Method for preparing Ni based single-crystal refractory alloy by employing combination of seed crystal method and screw selecting method

A high-temperature alloy and spiral crystal selector technology, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of low success rate of single crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] The steps for preparing Ni-4Cr-9Co-8W-2Mo-6Al-6.5Ta-2Re single crystal superalloy material with orientation and excellent solidification structure are as follows:

[0089] The first step is to prepare the seed crystal of Ni-4Cr-9Co-8W-2Mo-6Al-6.5Ta-2Re single crystal superalloy;

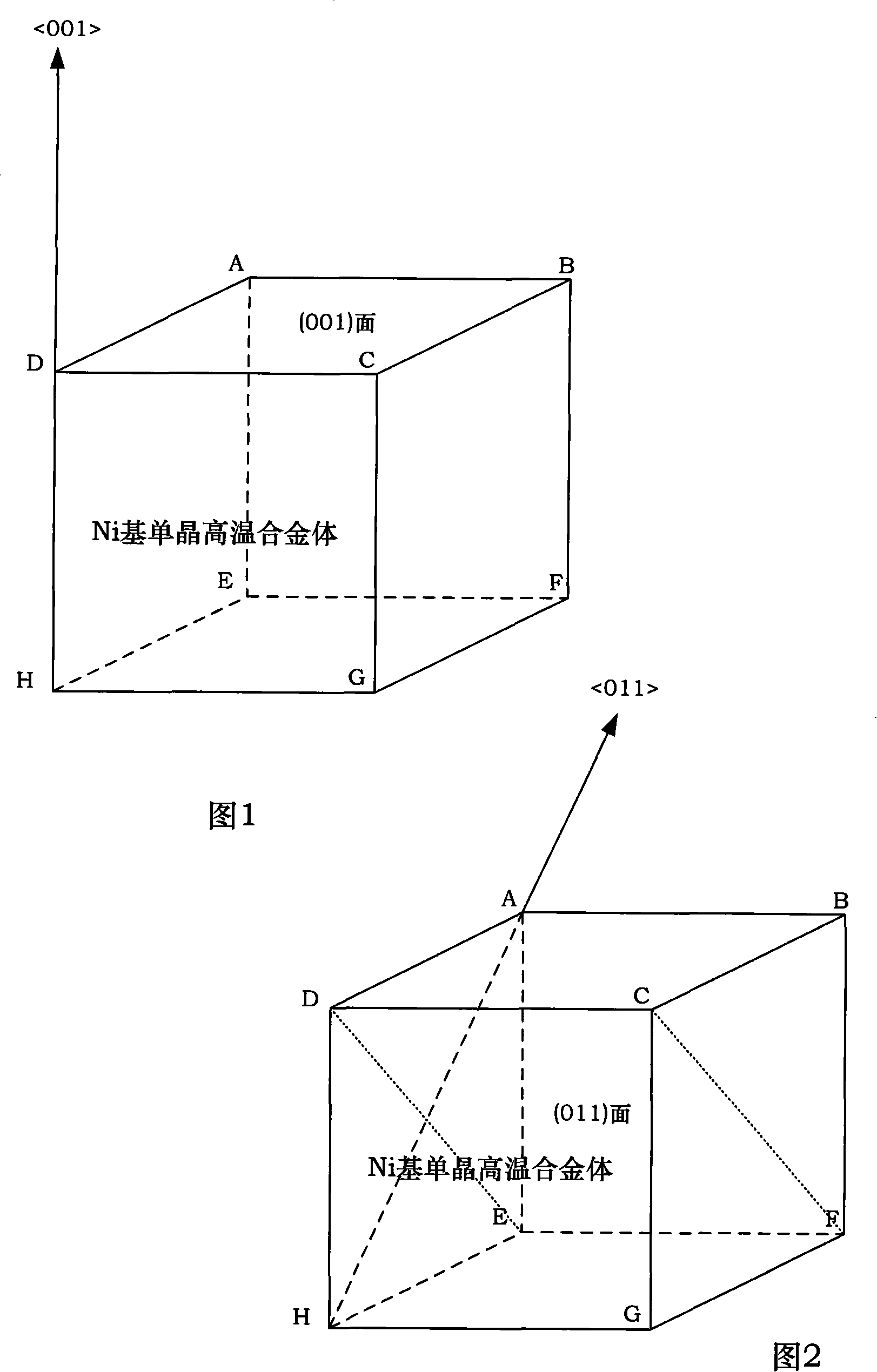

[0090] As shown in Figure 1, a test block with orientation was oriented cut on the Ni-4Cr-9Co-8W-2Mo-6Al-6.5Ta-2Re single crystal superalloy body, and the (001) plane of the test block Perform polishing treatment and surface corrosion treatment to obtain Ni-4Cr-9Co-8W-2Mo-6Al-6.5Ta-2Re single crystal superalloy seed crystal;

[0091] The (001) plane is the plane formed by four points A, B, C and D;

[0092] Polishing treatment conditions: Use 150#, 360#, 500#, 1000#, 2000# water-grinding sandpaper to polish the (001) surface of the test block, and then polish it on a polishing machine (Shanghai Precision Instrument Co., Ltd., PG-1A) deal with;

[0093] Surface corrosion treatment conditio...

Embodiment 2

[0106] The steps for preparing Ni-16Cr-8.5Co-6W-4Al-4Ti-1Ta single crystal superalloy material with orientation and excellent solidification structure are as follows:

[0107] The first step is to prepare the seed crystal of Ni-16Cr-8.5Co-6W-4Al-4Ti-1Ta single crystal superalloy;

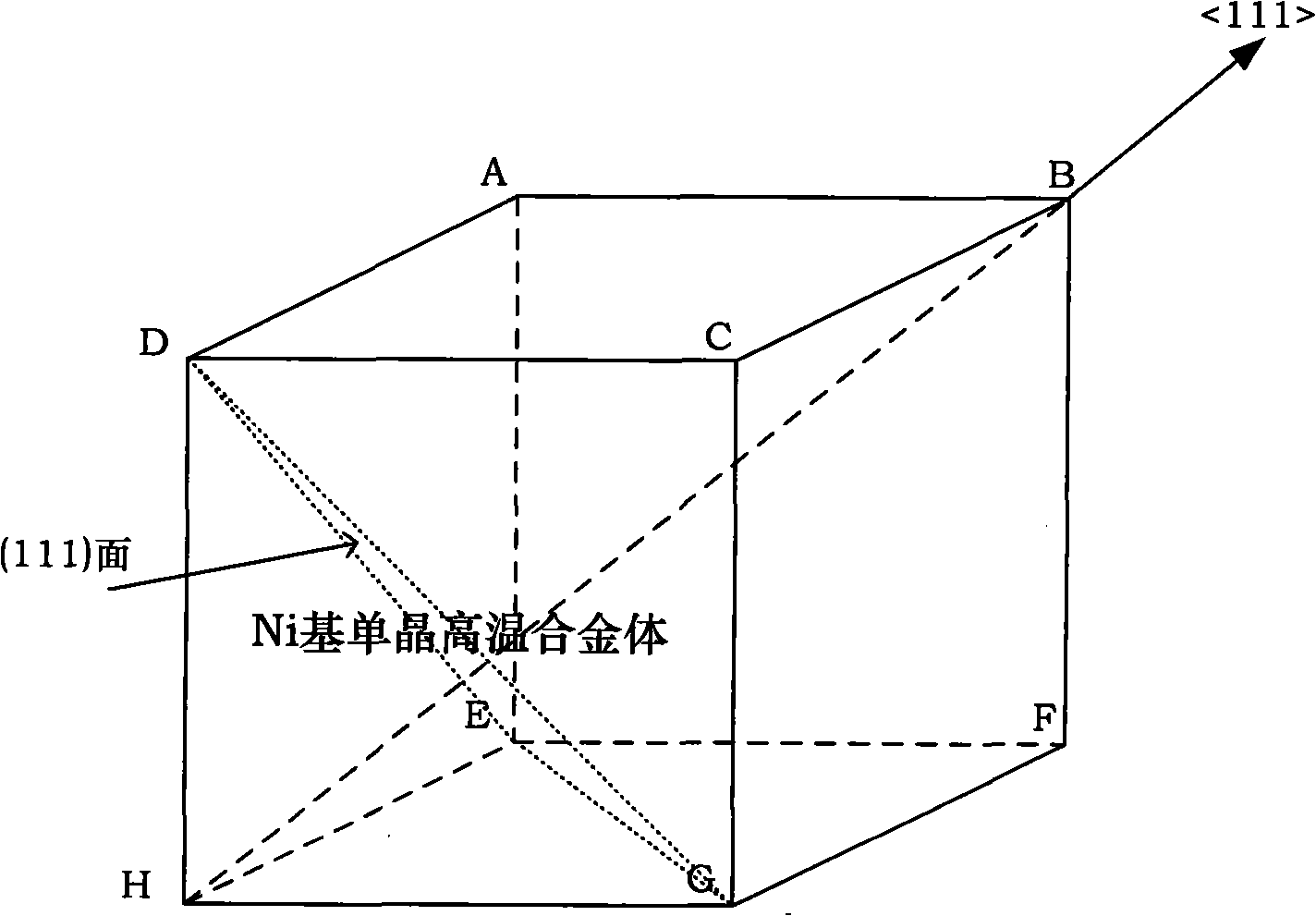

[0108] As shown in Figure 2, a test block with orientation is directional cut on the Ni-16Cr-8.5Co-6W-4Al-4Ti-1Ta single crystal superalloy body, and the (011) surface of the test block is polished Treatment and surface corrosion treatment to obtain Ni-16Cr-8.5Co-6W-4Al-4Ti-1Ta single crystal superalloy seed crystal;

[0109] The (011) plane is the plane formed by four points A, B, C and D;

[0110] Polishing treatment conditions: Use 150#, 360#, 500#, 1000#, 2000# water-grinding sandpaper to polish the (011) surface of the test block, and then polish it on a polishing machine (Shanghai Precision Instrument Co., Ltd., PG-1A) deal with;

[0111] Surface corrosion treatment conditions: the polish...

Embodiment 3

[0124] The steps to prepare Ni-9Cr-5Co-5W-4Mo-6Al-2Ti single crystal superalloy material with orientation and excellent solidification structure are:

[0125] The first step is to prepare the seed crystal of Ni-9Cr-5Co-5W-4Mo-6Al-2Ti single crystal superalloy;

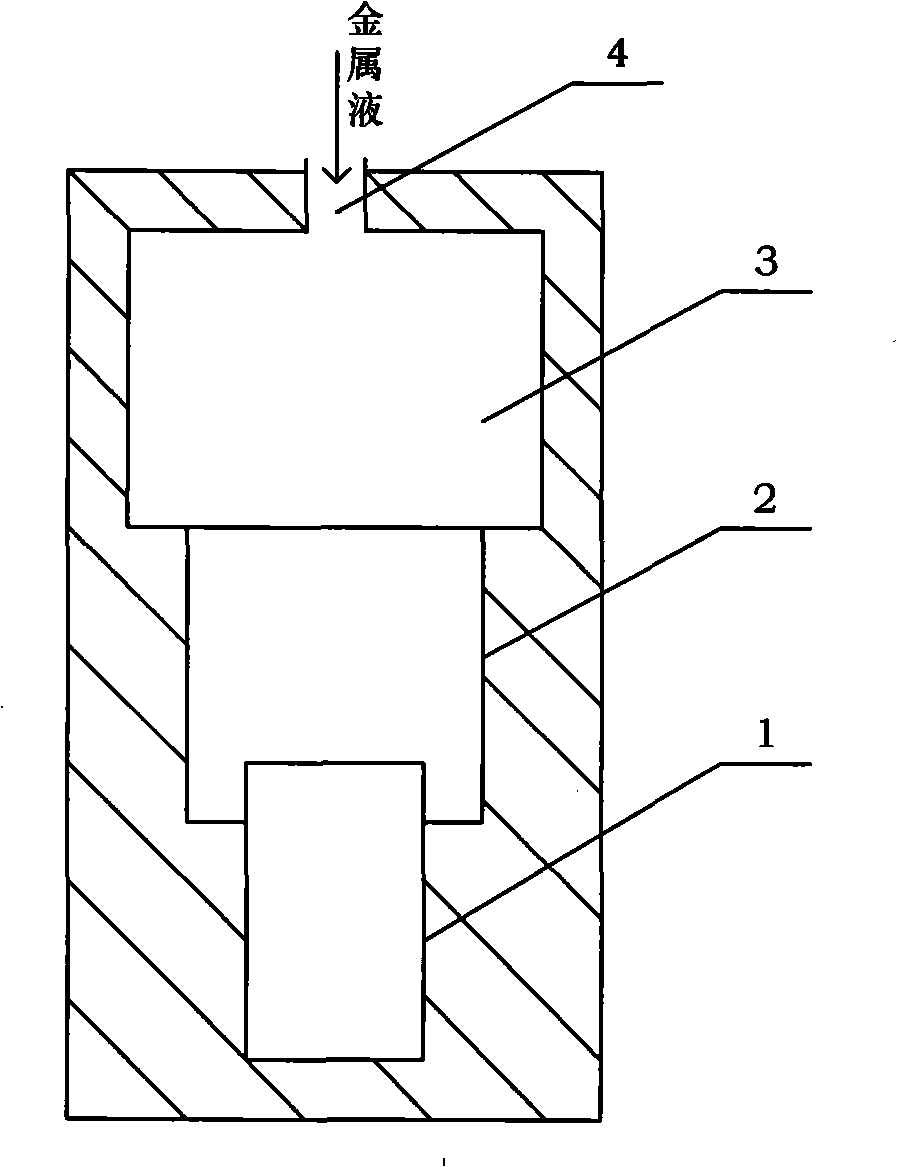

[0126] see image 3 As shown, a test block with orientation was oriented cut on the Ni-9Cr-5Co-5W-4Mo-6Al-2Ti single crystal superalloy body, and the (111) surface of the test block was polished and surface-corroded treatment to obtain Ni-9Cr-5Co-5W-4Mo-6Al-2Ti single crystal superalloy seed crystal;

[0127] The (111) plane is the plane formed by four points A, B, C and D;

[0128] Polishing treatment conditions: Use 150#, 360#, 500#, 1000#, 2000# water abrasive paper to polish the (111) surface of the test block, and then polish it on a polishing machine (Shanghai Precision Instrument Co., Ltd., PG-1A) deal with;

[0129] Surface corrosion treatment conditions: the polished test block is treated with an etchant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com