Preparation of activated carbon fibre filtering core

A technology of activated carbon fiber and filter element, which is applied in the field of preparation of activated carbon fiber filter element, can solve the problems of reducing the specific surface area of activated carbon or activated carbon fiber, the growth of bacteria on the filter element, and the large content of filter element binder, so as to improve purification and sterilization effect, prevention of secondary pollution, effect of low binder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of an activated carbon fiber filter core, the method comprising the following steps:

[0019] 1) The activated carbon fibers loaded with bactericides (salts containing silver, copper, zinc and other ions) are pulverized, then mixed with polypropylene binder, and beaten in the beating pool 1, water, activated carbon fibers, hot-melt adhesive The weight ratio of binder is 1000:15:0.5.

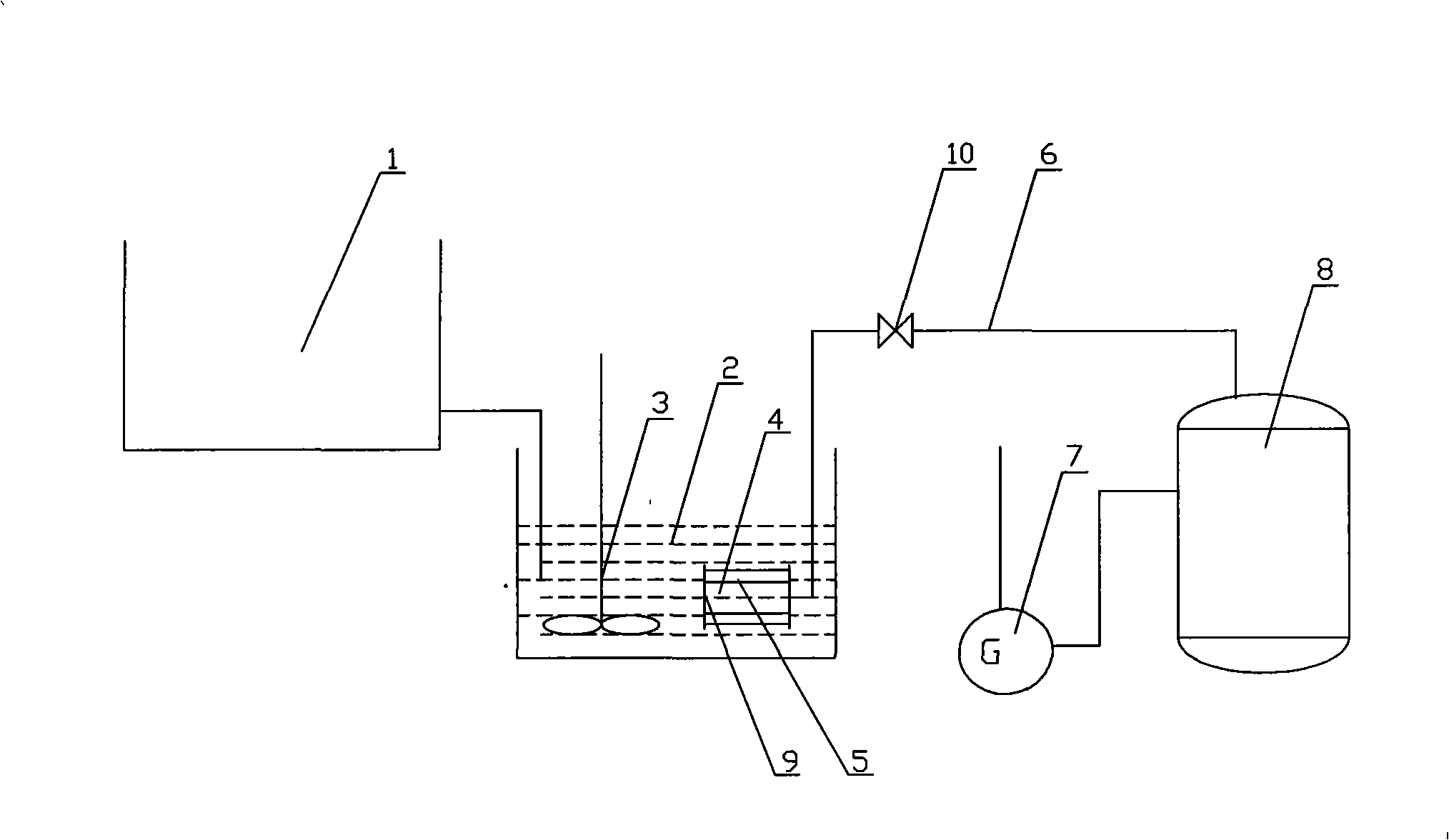

[0020] 2) The material after beating is put into the suction pool 2 to be stirred by the stirring pump 3, and the stirring is uniform.

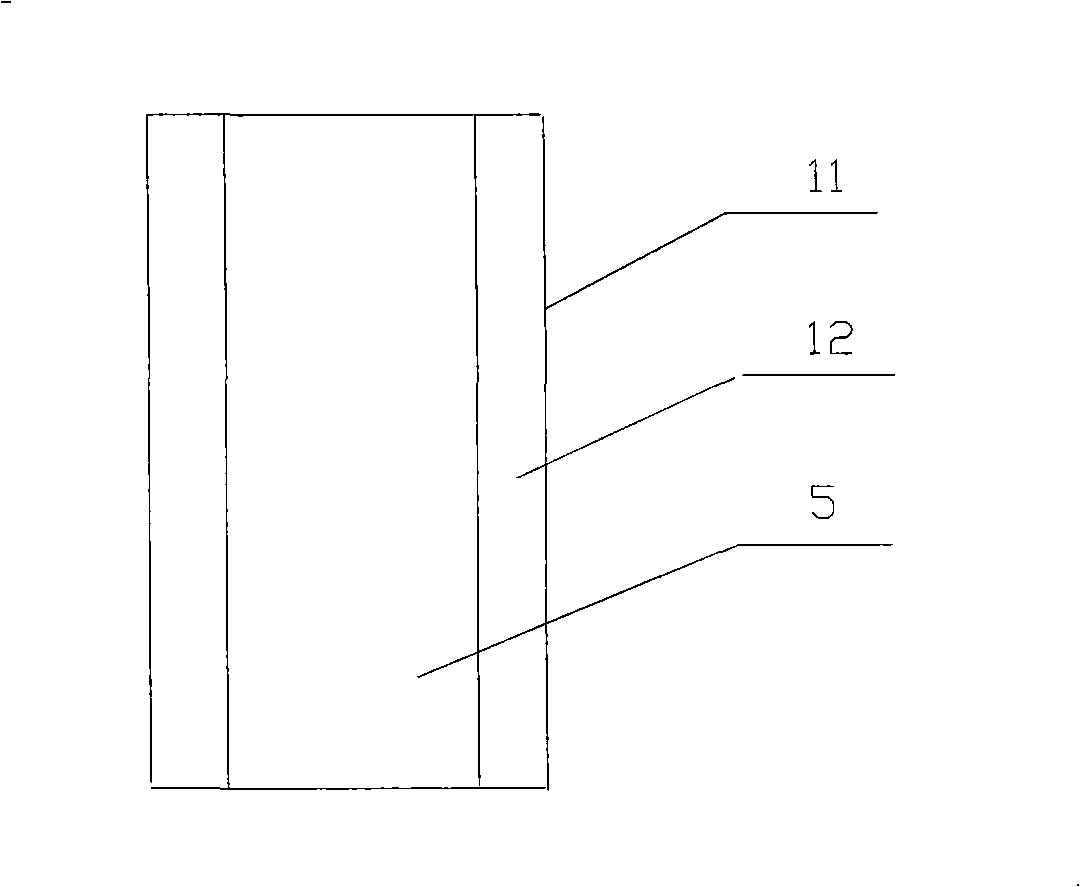

[0021] 3) Put the aspirator with the inner mold installed into the suction pool 2 to suck for 1-50 minutes, the activated carbon fiber filter core is molded in the inner mold of the aspirator to form the adsorption layer 12, and the inner mold is proposed; During the suction process, water enters the filter cloth 5 covered by the frame 4 and enters the buffer tank 8 through the suction pipe 6, and the buffer tank 8 is evacuated by th...

Embodiment 2

[0025] A preparation method of an activated carbon fiber filter core, the method comprising the following steps:

[0026] 1) Grinding activated carbon fibers loaded with fungicides (salts containing silver, copper, zinc, etc.) and activated carbon, the proportion of activated carbon is 50% by weight of the mixture, and then mixed with polyamide binder, in the beating pool 1 for beating, the weight ratio of water, activated carbon fiber mixture, and polyamide binder is 1000:5:1.

[0027] 2) The material after beating is put into the suction pool 2 to be stirred by the stirring pump 3, and the stirring is uniform.

[0028] 3) Put the aspirator with the inner mold installed into the suction pool 2 and suck for 1-5 minutes, the activated carbon fiber filter core is molded in the inner mold of the aspirator to form the adsorption layer 12, and the inner mold is lifted to form Adsorption layer 12; during the suction process, water enters the filter cloth 5 coated on the outside of ...

Embodiment 3

[0031] A preparation method of an activated carbon fiber filter core, the method comprising the following steps:

[0032] 1) The activated carbon fiber pulverization that will be loaded with bactericide (containing the salts of silver, copper, zinc etc.) is mixed with activated carbon, and activated carbon accounts for 20% by weight of the mixture, and then mixed with hot-melt adhesive, in the beating pool 1 The beating is carried out in the middle, and the weight ratio of water, activated carbon fiber mixture and polyester binder is 1000:20:2.

[0033] 2) The material after beating is put into the suction pool 2 to be stirred by the stirring pump 3, and the stirring is uniform.

[0034] 3) Put the aspirator with the inner mold installed into the suction pool 2 to suck for 1-5 minutes, the activated carbon fiber filter core is molded in the inner mold of the aspirator to form the adsorption layer 12, and the inner mold is proposed; During this suction process, water enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com