Catalyst use for dimethyl ether catalytic combustion and its preparation method and application

A catalytic combustion and catalyst technology, applied in fuel, gas fuel, petroleum industry, etc., can solve problems such as carbon deposition, deactivation, and high price, and achieve the effects of reducing combustion temperature, reducing emissions, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

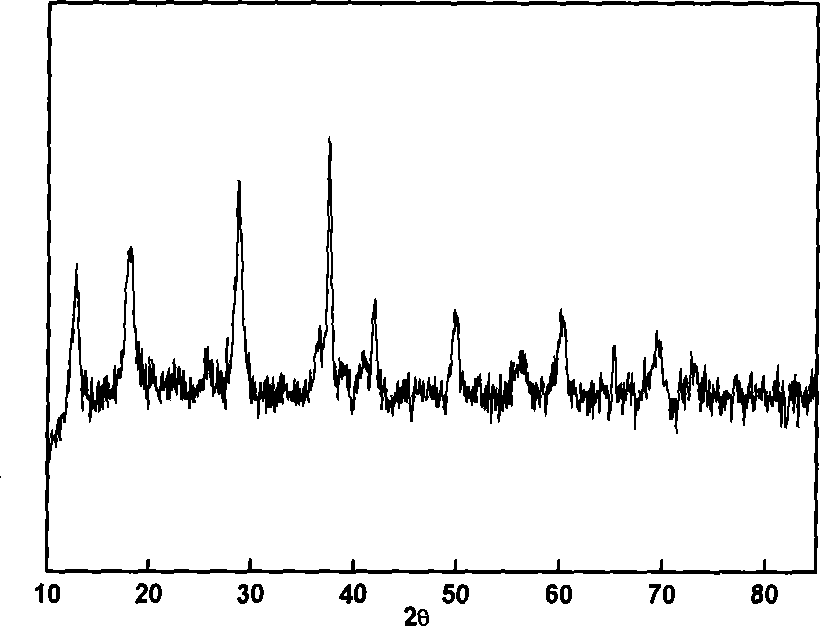

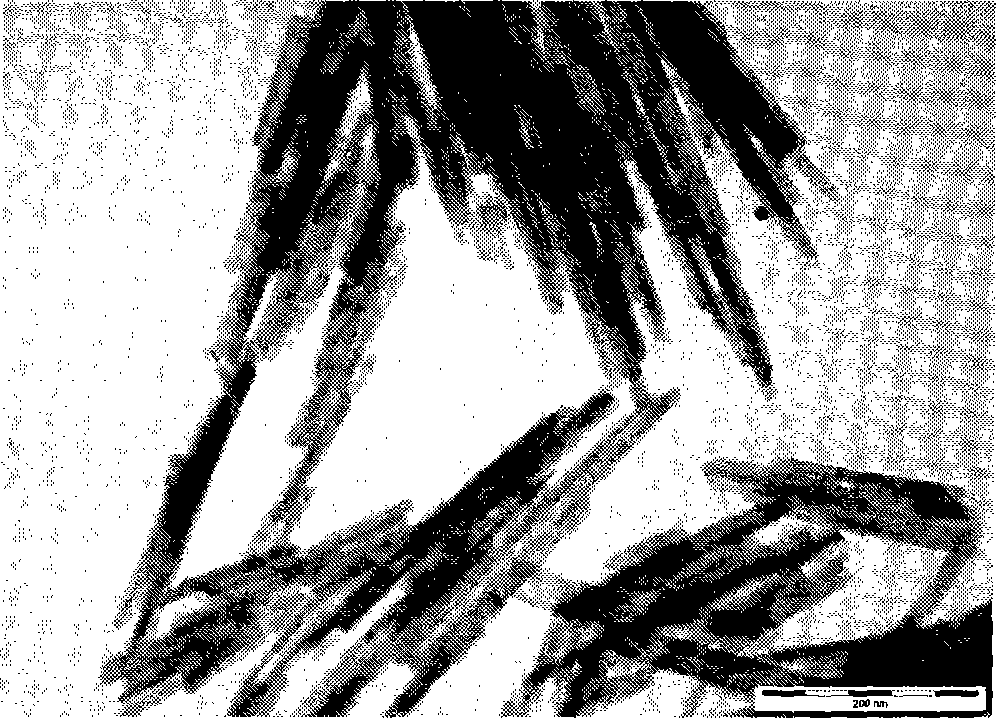

Embodiment 1

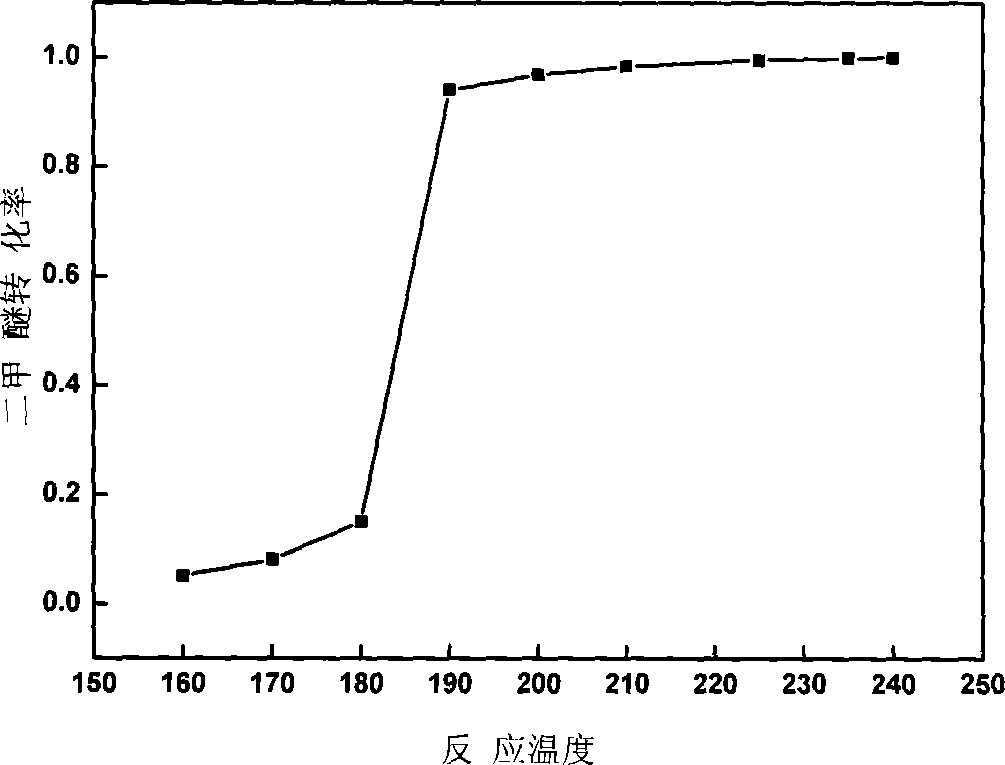

[0022] Under reflux in a water bath at 96°C, potassium permanganate and manganese sulfate were mixed into a uniform solution according to a molar ratio of 0.76, and concentrated nitric acid was added to adjust the pH value to less than 1, stirred vigorously for 24 hours, then filtered, and washed with deionized water and ethanol repeatedly , dried at 60°C for 12h, and then ground to obtain MnO 2 , weigh Fe(NO 3 ) 3 , and dissolved in a certain amount of methanol to make a 0.4mol / L solution, the MnO 2 with Fe(NO 3 ) 3 The methanol solution was mixed, stirred by magnetic force for 24 hours, then dried at 60°C for more than 12 hours, and then fired at 450°C at a rate of 2°C / min for 2 hours to obtain a doped Fe-OMS-2 material. The obtained catalyst is pressed into tablets and then crushed and sieved to 40-60 meshes for use.

[0023] The catalytic combustion reaction of dimethyl ether was carried out in a continuous flow fixed bed reactor. Quartz reaction tube with an inner d...

Embodiment 2

[0025] Under reflux in a water bath at 96°C, potassium permanganate and manganese sulfate were mixed into a uniform solution according to a molar ratio of 0.76, and concentrated nitric acid was added to adjust the pH value to less than 1, stirred vigorously for 24 hours, then filtered, and washed with deionized water and ethanol repeatedly , dried at 60°C for 12h, and then ground to obtain MnO 2 , weigh Co(NO 3 ) 2 , and dissolved in a certain amount of methanol to make a 0.4mol / L solution, the MnO 2 and Co(NO 3 ) 2 The methanol solution was mixed, stirred by magnetic force for 24h, then dried at 60°C for more than 12h, and then fired at 450°C at a rate of 4°C / min for 2h to obtain a doped Co-OMS-2 material. The obtained catalyst is pressed into tablets and then crushed and sieved to 40-60 meshes for use.

[0026] The catalytic combustion reaction of dimethyl ether was carried out in a continuous flow fixed bed reactor. Quartz reaction tube with an inner diameter of 8 mm,...

Embodiment 3

[0028] Under reflux in a water bath at 96°C, potassium permanganate and manganese sulfate were mixed into a uniform solution with a molar ratio of 1, and concentrated nitric acid was added to adjust the pH value to less than 1, stirred vigorously for 12 hours, then filtered, and washed with deionized water and ethanol repeatedly , dried at 60°C for 12h, and then ground to obtain MnO 2 , weigh Ni(NO 3 ) 2 , and dissolved in a certain amount of methanol to make a 0.4mol / L solution, the MnO 2 with Ni(NO 3 ) 2 The methanol solution was mixed, stirred by magnetic force for 24h, then dried at 60°C for more than 12h, and then fired at 350°C at a rate of 4°C / min for 6h to obtain a doped Ni-OMS-2 material. The obtained catalyst is pressed into tablets and then crushed and sieved to 40-60 meshes for use.

[0029] The catalytic combustion reaction of dimethyl ether was carried out in a continuous flow fixed bed reactor. A quartz reaction tube with an inner diameter of 8mm, a cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com