Method for treating and reclaiming waste water of 2-aminopyridine production

An aminopyridine, a technology for producing wastewater, which is applied in water/sewage treatment, natural water treatment, chemical instruments and methods, etc., and can solve the problems of waste of resources, strong corrosiveness and high toxicity of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

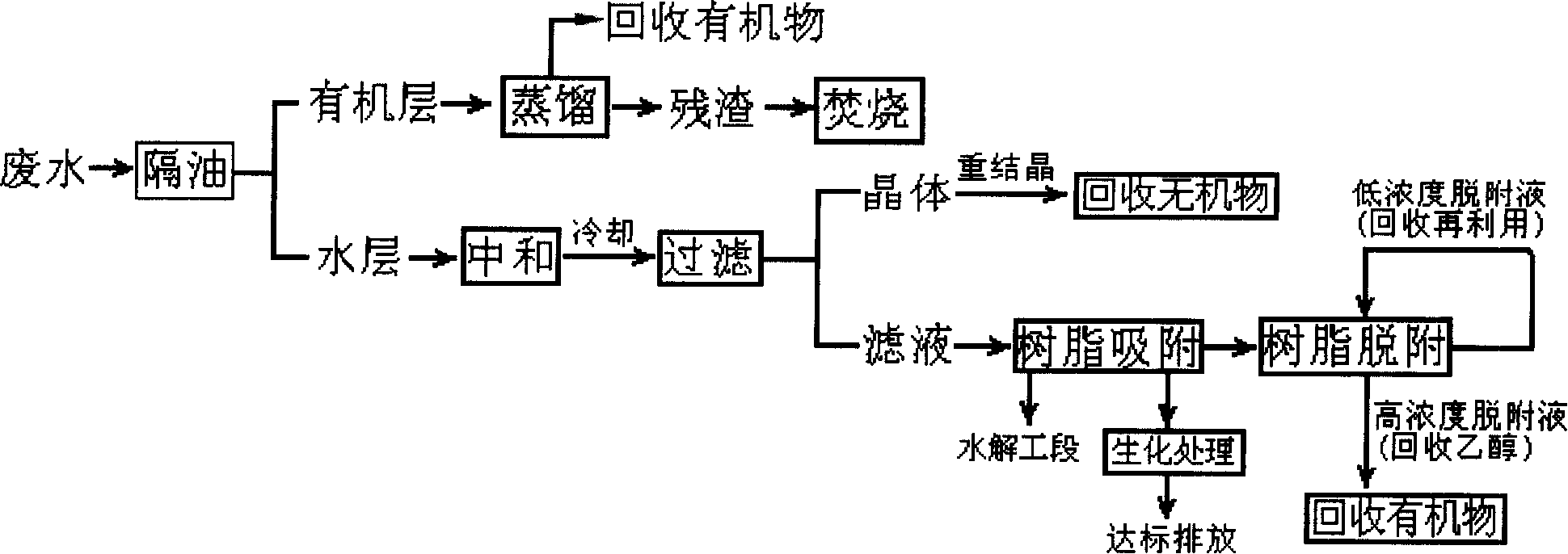

[0019] 1. Oil separation: The waste water produced by the hydrolysis reaction is separated from the organic layer through the oil separation tank, and the 2-aminopyridine is recovered by vacuum distillation, and the residue is incinerated.

[0020] 2. Neutralization: the water layer was adjusted to a pH close to neutral with dilute sulfuric acid, crystallized by cooling, and filtered under reduced pressure. The obtained crude product is purified by recrystallization method, and the inorganic salt is recovered. The filtrate is light yellow, pH 7-8, density 1.26, color 50 times, COD Cr About 3600mg / L.

[0021] 3. Resin pretreatment: Accurately weigh 2.000g of NDA-150 ultra-high cross-linked adsorption resin, place it in a small measuring cylinder, soak it in methanol for 2 hours, read the volume (BV) of the wet resin, pour out the methanol, and wash it with pure water until No alcohol smell, transfer the resin to the exchange column to drive away the air bubbles in the resin l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com