Silicone hydride waste gas processing equipment

A technology for waste gas treatment and waste gas, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems that are not suitable for low-cost and large-scale production, and achieve the effect of low price, low production and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

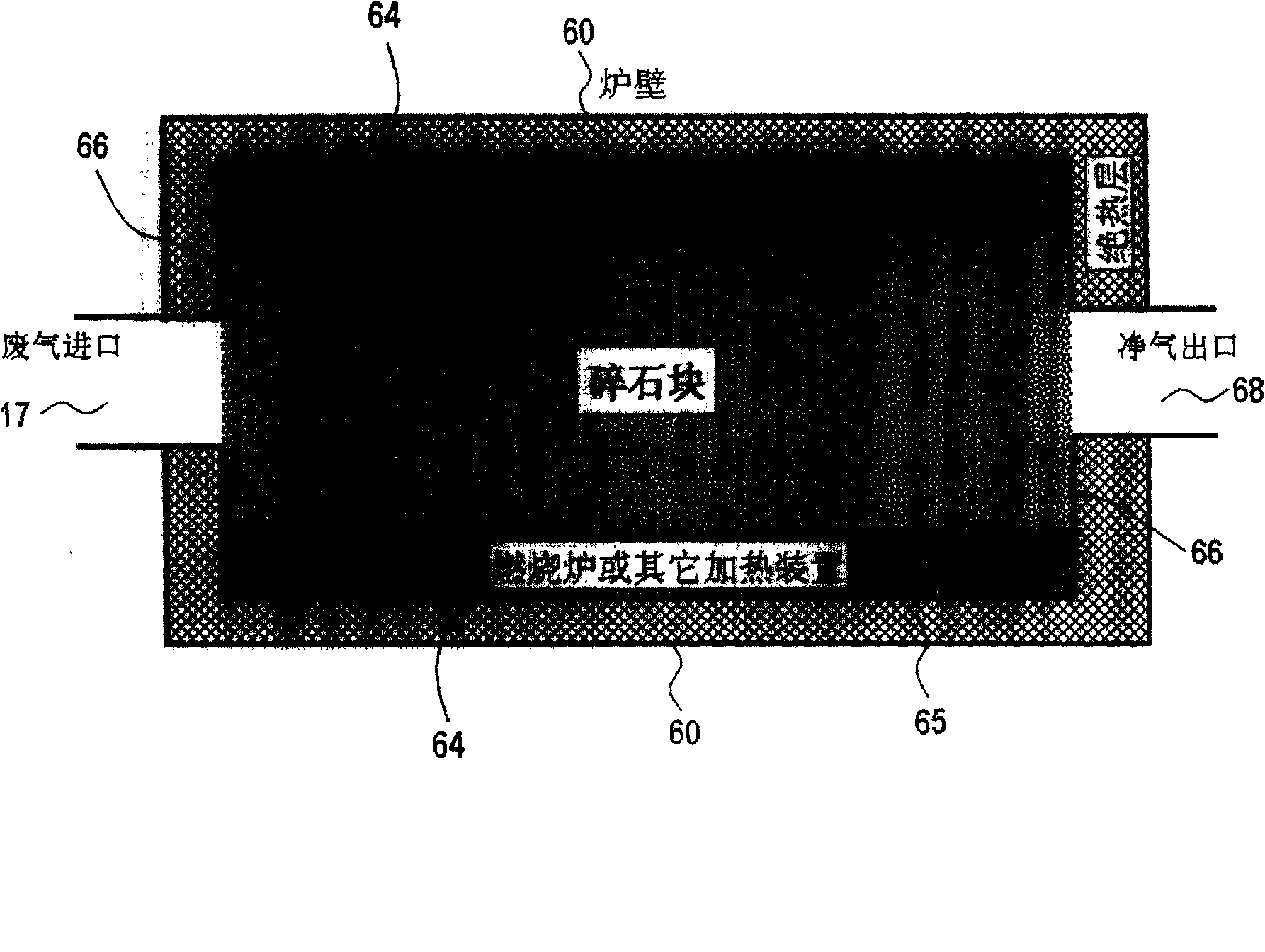

[0020] As shown in the drawings, the exhaust gas treatment system provided by the present invention is actually the simplest large-capacity thermal CVD system, consisting of the following main parts: a sealed metal furnace wall 60, preferably tubular, made of stainless steel or other strong made of heat-resistant metal or alloy; an internal steel pipe 68, which must be high temperature resistant and chemically stable, with a length of not less than 0.5 meters and a diameter of not less than 10 centimeters, placed in the center of the furnace wall; gas reactant 66 , its porous structure allows gas to pass through. At the same time, the reactant must remain stable at a high temperature of 700°C, and the reactant is compactly arranged in the inner steel pipe; the heating element 64, which can be made of an electric heater or a fossil fuel device, can keep the temperature of the gas reactant at Above 500°C, the heating element is wrapped around the inner steel pipe; the heat insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com