A distributed online detection system for ultrasonic lead key connection quality

An ultrasonic lead wire and detection system technology, applied in semiconductor/solid-state device testing/measurement, electrical components, electric solid-state devices, etc., can solve problems such as mutual influence between piezoelectric sensors and transducers, and changes in the structural characteristics of transducers. To achieve the effect of convenient online inspection, no interference with the production environment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

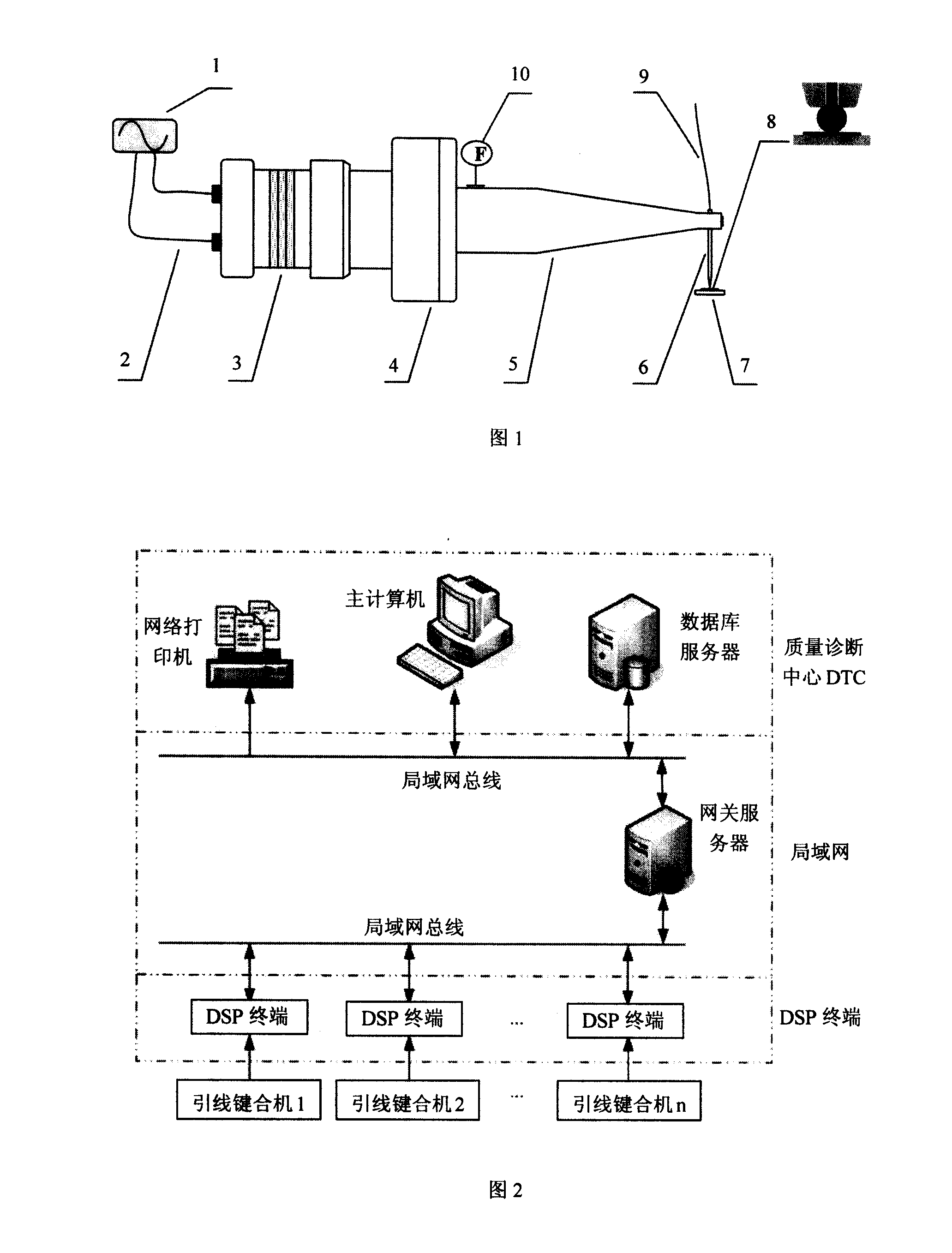

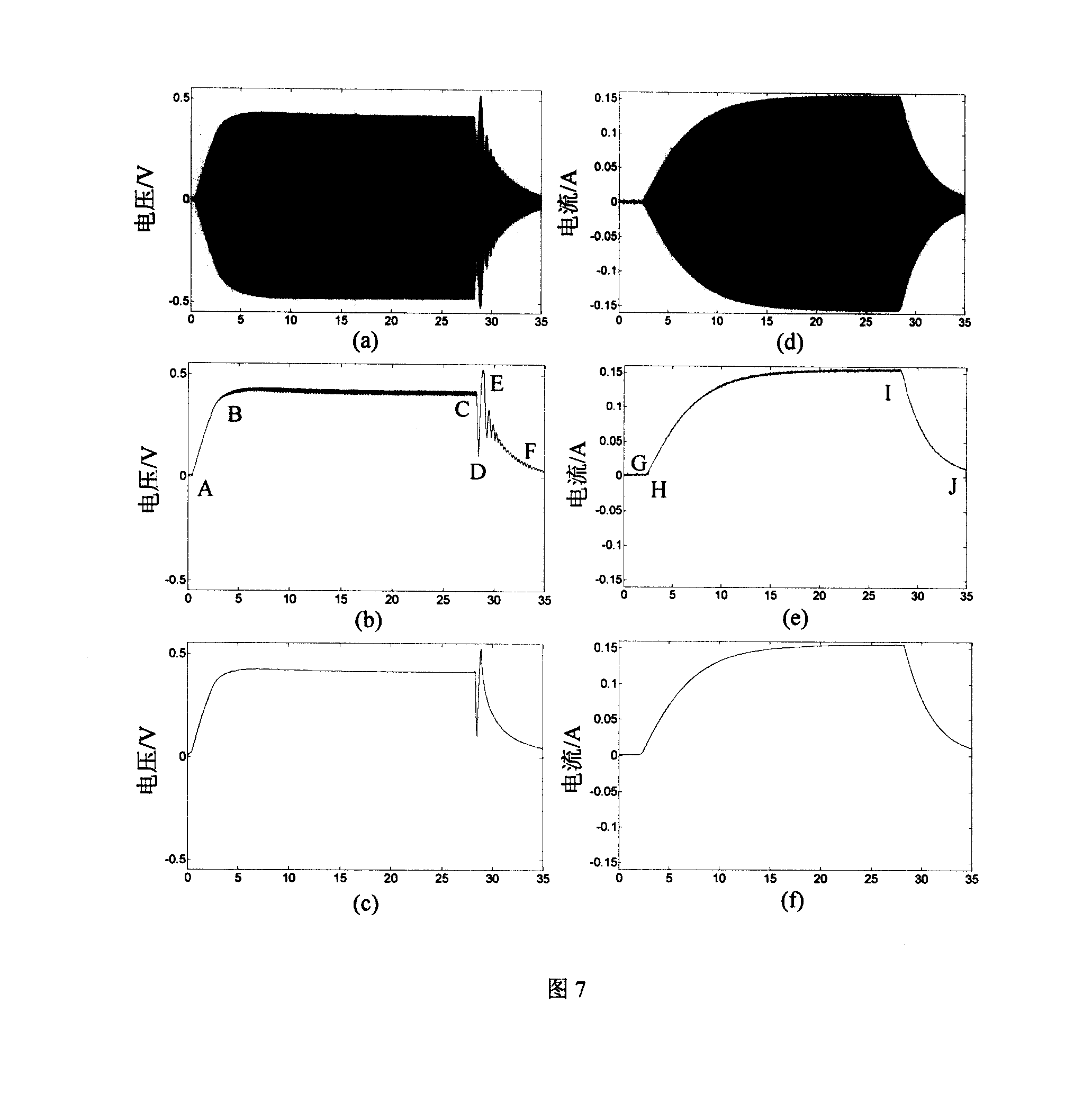

[0026] (1) Technical points of the invention

[0027] 1. In the way of information acquisition, based on the self-sensing characteristics of the piezoelectric transducer of the ultrasonic bonding system, the present invention directly obtains the input ultrasonic signal of the piezoelectric transducer, and uses this signal as an information carrier for identifying the bonding quality. Then, the bonding quality is identified by signal feature extraction and pattern recognition technology. Therefore, there is no need to install any sensors on the pad or on the transducer, which is low cost and does not interfere with the production environment.

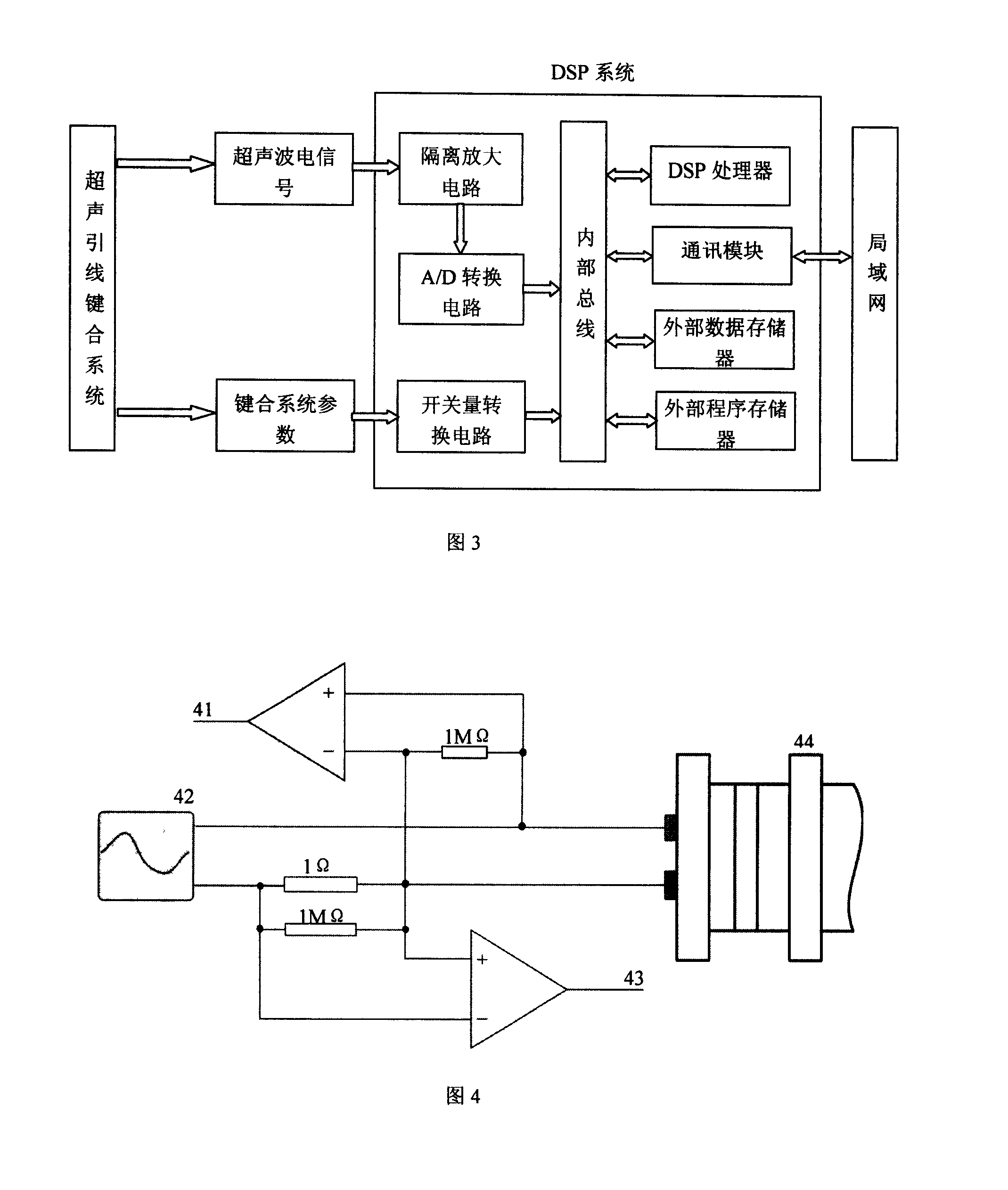

[0028] 2. Aspect information processing and system realization, the present invention utilizes DSP processor to carry out data acquisition and preprocessing, has improved the speed of data processing and detection system, and constitutes distributed system with detection center computer, can realize easily to a plurality of On-line pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com