Full-fluorine ion switching fibre and manufacture method thereof

A technology for exchanging fibers and perfluorinated ions, which is applied in the direction of cation exchange materials, fiber types, fiber treatment, etc., can solve the problems of inconvenient preparation of fluorine-containing ion exchange fibers, and achieve fast adsorption, easy elution, and simple preparation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

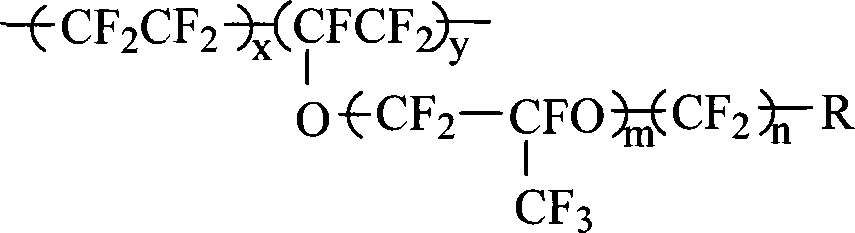

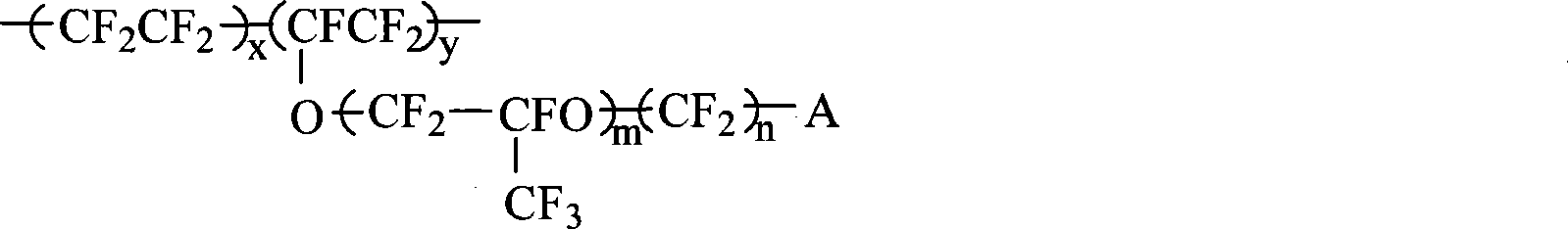

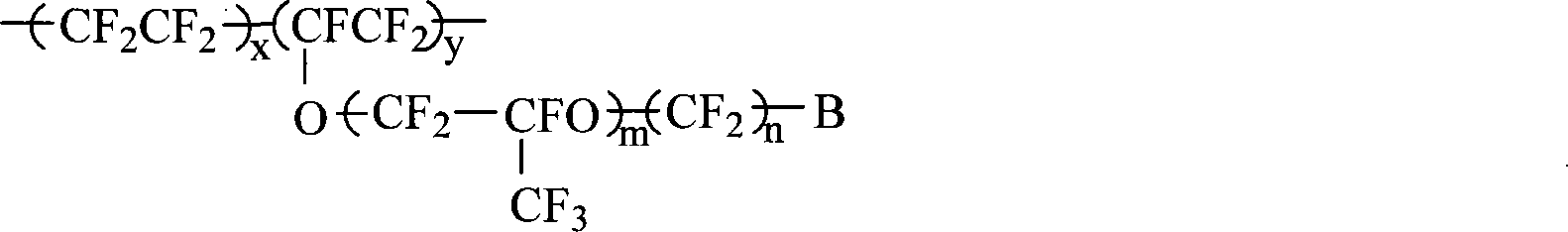

Method used

Image

Examples

Embodiment 1

[0034] 1) Change the terminal group to -SO 2 The perfluorosulfonic acid fiber-forming resin of F is melt-spun, and the spinning temperature is 280° C., and the spinning speed is 500 m / min to obtain a precursor fiber; 2) the precursor fiber is mixed with 6mol / L NaOH solution at 95° C. React for 48 hours, and then with 2mol / LH 2 SO 4 After reacting for 3 hours, a perfluorinated ion exchange fiber containing sulfonic acid groups was obtained. The monofilament strength of the fiber exceeds 30MPa, and the thermal decomposition temperature exceeds 400°C. At 50°C and CuCl 2 The solution is ion-exchanged, and the exchange equilibrium is reached within 2 hours, and the Cu 2+ The exchange capacity reaches 0.4meq / g.

Embodiment 2

[0036] 1) Change the terminal group to -SO 2 The perfluorosulfonic acid fiber-forming resin of Cl carries out melt spinning, and spinning temperature is 235 ℃, and spinning speed is 650m / min, obtains precursor fiber; 2) Precursor fiber is mixed with 6mol / L NaOH liquid After reacting for 50 hours, perfluorinated ion exchange fibers containing sodium sulfonate groups were obtained. The monofilament strength of the fiber exceeds 25MPa, the thermal decomposition temperature exceeds 380°C, and it can be mixed with CaCl at 70°C 2 The solution is ion-exchanged, and the exchange equilibrium is reached within 1.2 hours, and the Ca 2+ The exchange capacity reaches 0.58meq / g.

Embodiment 3

[0038] 1) Change the end group to -COOCH 3 The perfluorocarboxylic acid fiber-forming resin is melt-spun, the spinning temperature is 225°C, and the spinning speed is 350m / min to obtain the precursor fiber; 2) the precursor fiber is reacted with 6mol / L NaOH solution at 90°C 50 hours, and then react with 3mol / L HCl for 3 hours to obtain perfluorinated ion exchange fibers containing carboxylic acid groups. The monofilament strength of the fiber exceeds 25MPa, and the thermal decomposition temperature exceeds 350°C. It is exchanged with NaCl solution at 60°C, and the exchange equilibrium is reached within 1.5 hours. + The exchange capacity reaches 1.02meq / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Monofilament strength | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com