be arbitrary as long as it is not higher than the boiling point of the solvent used in the dope. However, in order to accelerate drying or reduce fluidity on the metal support, it is preferable that the surface temperature o...

Embodiment 1

[0339] Preparation of Cellulose Acylate Film Sample 102

[0340] (Preparation of cellulose acetate solution 102)

[0341] A cellulose acetate solution was prepared by pouring the following composition into a mixing tank and stirring to dissolve the components.

[0342] Cellulose acetate (degree of substitution: 2.86): 100.0 parts by mass

[0343] ●Triphenyl phosphate: 6.3 parts by mass

[0344] ●Diphenyl phosphate: 5.0 parts by mass

[0345] ●Dichloromethane: 366.5 parts by mass

[0346] Methanol: 54.8 parts by mass

[0347] (Preparation of Matting Agent Dispersion 102)

[0348] The following composition was put into a disperser and stirred to dissolve the components, thereby preparing a matting agent solution.

[0349] ●Silicon dioxide particles with an average particle size of 20 nm (AEROSIL 2.0 parts by mass

[0350] R972, manufactured by Nippon Aerosil Co. Ltd.):

[0351] ●Dichloromethane: 76.3 parts by mass

[0352] Methanol: 11.4 parts by mass

[0353] ●Cellu...

Embodiment 2

[0367] Preparation of Cellulose Acylate Film Sample 103

[0368] (Preparation of additive solution 103)

[0369] Additive solutions were prepared by pouring the following compositions into a mixing tank and stirring to dissolve the components.

[0370] ●Illustrative compound (104): 10.0 parts by mass

[0371] ●Dichloromethane: 36.8 parts by mass

[0372] Methanol: 5.5 parts by mass

[0373] ●Cellulose acetate solution 101: 12.8 parts by mass

[0374] (processing)

[0375] The aforementioned cellulose acetate solution and the additive solution were mixed in the following proportions to prepare a dope for processing. The same dope as that of sample 102 was used as the dope of the surface layer.

[0376] (Preparation of dope 103 for processing)

[0377] The following composition was put into a mixing tank and stirred, and each component was adjusted to have a ratio described later and mixed and dissolved, thereby preparing a dope for processing.

[0378] ●Cellulose acet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com