Boiling-free silicane cross-linking polyolefin composition

A silane cross-linking and polyolefin technology is applied in the field of cross-linking polyolefin compositions and their preparation, which can solve the problems of affecting the peroxide initiation efficiency, insufficient product cross-linking degree, low cross-linking efficiency, etc., and shorten the production period. , good thermal aging performance, eliminating the effect of cumbersome links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

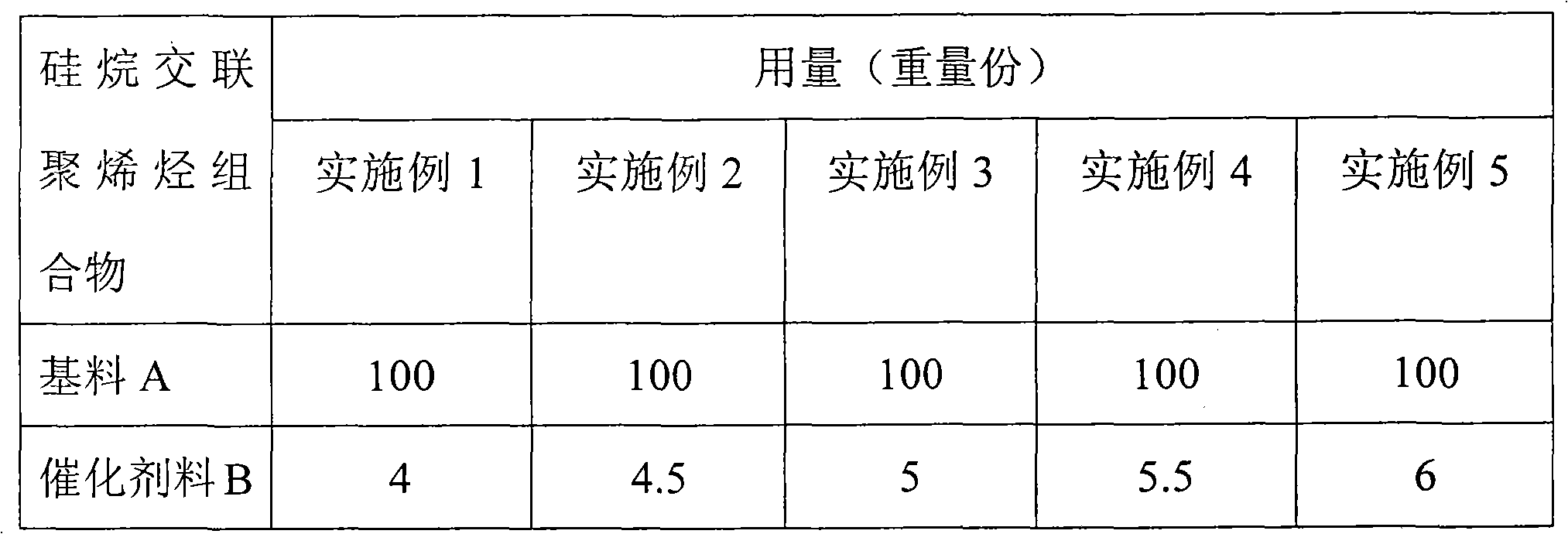

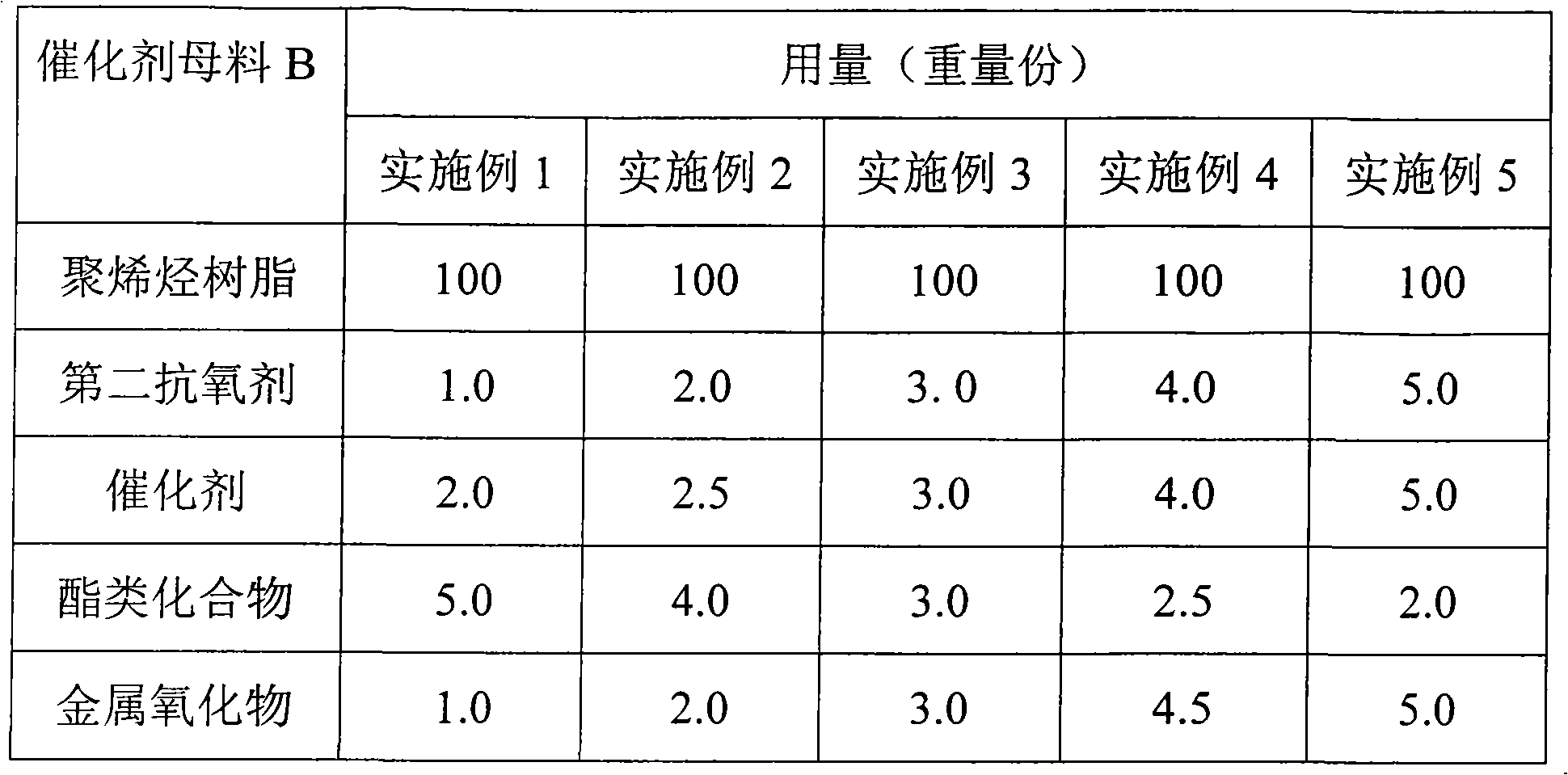

Examples

Embodiment 1

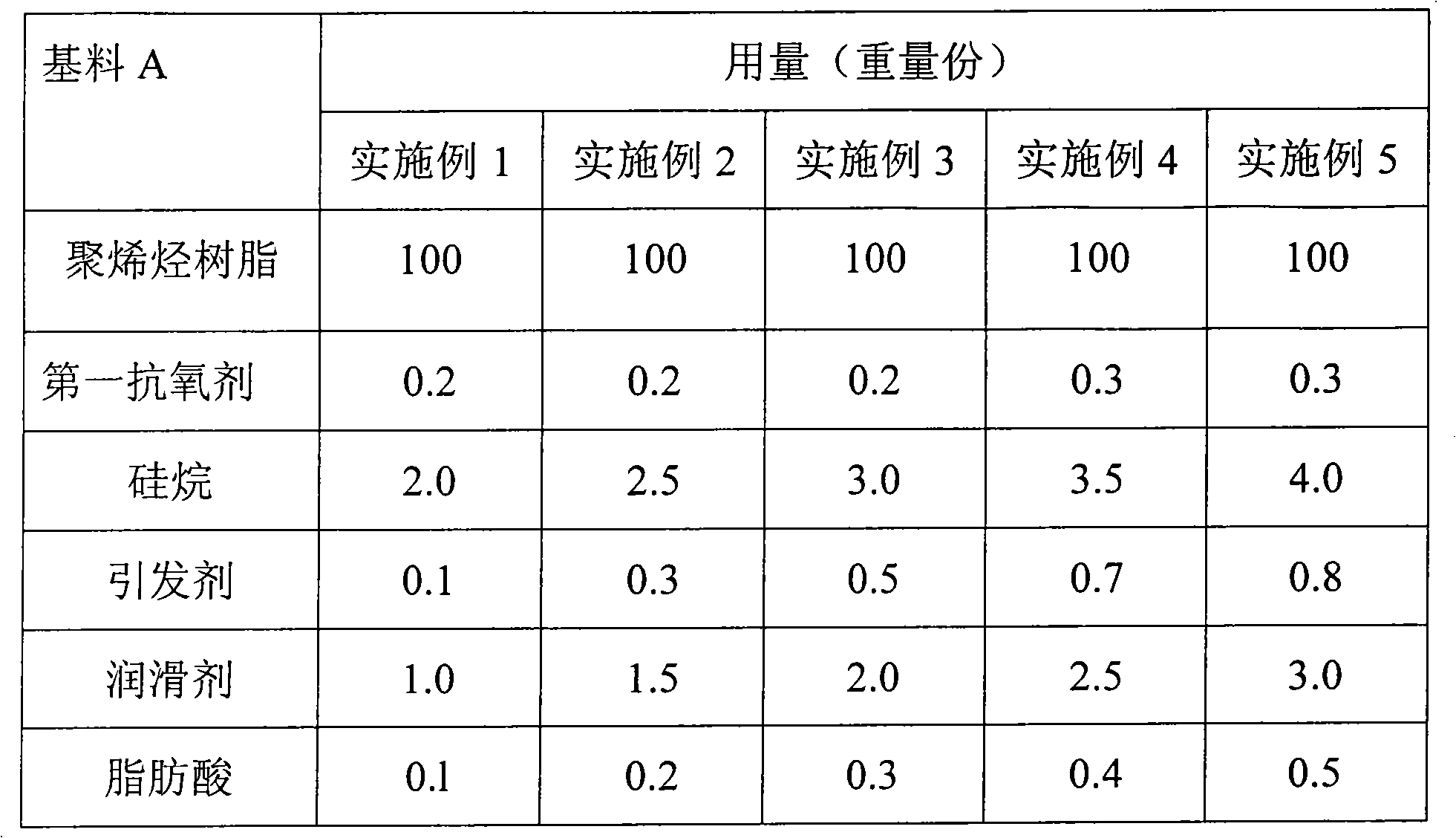

[0017] In Example 1, the silane in Base A is vinyltrimethoxysilane, the silane in Example 2 is vinyltriethoxysilane, and the silane in Example 3 is vinyltrimethoxysilane and vinyltrimethoxysilane. The mixture of triethoxysilane 1:1, the silane in Example 4 is the mixture of vinyltrimethoxysilane and vinyltriethoxysilane 7:3, the silane in Example 5 is vinyltrimethoxysilane A 3:7 mixture of silane and vinyltriethoxysilane.

[0018] In Examples 1, 2, 3, the initiator in Base A was dicumyl peroxide, and in Examples 4 and 5, dibenzoyl peroxide.

[0019] In the embodiment, the lubricant in base material A is a mixture of polyethylene wax and fluorine-containing rheological agent,

[0020] In the embodiment, the fatty acid in base material A is stearic acid 1801 distributed by Guangzhou Qisheng Chemical Industry.

[0021] To prepare base material A, first take 100 parts of polyolefin resin, 0.2-0.3 parts of first antioxidant, 2.0-4.0 parts of silane, 0.1-1.0 parts of initiator, 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com