Swelling pre-squeezing leaching preparation method for high oil-containing material

A technology of leaching and oilseeds, applied in the direction of fat oil/fat production, fat production, etc., to achieve the effect of easy operation, good percolation, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

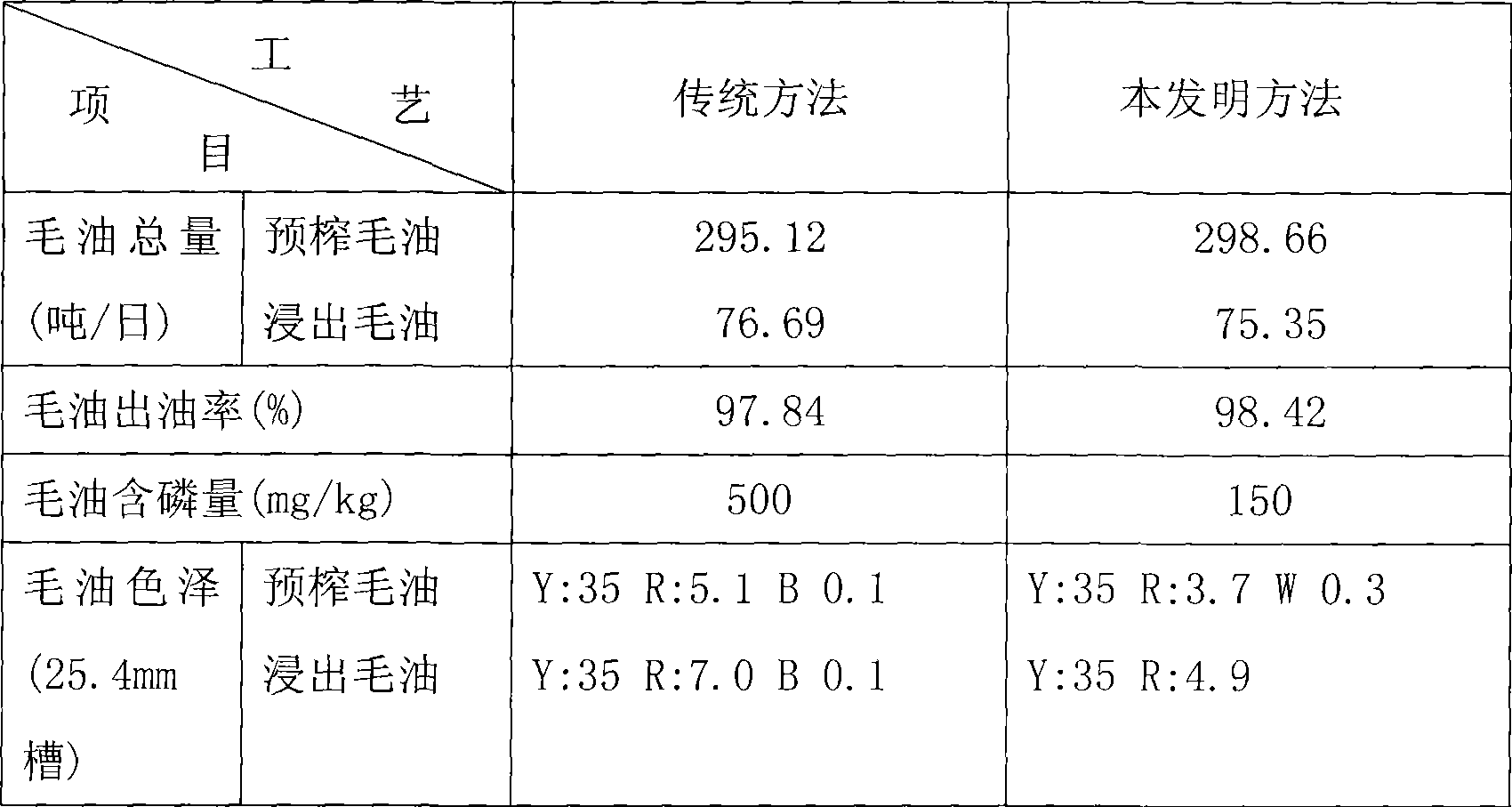

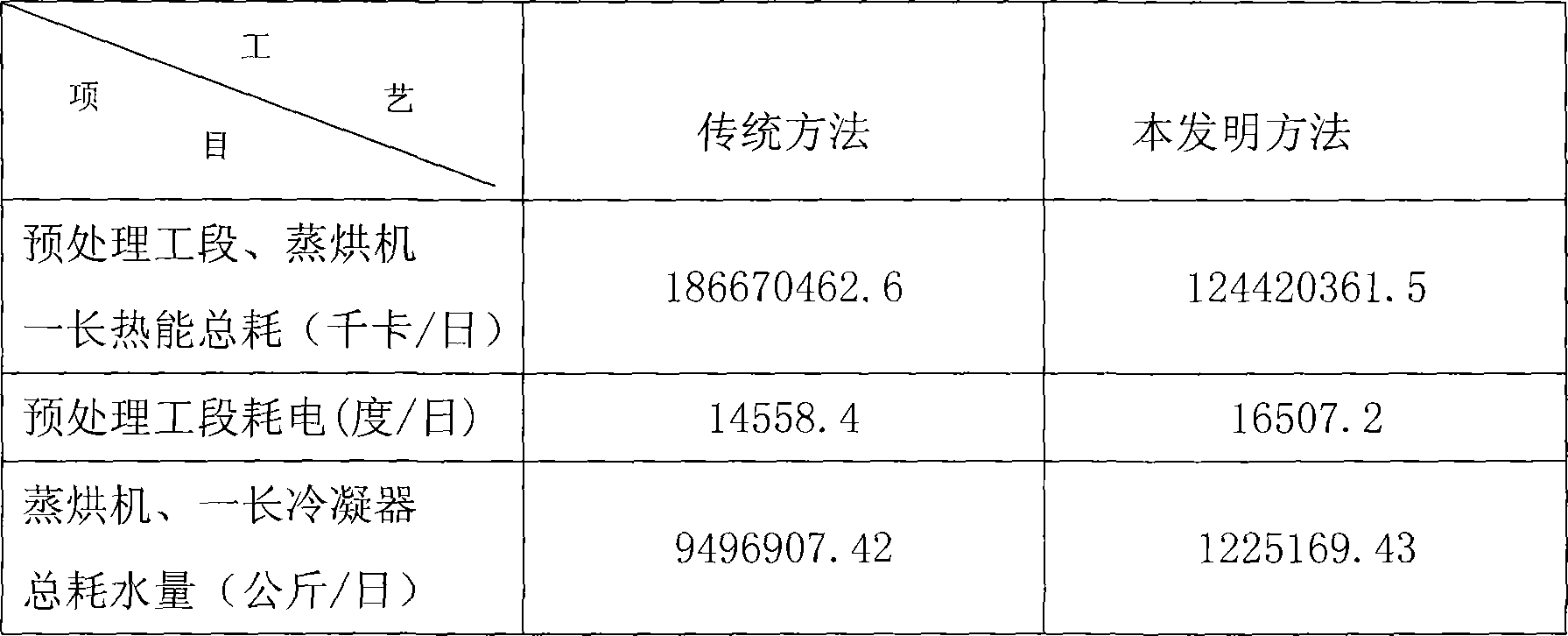

Embodiment 1

[0046] Embodiment 1: domestic rapeseed is processed according to the inventive method, and steps are as follows successively:

[0047] 1. Cleaning: After the rapeseed is screened by a plane rotary sieve, a stone remover, a magnetic separator, and winnowed, the impurity content is 0.4%;

[0048] 2. Tempering: after moisture adjustment at 55°C, the moisture content is 10%;

[0049] 3. Billet rolling: the thickness of the billet is 0.4mm;

[0050] 4. Extrusion and puffing: It is carried out on an oil extrusion puffing machine, the steam pressure is 0.6Mpa, the puffing outlet temperature is 90°C, the puffing coefficient is 1.25, the moisture content of the flakes entering the puffing machine is 10%, and the puffing material moisture content of the puffing machine is 12%. ;

[0051] 5. Drying: the moisture content of the extruded material after drying is 4%;

[0052] 6. Pre-pressing: Use a pre-pressing machine to pre-press the dried puffed material. When entering the press, the ...

Embodiment 2

[0054] Embodiment 2: Imported rapeseed is processed according to the method of the present invention, and the steps are as follows:

[0055] 1. Cleaning: After the rapeseed is screened by plane rotary sieve, de-stoner, magnetic separator, and winnowing, the impurity content is 0.3%;

[0056] 2. Tempering: the moisture content of imported rapeseed is less than 7%, and the moisture is 9% after softening with water at 50°C;

[0057] 3. Billet rolling: the thickness of the billet is 0.3mm;

[0058] 4. Expansion: steam pressure 0.7Mpa, puffing outlet temperature 95°C, expansion coefficient 1.30, moisture content of the flakes entering the extruder is 9%, moisture content of the puffed material exiting the extruder is 11%;

[0059] 5. Drying: the moisture content of the extruded material after drying is 5%;

[0060] 6. Pre-pressing: Use a pre-pressing machine to pre-press the dried puffed material, with 5% moisture, 100°C temperature, and 13% residual oil in the pre-pressed cake. ...

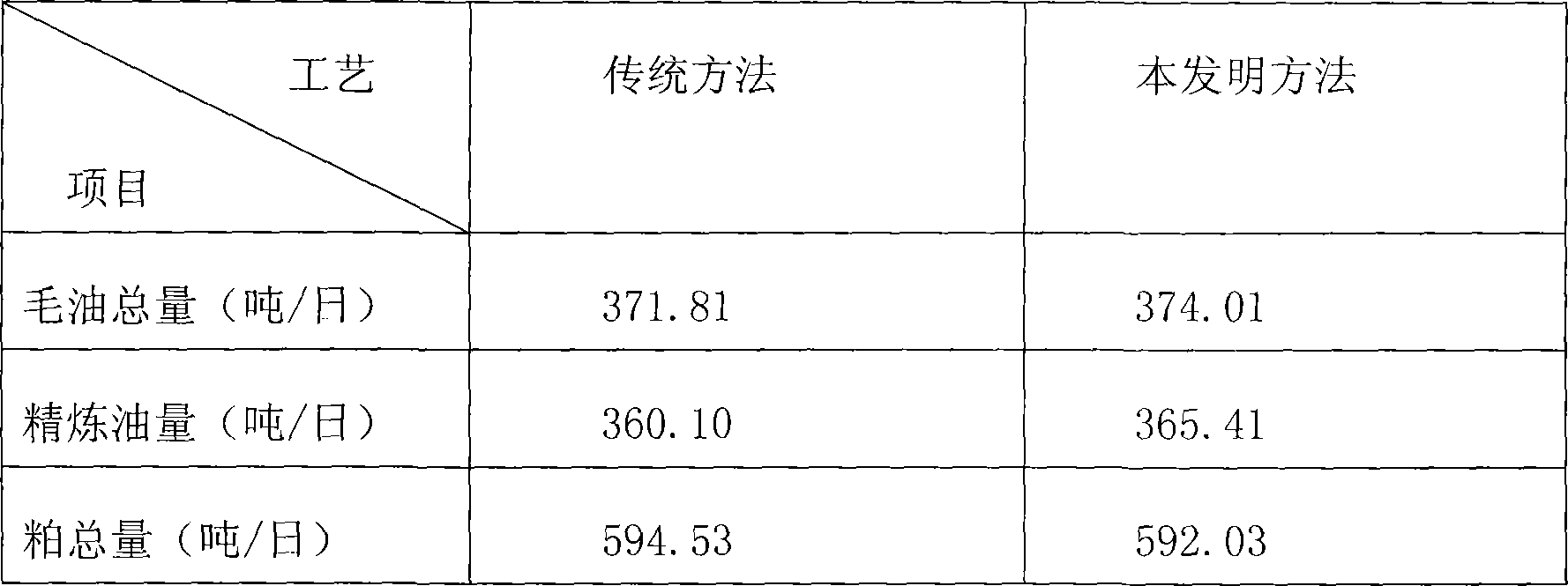

Embodiment 3

[0062] Embodiment 3: Cottonseed kernels are processed according to the method of the present invention, and the steps are as follows:

[0063] 1. Cleaning: After the cottonseed after delinting is first cleaned and screened, stoner removed, magnetic separator, shelled, and kernel shell separated, the impurity content is 0.3%;

[0064] 2. Tempering: After adding water at 55°C to soften, the water content is 10%;

[0065] 3. Billet rolling: the thickness of the billet is 0.3mm;

[0066] 4. Extrusion and puffing: It is carried out on an oil extrusion puffing machine with a steam pressure of 0.7Mpa, an puffing outlet temperature of 105°C, and an expansion coefficient of 1.30; %;

[0067] 5. Drying: the moisture content of the extruded material after drying is 5%;

[0068] 6. Pre-pressing: Use a pre-pressing machine to pre-press the dried puffed material. When entering the press, the moisture content of the puffed material is 5%, and the temperature of entering the press is 105°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com