Non-mask write through photo-etching machine with ultrahigh strength LED light source

An LED light source and ultra-high-intensity technology, which can be used in micro-lithography exposure equipment, photo-plate-making process exposure devices, etc., can solve problems such as insufficient energy of light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

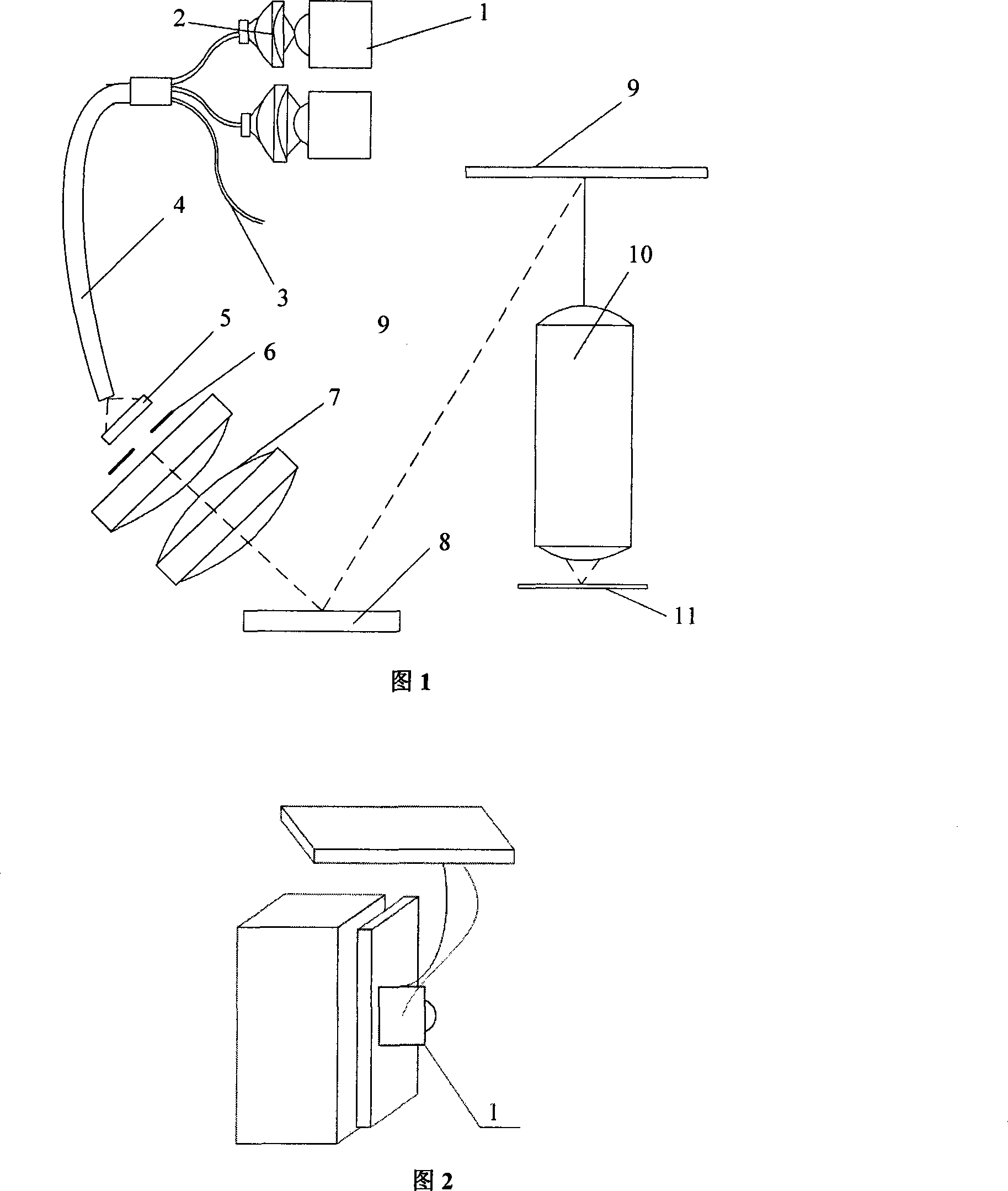

[0027] A maskless direct writing lithography machine with an ultra-high-intensity LED light source includes a light source, an aperture stop 6, a relay objective lens 7, a mirror 8, a digital mask plate 9, a projection objective lens 10, and a wafer table 11; the light source is a light emitting The diode light source, the light source aperture diaphragm 6 and the relay objective lens 7 are located on the same axis, and correspond to the mirror 8, and the mirror 8 corresponds to the DMD digital mask 9 on one side, and the DMD digital mask 9 passes through the projection below it The objective lens 10 corresponds to the wafer surface 11 .

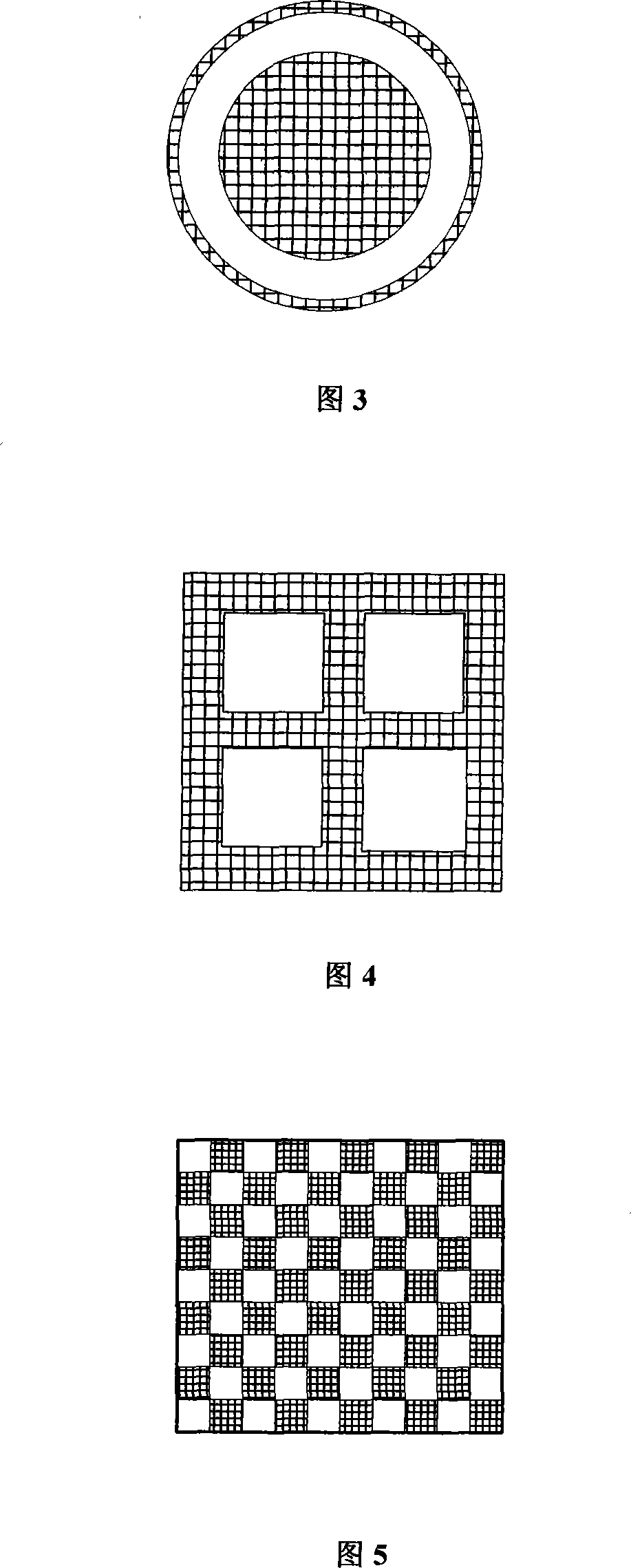

[0028] The light source includes two light-emitting diodes 1; each light-emitting diode corresponds to a condenser lens 2, and the rear of each condenser lens 2 is respectively connected to a coupling fiber 3, and the coupling fiber 3 is connected to a core-changing fiber 4, and the core-changing fiber 4 The other end corresponds to the cohe...

Embodiment 2

[0033] The light source includes three light emitting diodes 1;

[0034] The coherent plate 5 is a quadrupole illuminated coherent plate, as shown in FIG. 4 .

[0035] Other structures are with embodiment 1.

Embodiment 3

[0037] The light source includes four light emitting diodes 1;

[0038] The coherent film 5 is a binary grating illumination coherent film, as shown in FIG. 5 .

[0039] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com