Method for preparing microbial oil and fat

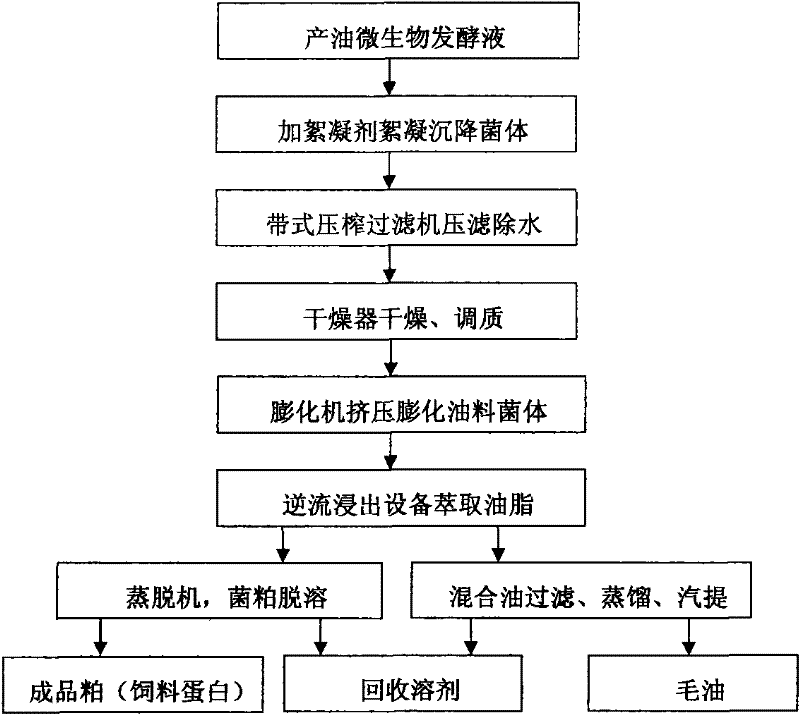

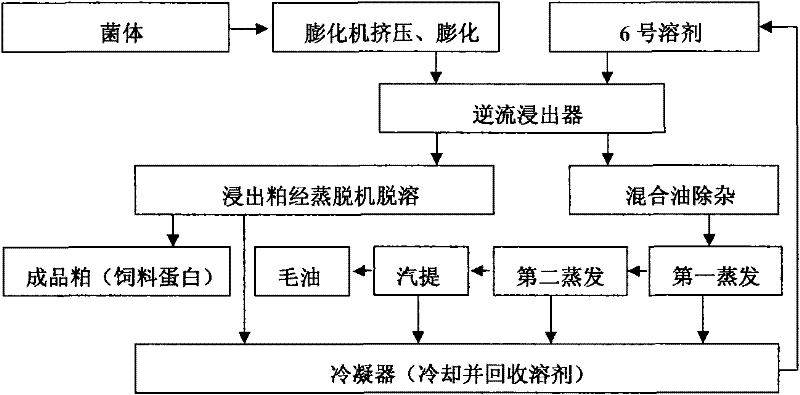

A technology of microbial oil and microbial bacteria, applied in the production of fat, fat oil/fat production, fermentation, etc., can solve the problems of small batch batch, long extraction time, long process route, etc., to reduce labor consumption and power consumption, The effect of reducing steaming and preheating and improving the quality of crude oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 5m after fermentation of Rhodotorula oleaginousis 3 Fermented liquid is processed according to the inventive method, and steps are as follows successively:

[0050] (1) Flocculation, add pre-prepared 0.2wt‰ polyacrylamide aqueous solution to the fermentation broth in an amount of 40ppm, the flocculation reaction time is 10min, the precipitation time is 30min, the water removal rate reaches 67%, and the dry cell content is 3wt % increased to 9 wt%.

[0051] (2) Pressure filtration, the flocculation thallus is sent to the belt press filter, and under 2.5 atmospheres, through gravity concentration dehydration, wedge-shaped pre-press dehydration and roller press dehydration for 20min, the water content of the filter cake (taken as dry thallus) is obtained. The weight is on a dry basis) is 73 wt%. The dry cell content is 27wt%.

[0052] (3) Conditioning: In the chain-type flat plate dryer, feed 120°C steam for drying and conditioning until the water content is reduced to ...

Embodiment 2

[0060] 10m fermented to Rhodotorula oleaginum 3 Fermented liquid is processed according to the inventive method, and steps are as follows successively:

[0061] (1) Flocculation, add a pre-prepared 0.5wt‰ polyacrylamide aqueous solution to the fermentation broth in an amount of 120ppm, the flocculation reaction time is 20min, the precipitation time is 1h, the water removal rate reaches 70%, and the dry cell content is 3wt % increased to 10 wt%.

[0062] (2) Pressure filtration, the flocculation thallus is sent to the belt press filter, and under 2 atmospheric pressures, through gravity concentration dehydration, wedge-shaped pre-press dehydration and roller press dehydration for 30min, the water content of the filter cake (taken as dry thallus) is obtained. The weight is based on dry basis) is 70wt%, and the content of dry cells is 30wt%.

[0063] (3) Conditioning, in the chain-type flat plate dryer, feed 125 DEG C of steam, carry out drying and tempering, the water content ...

Embodiment 3

[0070] 5 m after cultivation of Chlorella oleaginum 3 Fermented liquid is processed according to the inventive method, and steps are as follows successively:

[0071] (1) Flocculation, add pre-prepared 0.3wt‰ chitosan aqueous solution to the fermented liquid in an amount of 20ppm, stir at a low speed, the flocculation reaction time is 30min, and the settling time is 1.5h. The water rate reaches 96%, and the dry cell content of the algae increases from 0.3wt% to 7.5wt%.

[0072] (2) Pressure filtration, the flocculated thallus is sent to a belt press filter, and under 3 atmospheric pressures, through gravity concentration dehydration, wedge-shaped pre-press dehydration and roller press dehydration for 30min, the water content of the filter cake (taken as dry thallus) is obtained. The weight is based on dry basis) is 65wt%, and the content of dry cells is 35wt%.

[0073] (3) Conditioning, in the chain-type flat plate dryer, feed 125 DEG C of steam, carry out drying and temperi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com