Application of quinoline aluminum coordination macromolecule

A quinoline aluminum and polymer technology, applied in the field of luminescent materials, can solve problems such as limiting the feasibility of structural devices, and achieve low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

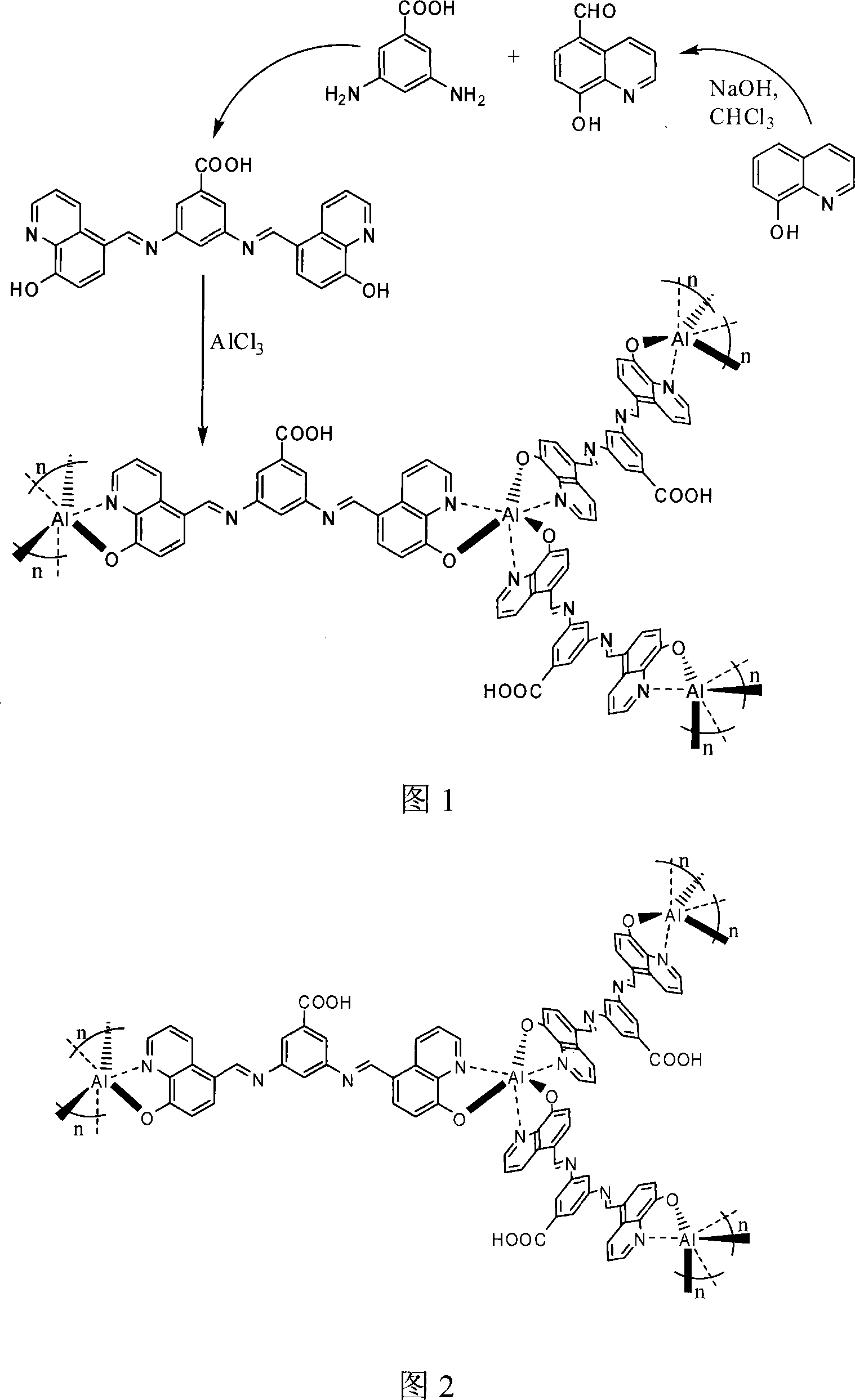

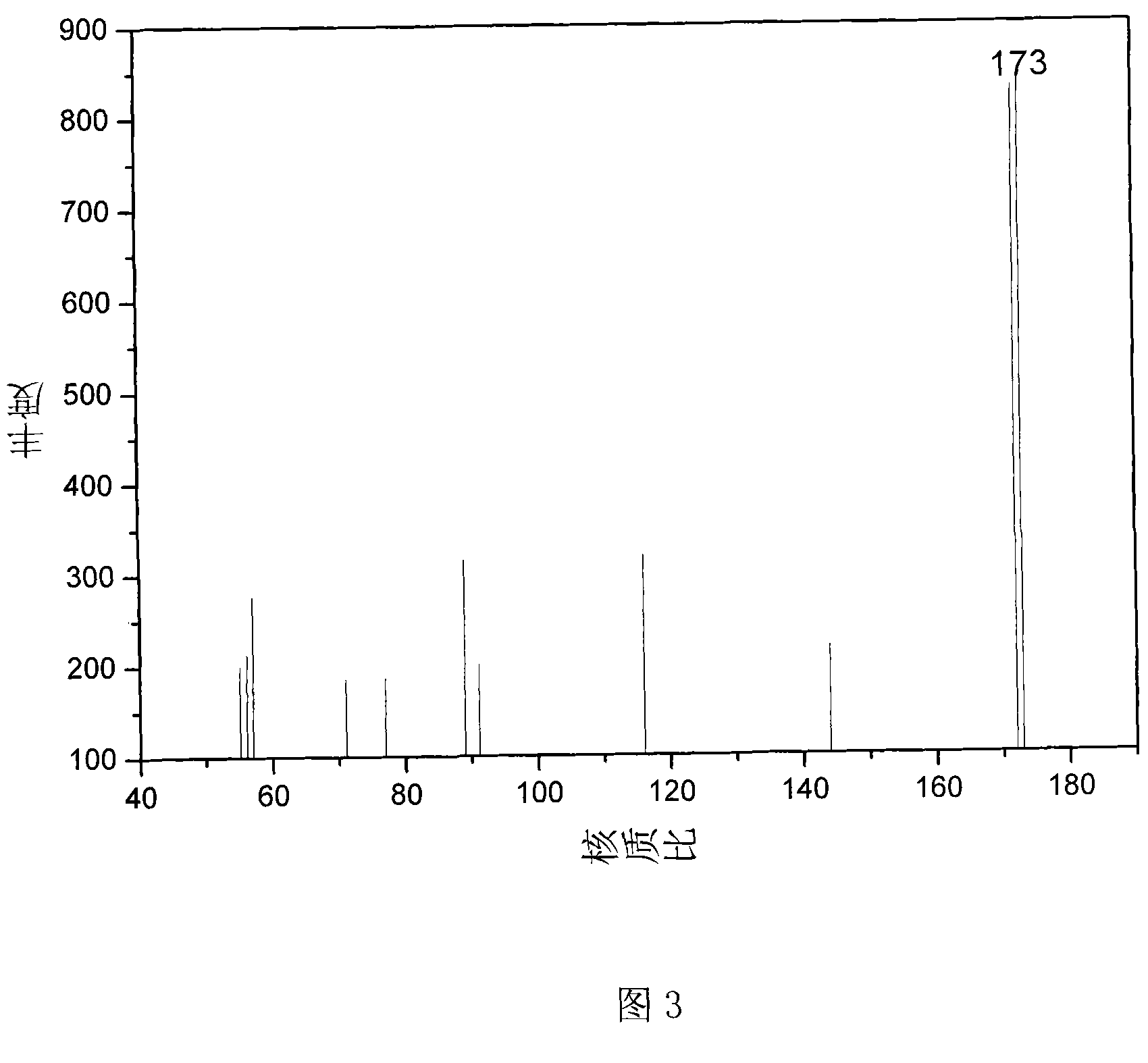

Method used

Image

Examples

Embodiment

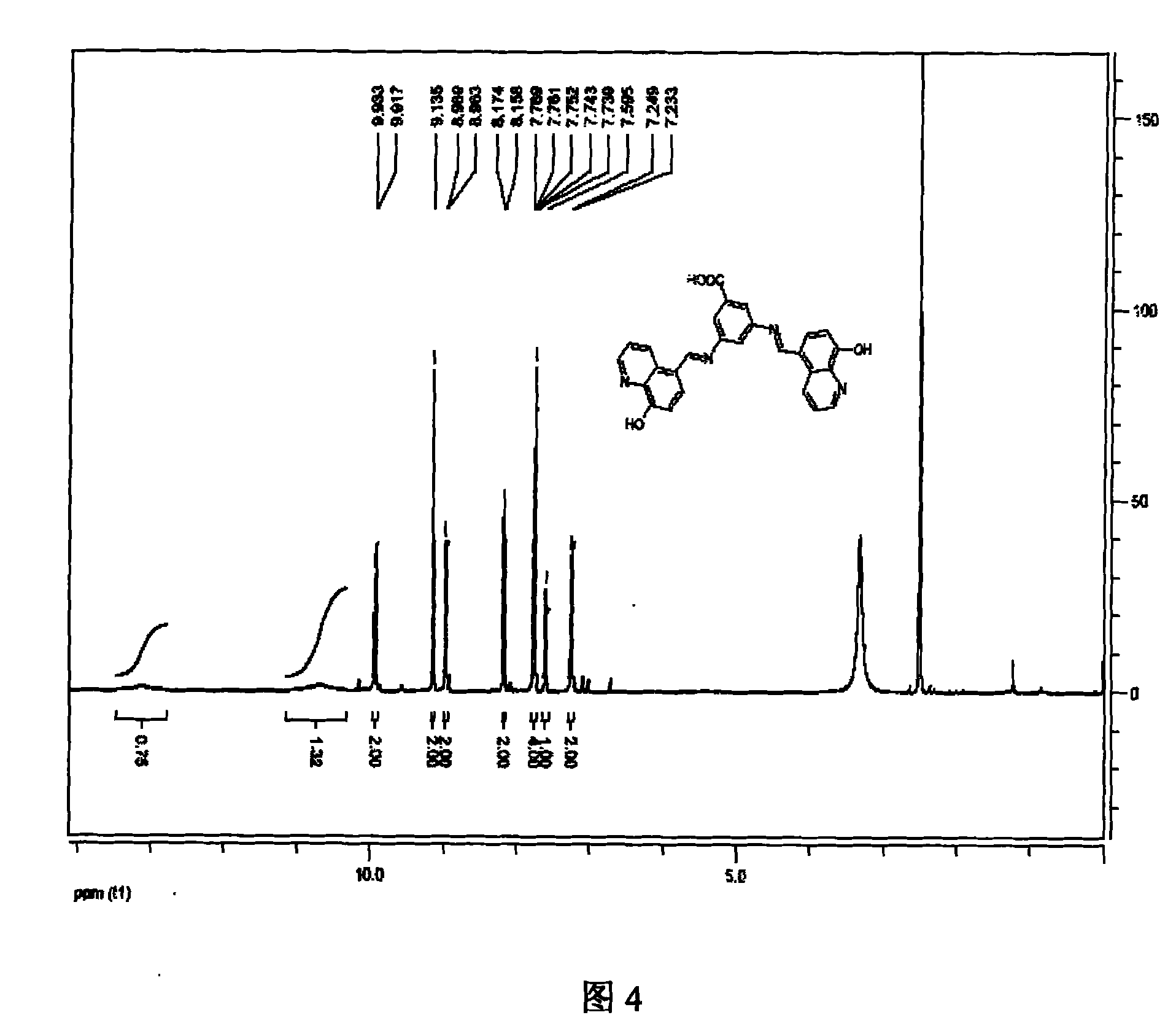

[0025] Dissolve 25 g of analytically pure 8-hydroxyquinoline in 100 mL of absolute ethanol, add NaOH solution (50 g of NaOH dissolved in 70 mL of deionized water), mix well and cool, then add dropwise chloroform (25 mL, drop over 1 hour). After the chloroform was added dropwise, the temperature was raised and stirred under reflux for 18 hours. Evaporate excess chloroform and ethanol on a rotary evaporator, dissolve the remaining residue in 600mL deionized water, adjust the pH value to 5-6 with dilute hydrochloric acid, a precipitate is formed, filter it with suction and wash it with deionized water, and remove the precipitate The material was dried in an oven at 80°C. Grind the dried solid into powder, extract with petroleum ether with a boiling range of 90-120°C for 48 hours in a fat extractor, cool the extract, collect the precipitate by filtration, and recrystallize with absolute ethanol. 5-Formyl-8-hydroxyquinoline is obtained. The results of mass spectrometry are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com