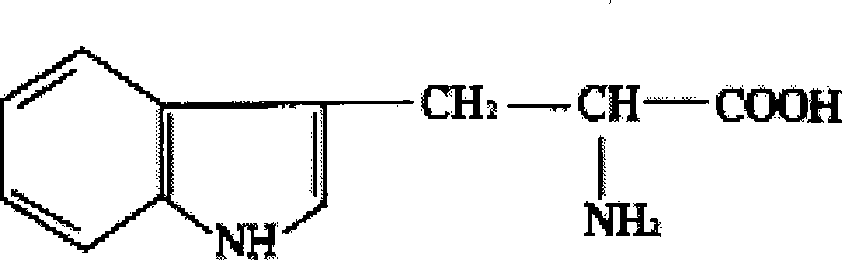

Purification method for tryptophane

A purification method and tryptophan technology, applied in the direction of organic chemistry and the like, can solve the problems of poor industrial applicability, high post-processing requirements, complicated and cumbersome processes, etc., and achieve the effects of convenient preparation, low cost, and simple process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Soak activated carbon in concentrated nitric acid, stir for 30 minutes, filter, wash with pure water until the washing liquid has no acid ions, dry, and then dry and activate at 120°C to obtain surface oxidized activated carbon.

[0022] 1.8 kg of tryptophan crude product with a content of 97.3wt% and a light transmittance of 53% was dissolved in 150 liters of pure water at 45° C., and 18 g of the above-mentioned surface-oxidized activated carbon was added and stirred for 30 minutes. The solution was passed through a 12 μm filter to remove the surface-oxidized activated carbon, and then used 0.22μm filter membrane for membrane filtration, take 50 liters of filtrate and concentrate it to about 17.5 liters in a pressure environment of 45°C and 10Kpa, cool to 15°C, stir for 1 hour, then heat up to 45°C to concentrate and continuously replenish the filtrate to maintain the volume of the concentrate About 23 liters, when the filtrate reaches 50 liters, cool down to 25°C, stir...

Embodiment 2

[0024] 1.8 kg of tryptophan crude product with a content of 97.3 wt% and a light transmittance of 53% was dissolved in 150 liters of purified water at 45°C, and 18 g of surface-oxidized activated carbon described in Example 1 was added, stirred for 30 minutes, and the solution was passed through a 12 μm filter to remove surface oxidation Activated carbon, and then use a 0.22μm filter membrane for membrane filtration, take 50 liters of filtrate and concentrate it to about 12 liters in a pressure environment of 60°C and 30KPa, cool to 25°C, stir for 2 hours, continue to heat up to 60°C to concentrate and continuously replenish the filtrate, Keep the concentrated volume at about 20 liters, add 50 liters of filtrate, cool down to 25°C, stir for 30 minutes, then raise the temperature to 60°C to concentrate and replenish the filtrate, keep the concentrated volume at about 20 liters, after adding all the filtrate, concentrate to 10 liter, cooled to 4°C, stirred for 2 hours, filtered, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com