Chromium-molybdenum-seel flux welding wire for gas shielded arc welding

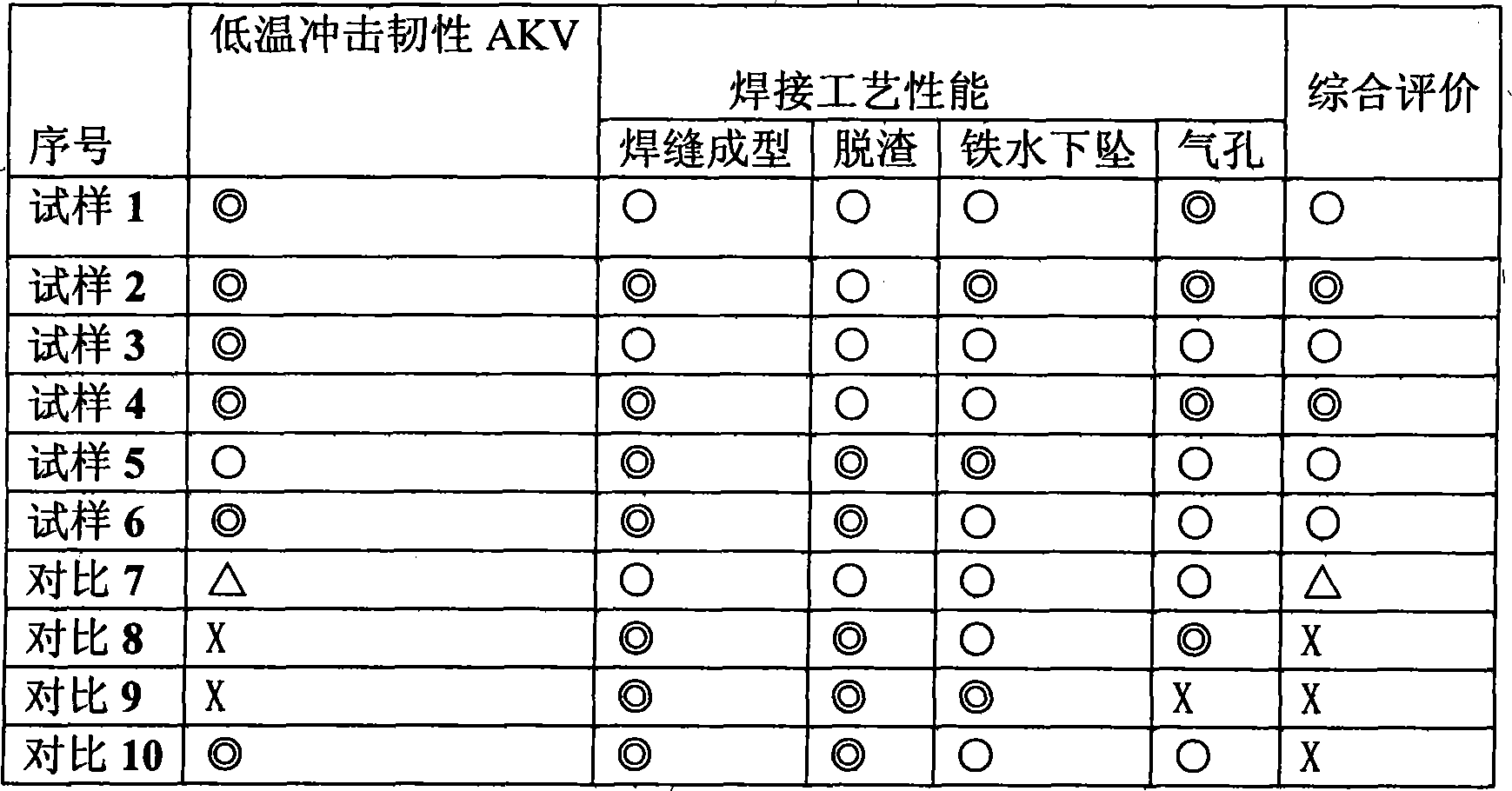

A technology of gas shielded welding and flux-cored welding wire, which is used in welding medium, welding equipment, welding/cutting medium/material, etc., and can solve the problems of inability to meet the requirements of high-grade heat-resistant steel weld manufacturability and all-position welding performance requirements. , to achieve good arc stability, reduce oxidation and burning loss, and smooth the weld.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with specific embodiment the present invention is described in further detail:

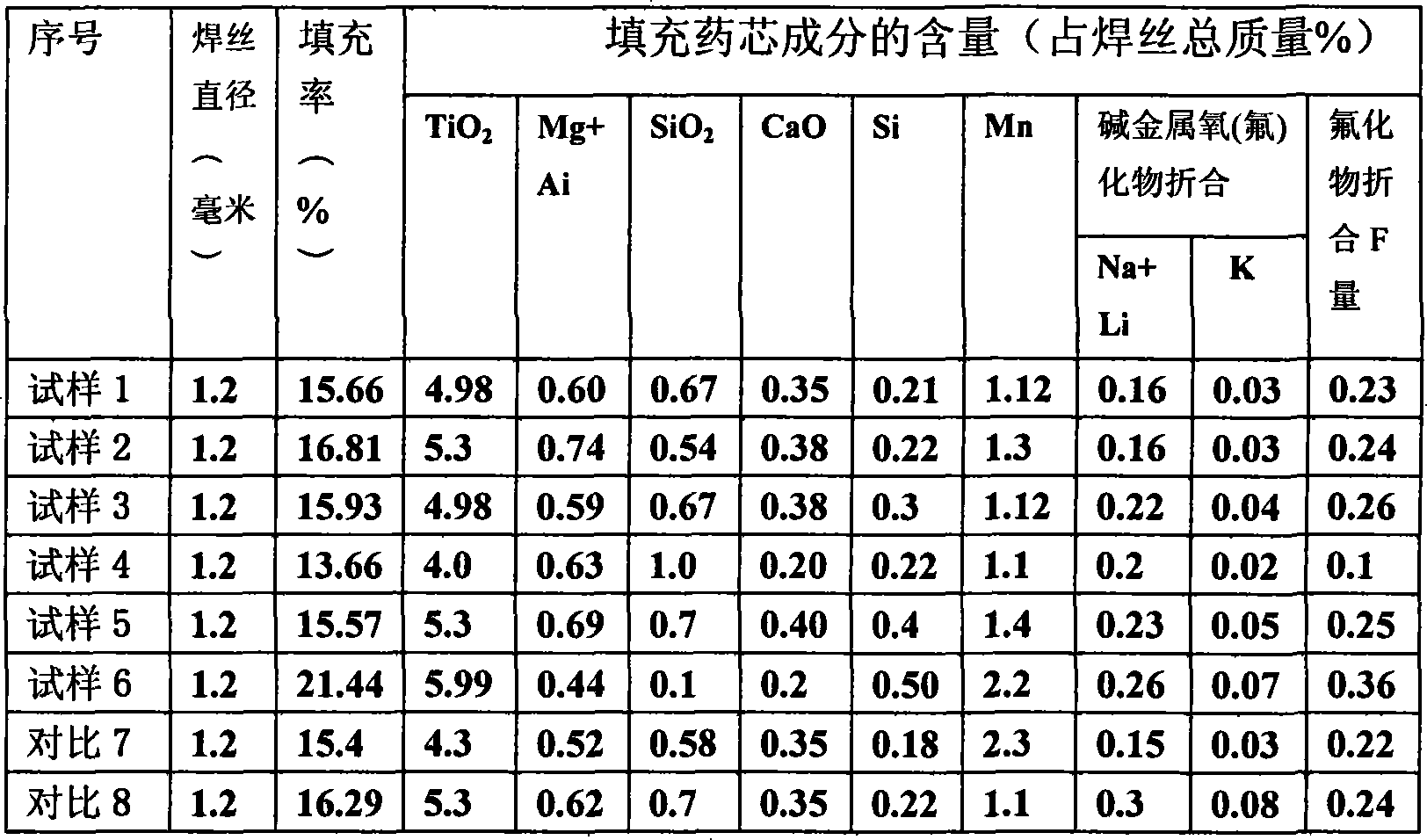

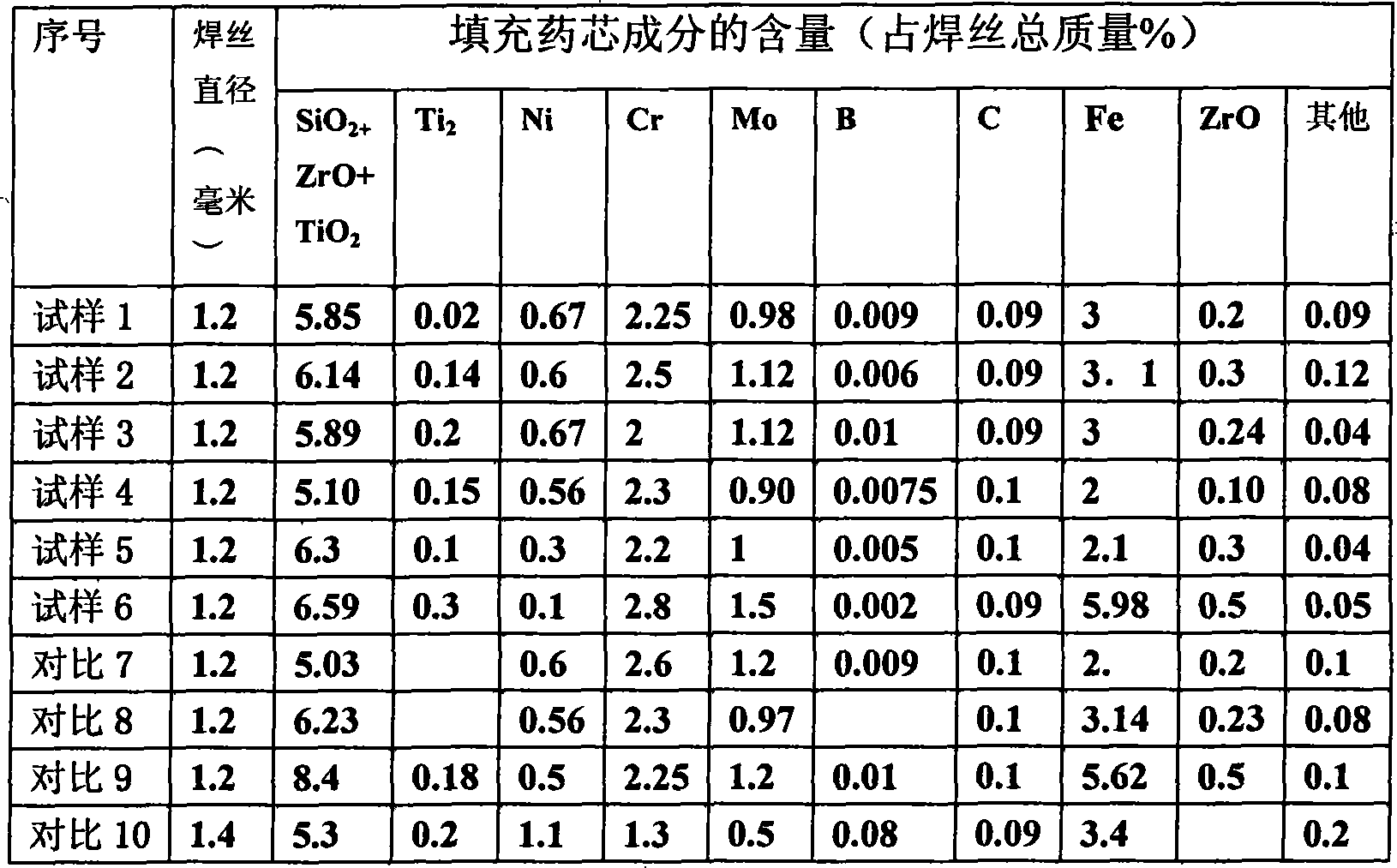

[0015] A chromium-molybdenum steel flux-cored welding wire for gas shielded welding, including a carbon steel sheath and a flux core, the composition mass % is 78-86% of the low-carbon steel sheath, and 14-22% flux core, and the composition and content of the flux core account for the total of the welding wire. The mass % is as follows: TiO 2 4-6, Si 0.2-0.5, Mn 1-2.2, SiO 2 0.1-1, ZrO 2 0.1-0.5, Cr 2-2.8, Mo 0.9-1.5, Ni 0-5, B 0.002-0.01, Ti0.02-0.3, Fe 2-6, Al+Mg 0.4-0.75, K, Na, Li alkali metal oxidation The content of K, Na and Li equivalent to fluoride and / or fluoride is 0.1-0.35, wherein K is 0.02-0.07, the sum of Na or Li or both is 0.08-0.3, and the equivalent of fluoride is F0.1-0.35. The carbon steel The sum of S, P, Sn and Bi in the outer skin and drug core powder is not greater than 0.035.

[0016] The steel sheath of the flux-cored welding wire of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com