Both-end water-generating immersed hollow fiber film component

A fiber membrane and submerged technology, applied in the field of submerged hollow fiber membrane modules, can solve problems such as unreasonable aeration methods, inability to detect and repair, and uneven gas distribution, so as to reduce the frequency of backwashing and chemical cleaning. Easy installation and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

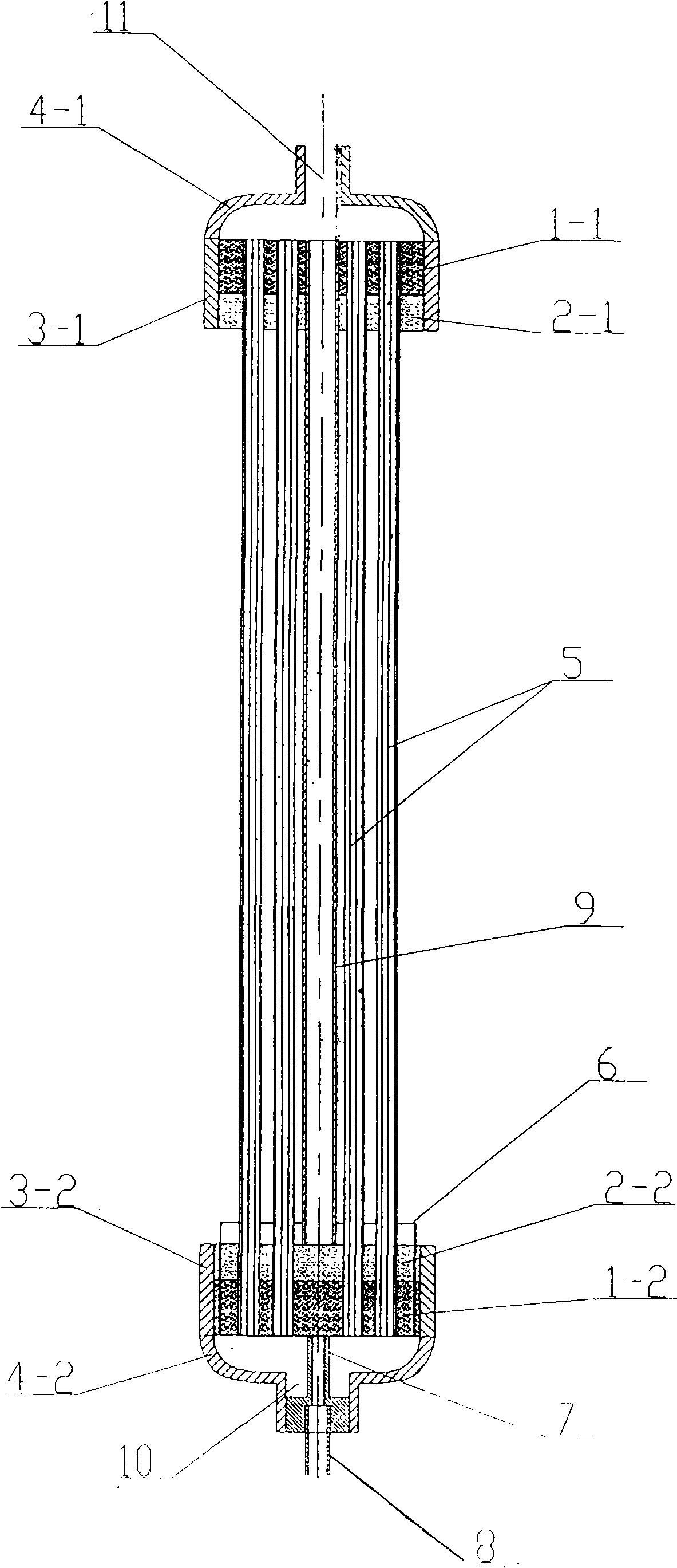

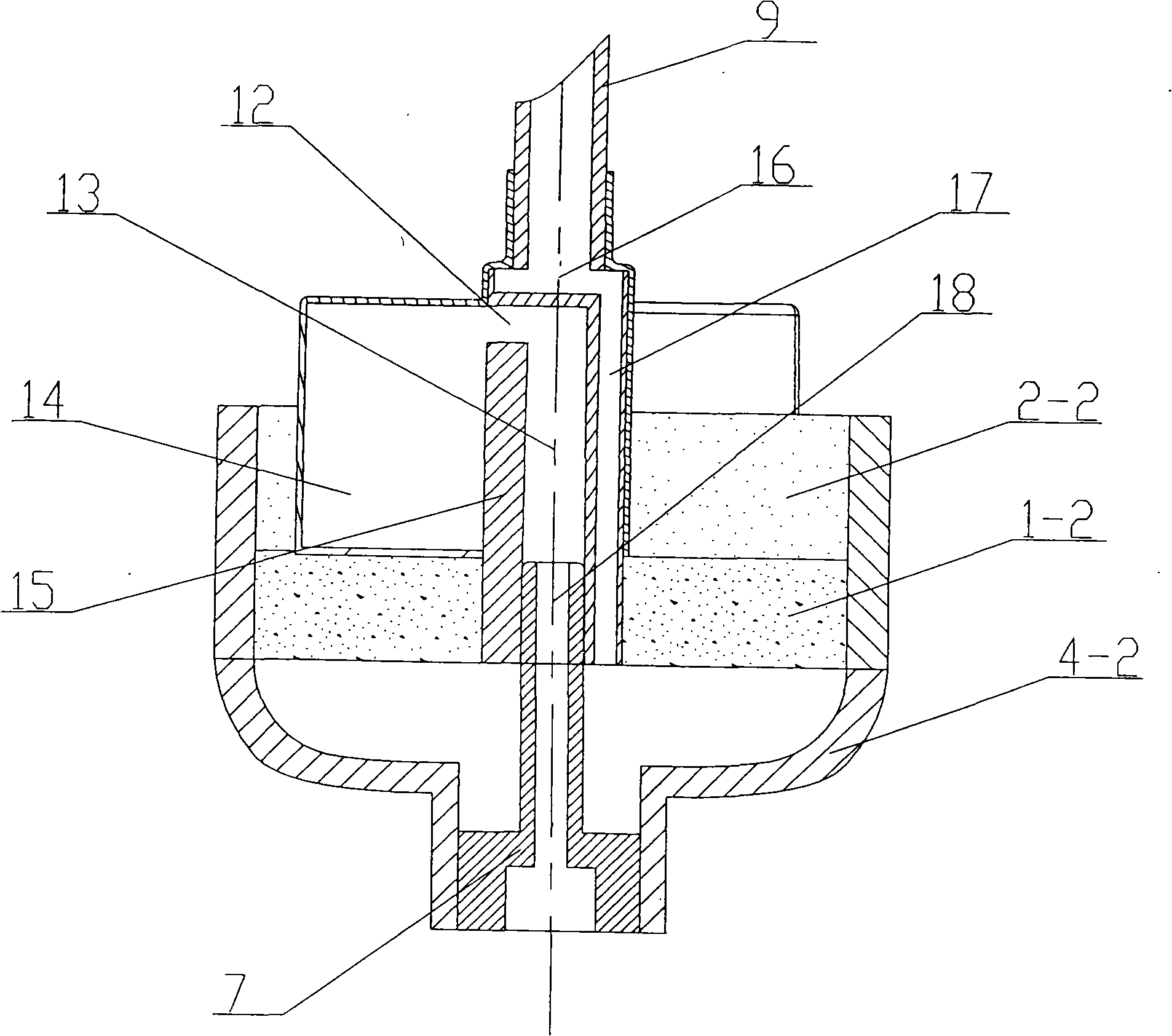

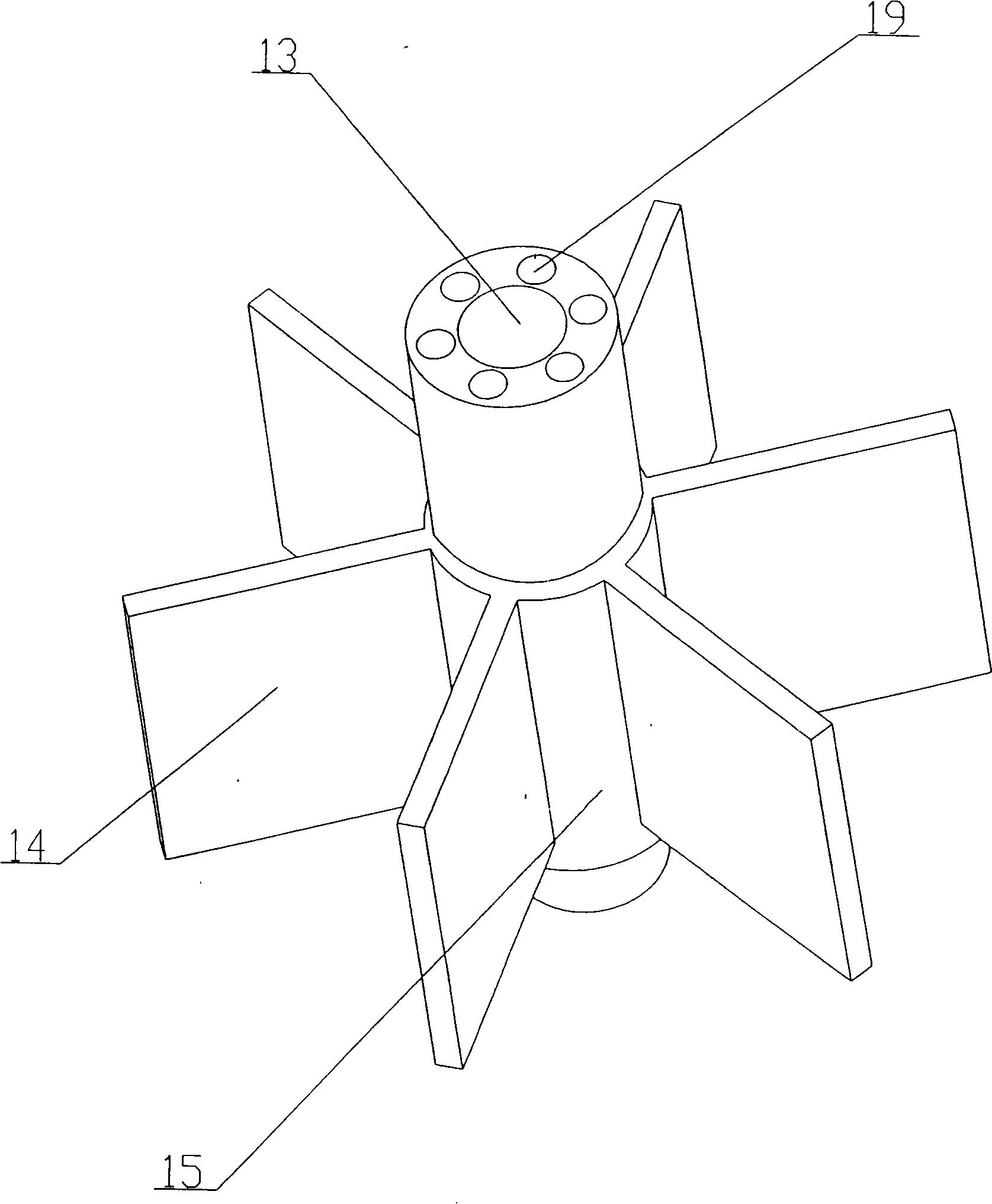

[0021] The schematic diagram of the double-end water production submerged hollow fiber membrane module of the present invention is as follows figure 1 As shown, a plurality of hollow fiber membranes 5 are fixed by two sealing layers poured in the screw barrels 3-1, 3-2. In order to improve the service life of the membranes, the sealing layers are made of epoxy resin sealing layers 1-1, 1 -2 and polyurethane sealing layer 2-1, 2-2. Because the polyurethane sealing layer is relatively soft, it is beneficial to protect the film filaments. The screw barrel 3-1 is connected with the screw cover 4-1, the screw barrel 3-2 is connected with the screw cover 4-2, and the hollow part of each hollow fiber membrane is opened on both ends of the sealing layer. An air inlet 10 is provided on the screw cover 4-2, and a water outlet 11 is provided on the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com