Preprocessing method for incineration of industry peril waste

A hazardous waste and pretreatment technology, applied in combustion methods, incinerators, combustion types, etc., can solve the problems of difficult incineration of industrial hazardous wastes, high treatment costs, and inability to incinerate, achieve good promotion value and market prospects, and reduce exhaust gas. The effect of purification cost and easy storage management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation is described below in conjunction with the drawings:

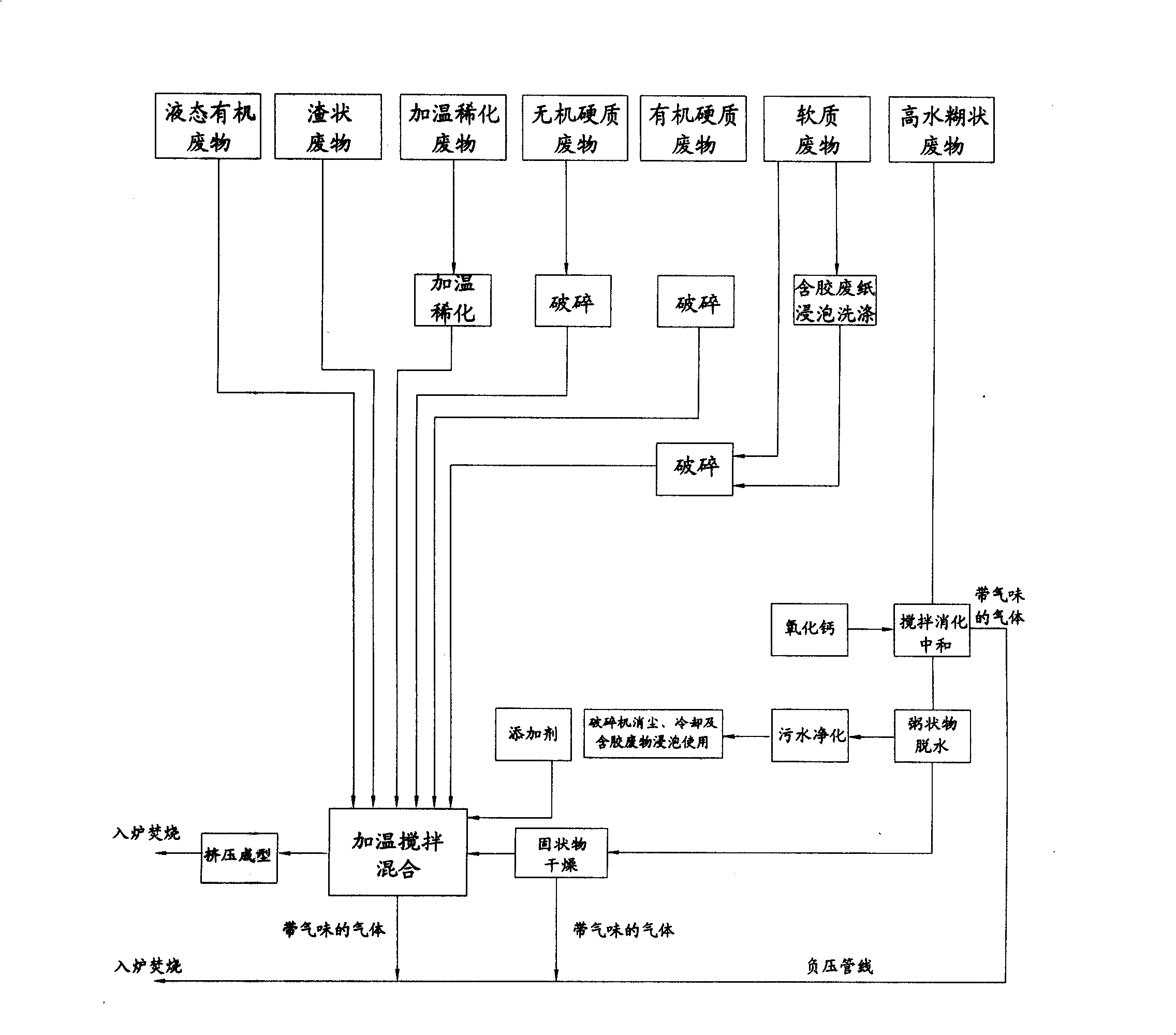

[0020] Such as figure 1 As shown, the present invention is used for the pretreatment method of industrial hazardous waste incineration. The industrial hazardous waste includes liquid organic waste, slag waste, warming and thinning waste, inorganic hard waste, organic hard waste, and soft waste. , High-water paste waste, the industrial hazardous waste is pretreated by one or more of the process steps of digestion, neutralization, separation, drying, hot melt thinning, soaking washing, and crushing. The liquid organic waste is resin glue waste; the slag waste is distillation residue waste; the warming and thinning waste is acrylic acid residue or tar waste; the inorganic hard waste is glass container Waste; the organic hard waste is waste resin or waste plastic; the soft waste is waste paper or fiber waste; the high-water paste waste is waste ink and sludge.

[0021] The specific method is to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com