Bromine-carbon pnenolic aldehyde epoxy powder fire-proof paint and preparation method thereof

The technology of bromocarbon novolac epoxy and bromocarbon novolac epoxy resin is applied in the field of preparation of bromocarbon novolac epoxy powder fireproof coatings, and can solve the problems of small molecular weight, aging decay, failure to achieve fire resistance and flame retardant, and the like. More cross-linking active sites, overcoming aging decay, and good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

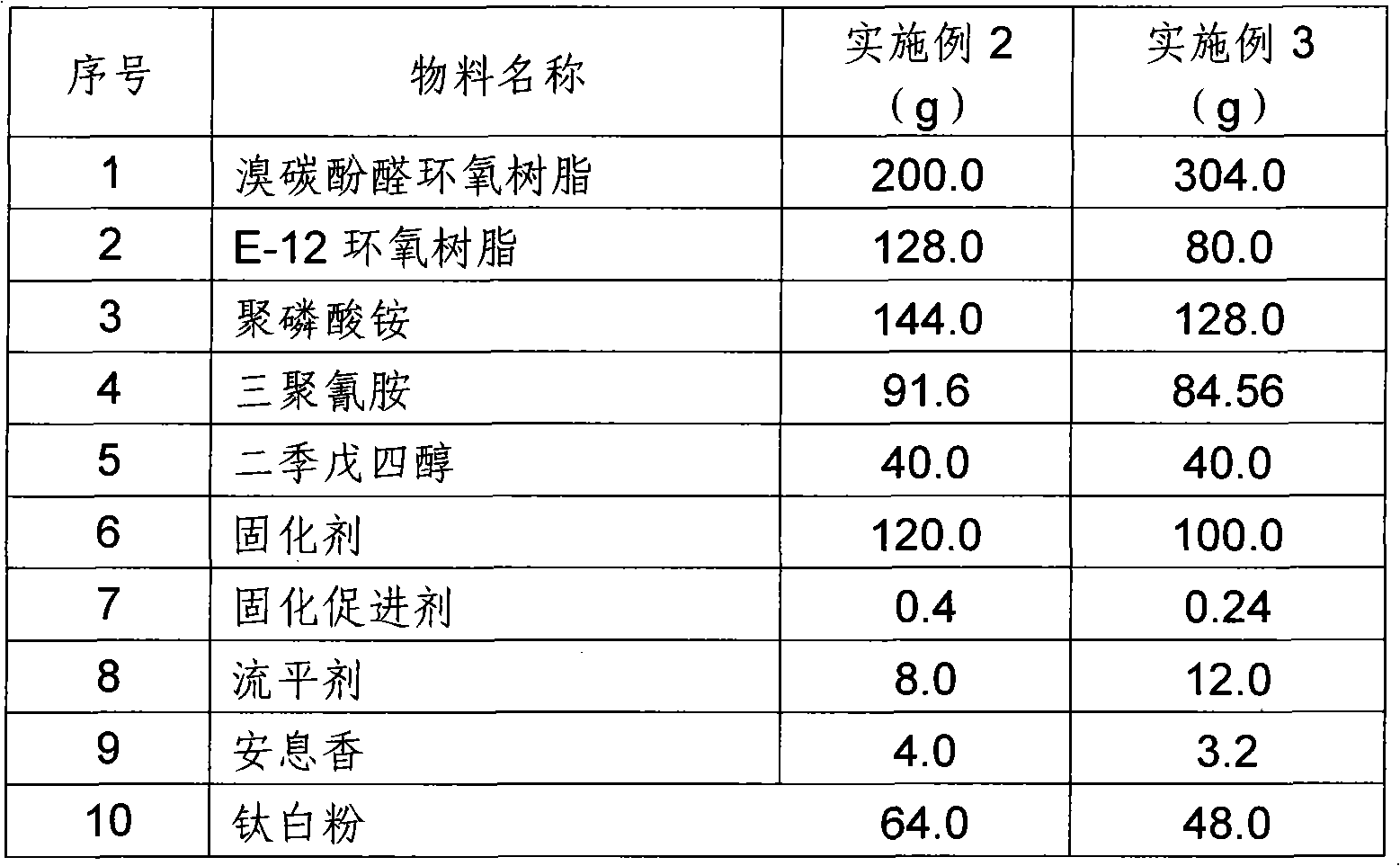

[0044] The preparation method of bromocarbon novolac epoxy powder fireproof coating of the present invention, prepares materials according to above-mentioned formula, and its steps are:

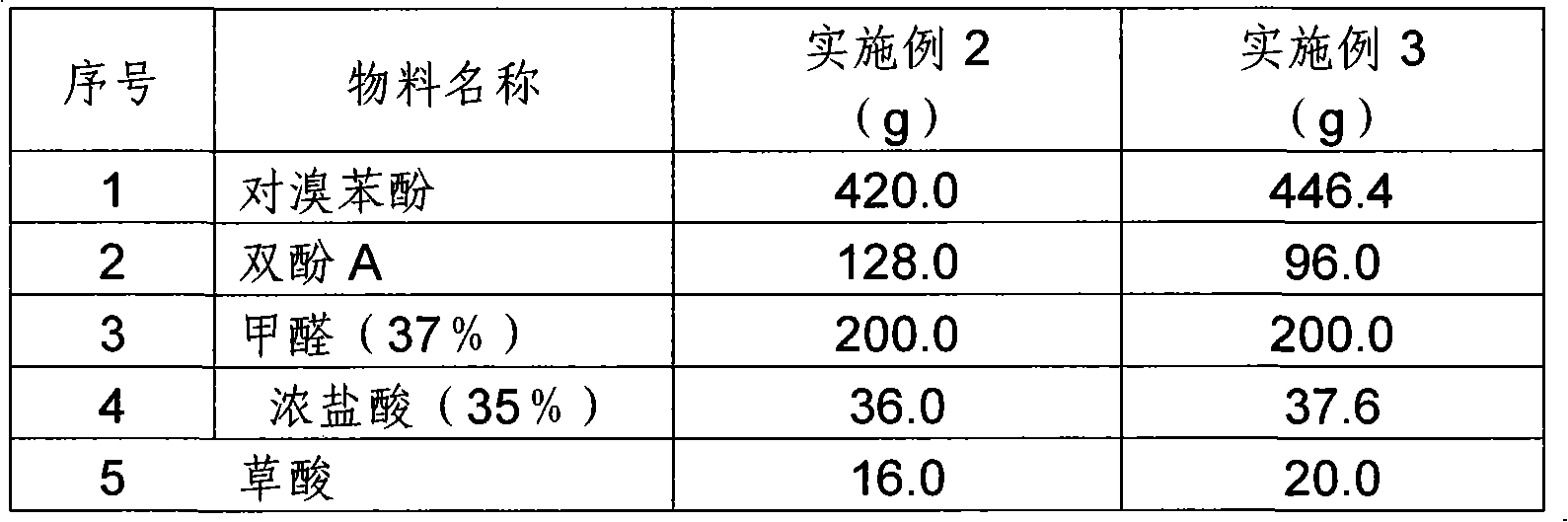

[0045] (1) Add p-bromophenol and bisphenol A to the reactor, then add formaldehyde (37%), stir and heat up to dissolve, dissolve oxalic acid in hot water and add it to the reactor; the temperature is raised to 80°C, and the system automatically heats up to 98°C, Keep reflux at 98-100°C for 2 hours; cool down to 75°C, add hydrochloric acid, raise the temperature of the system to 98°C and keep for 15 minutes, take a sample and measure the sample until it is not sticky in 30°C water, wash it twice with cold water, use 10 % sodium hydroxide solution to neutralize to pH = 7-7.5, continue to wash 5 times, the washing temperature is 60-70 °C; vacuum dehydration, the maximum temperature does not exceed 130 °C, the softening point of the sample is above 100 °C, release the vacuum, cool down Feed to ob...

Embodiment 1

[0052](1) Add 392.8kg of p-bromophenol and 168.0kg of bisphenol A to the reactor, then add 184.0kg of formaldehyde (37%), stir and heat up to dissolve, dissolve 16.0kg of oxalic acid with hot water and add to the reactor; heat up to 80°C , the system heats up to 98°C by itself, and maintains reflux at 98-100°C for 2 hours; cools down to 75°C, adds 39.2kg of hydrochloric acid, heats up the system to 98°C and maintains it for 15 minutes, takes a sample to measure the sample until it is not sticky in 30°C water, and washes it with cold water 2 times, neutralize with 10% sodium hydroxide solution to pH = 7-7.5, continue to wash 5 times, the washing temperature is 60-70°C; vacuum dehydration, the maximum temperature does not exceed 130°C, and the softening point is above 100°C by sampling. Release the vacuum, cool down and discharge to obtain bromocarbon phenolic resin.

[0053] (2) Put 230.4kg of bromocarbon phenolic resin and 104.8kg of epichlorohydrin into the reaction kettle, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com