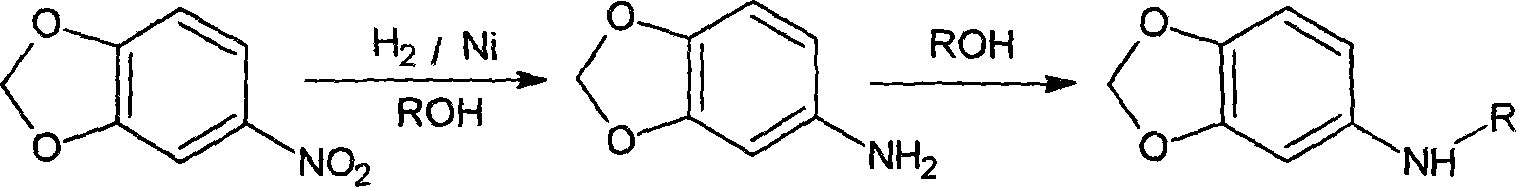

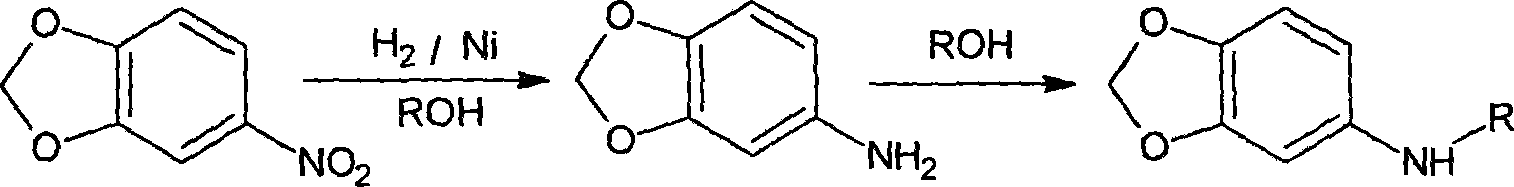

Method for producing N-alkyl-(3,4-methylenedioxy) aniline

A methylene dioxy, alkyl technology, applied in the field of N-alkyl-aniline, can solve problems such as complicated operation, achieve the effects of good selectivity, less environmental pollution, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0013] Example 1. Take 125g of 3,4-(methylenedioxy)nitrobenzene, 25g of Raney nickel catalyst, and 275g of dehydrated ethanol and put them into an autoclave, feed hydrogen, and react at 80°C / 2.5MPa for 2 hours. Replaced with nitrogen, raised the temperature to 170°C, and reacted for 10 hours. The product was concentrated and distilled under high vacuum, and 115g of fractions between 130-150°C were collected, analyzed by gas chromatography, the content of N-ethyl-(3,4-methylenedioxy)aniline was 96.4%, and the yield was 93.1% . 3,4-methylenedioxyaniline was not detected.

[0014] Example 2, 125g of 3,4-(methylenedioxy)nitrobenzene, 25g of Raney catalyst, and 275g of methanol were mixed and put into an autoclave, and hydrogen was passed through to react at 70°C / 2.5MPa for 2.5 hours. Replaced with nitrogen, raised the temperature to 160°C, and reacted for 10 hours. The product was concentrated and distilled under high vacuum, and 106g of fractions between 125-145°C were collecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com