Method for preparing compact AlQ3 film

A thin-film and dense technology, which is applied in the field of preparing dense AlQ3 thin films, can solve the problems of reduced device life, low vacuum degree, and device failure, and achieve stable electrical properties, good compactness, and consistent crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

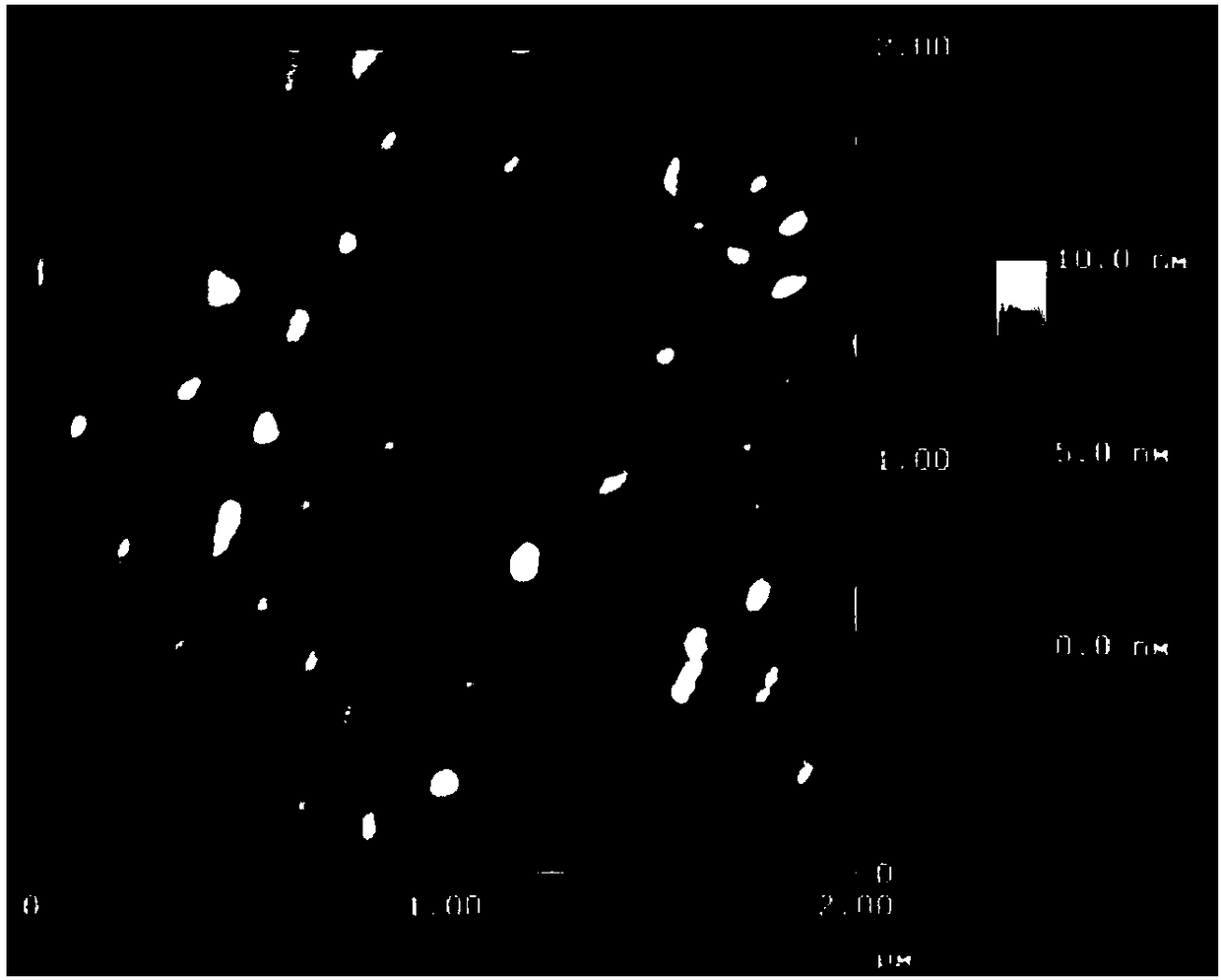

Examples

Embodiment 1

[0025] A preparation of dense AlQ 3 A thin film method comprising the steps of:

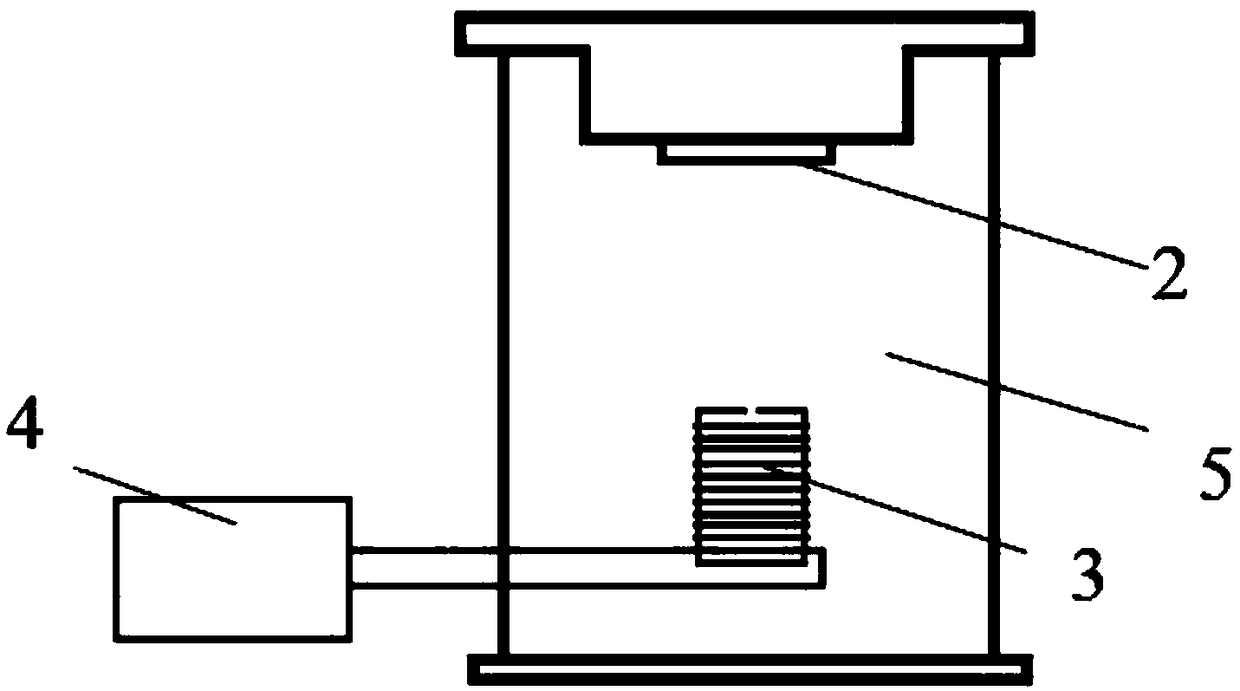

[0026] Step 1, build the device

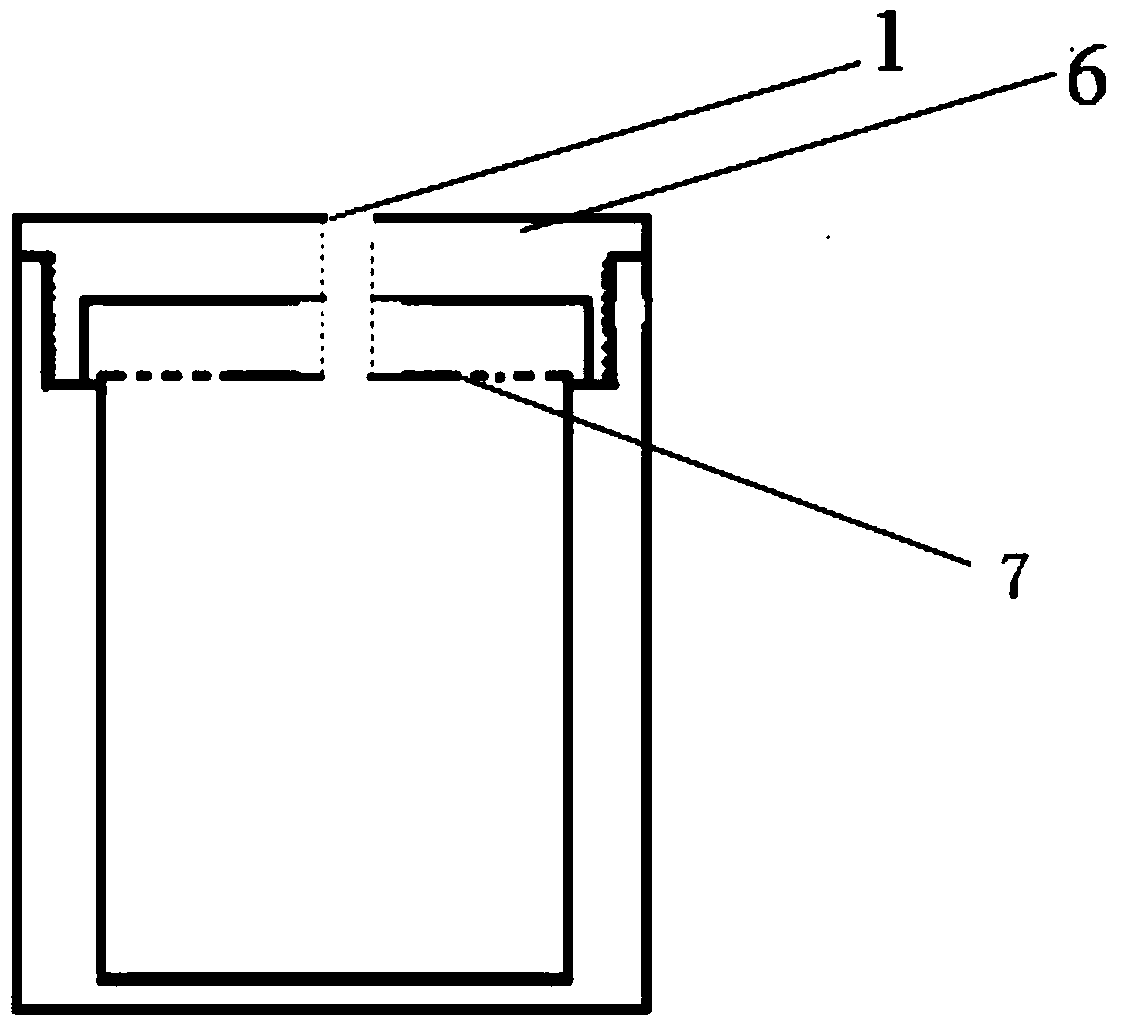

[0027] Take the vacuum chamber, and set the boron nitride crucible in the vacuum chamber, and powdery AlQ 3 placed in a boron nitride crucible. The boron nitride crucible is divided into a cover and a cavity, the cover and the cavity are tightly connected by threads, the cover is provided with a through hole, and the through hole is facing the upper substrate of the vacuum chamber; the cover and the cavity There is a thin metal sheet between the bodies, and the position corresponding to the through hole on the thin metal sheet is also a through hole. The addition of the thin metal sheet enhances the airtightness of the boron nitride crucible; the boron nitride crucible is cylindrical, The outer diameter is 3cm, the inner diameter is 1.5cm, and the height is 5cm.

[0028] Step 2, evacuate the vacuum chamber until the air pressure is 5×10 -5 The ultra-high vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com