Multi-medium flue gas purifying reaction tower

A flue gas purification and reaction tower technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as high infrastructure and operating costs, numerous equipment, and large site area, and reduce maintenance and downtime opportunities. , Low investment and operation cost, and the effect of small construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

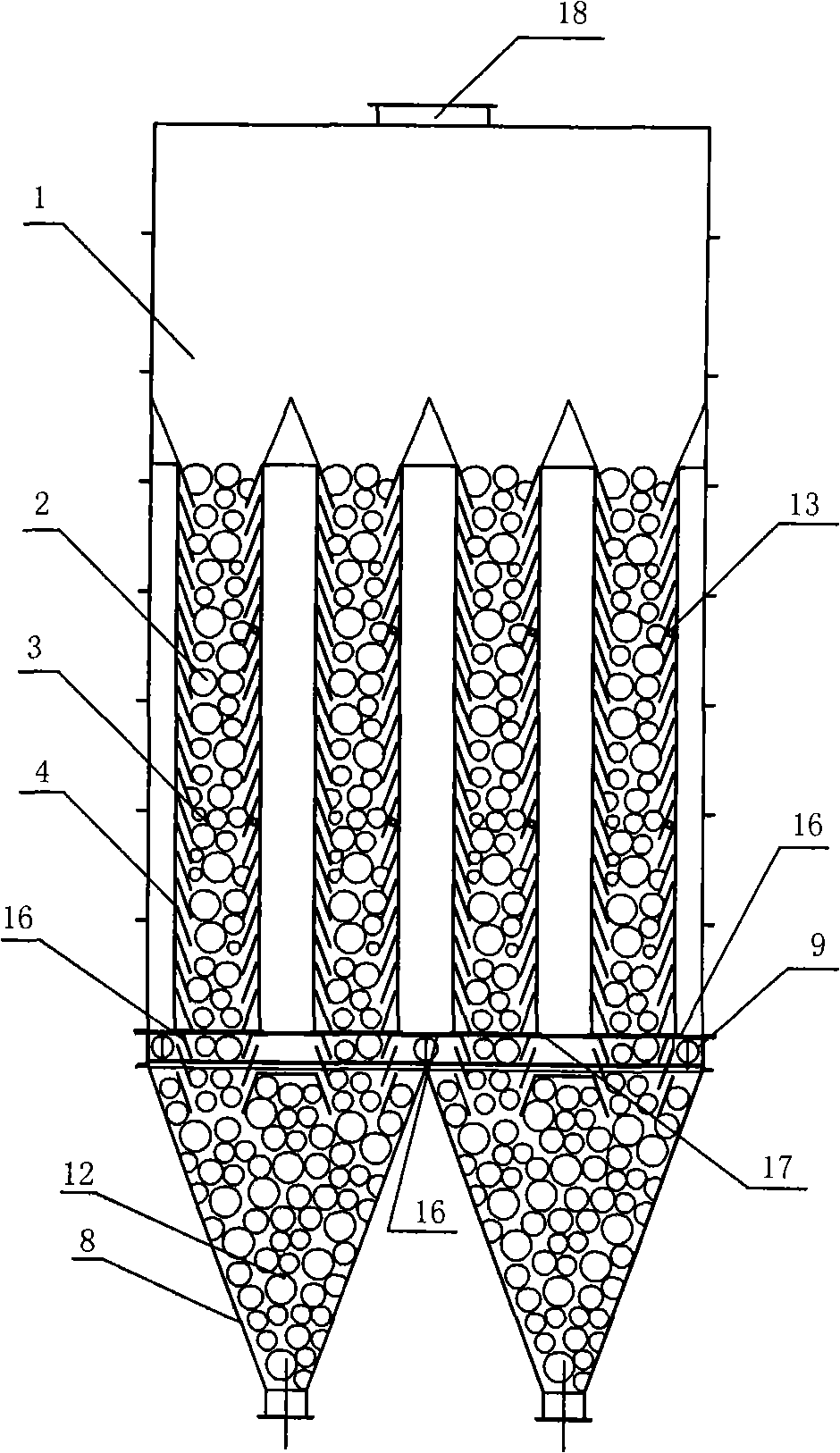

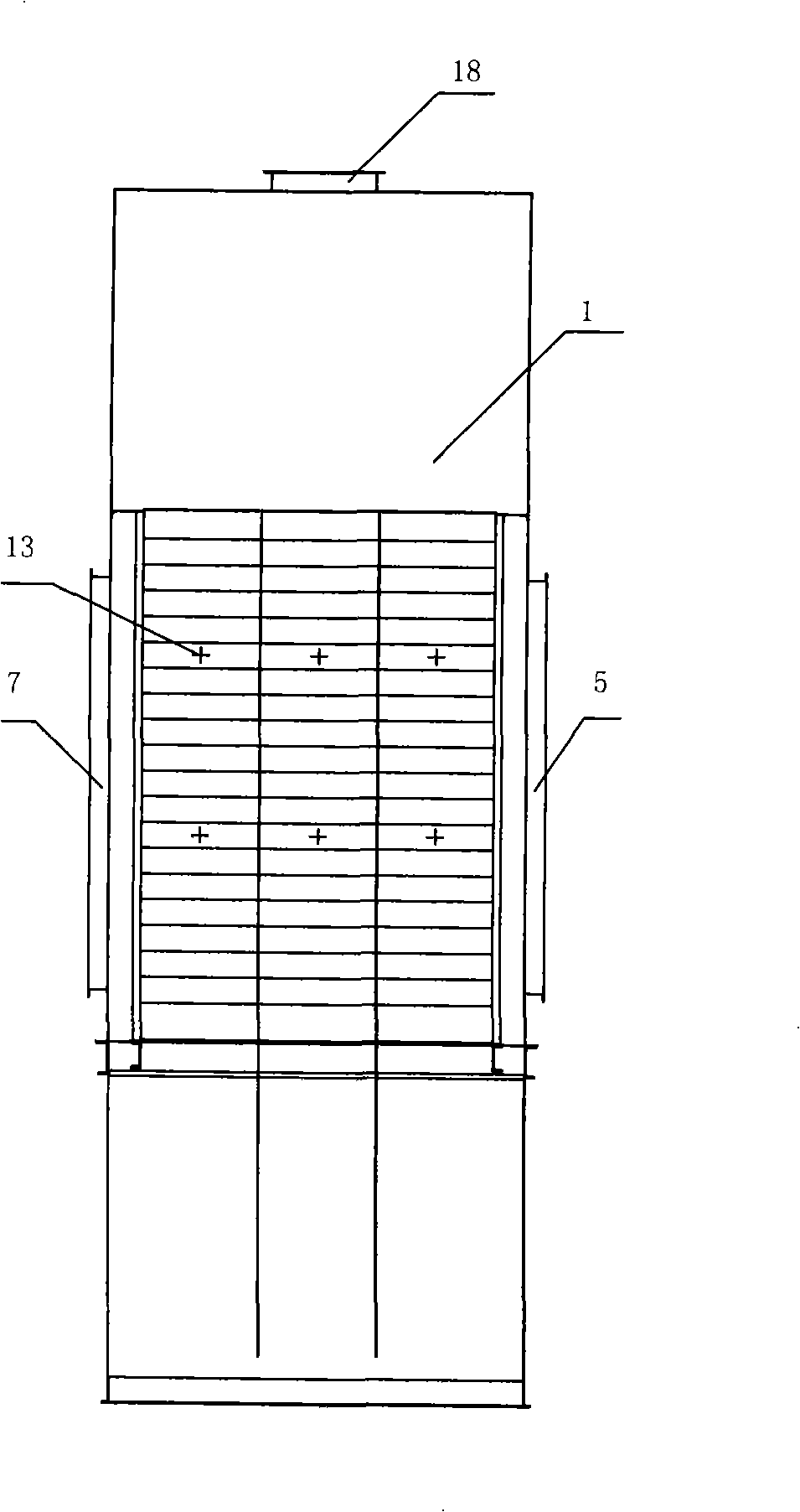

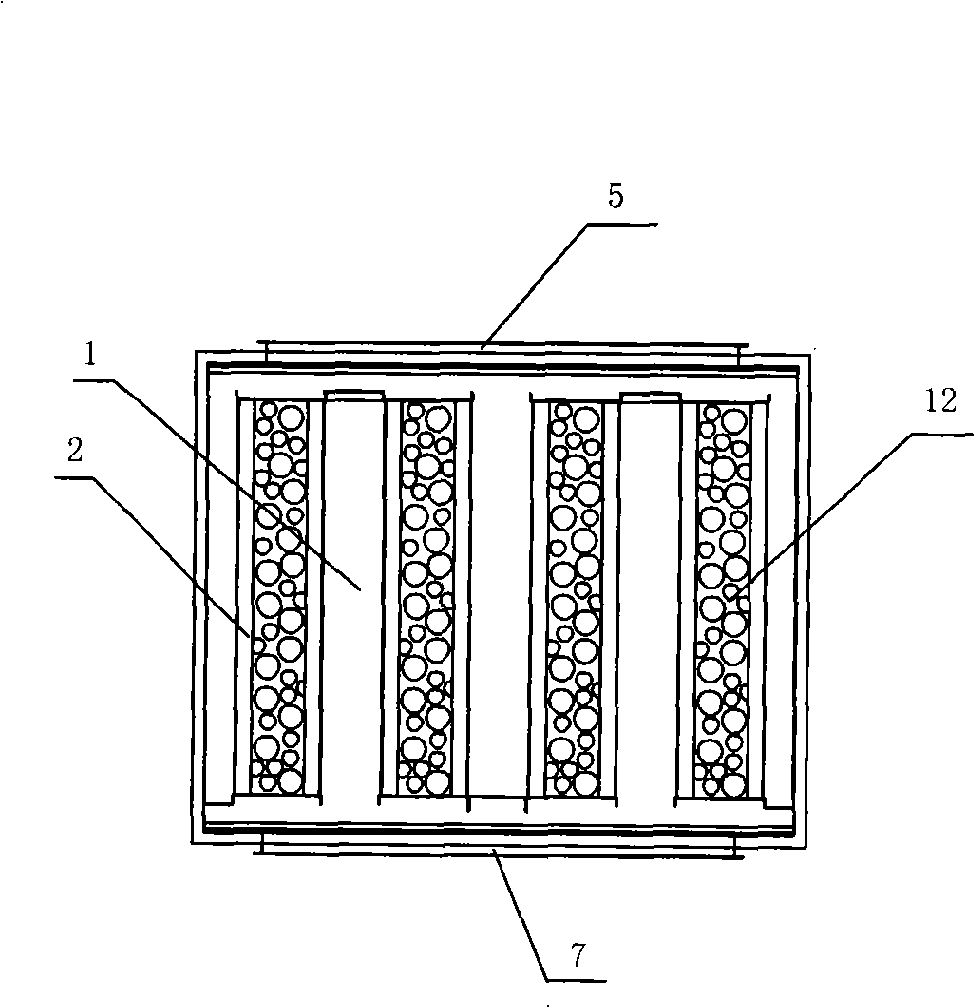

[0037] Such as figure 1 As shown, the present invention is a multi-media flue gas purification reaction tower, which is a multi-cycle, gas, liquid, and solid three-phase reaction system. The system can efficiently purify flue gas, desulfurize, denitrify, etc., and achieve clean emissions. Purpose. The multi-media flue gas purification reaction tower includes an airtight reaction tower body with an air inlet and an air outlet, such as figure 2 with image 3As shown, the air inlet 7 and the air outlet 5 of this embodiment are all located at the front and rear sides of the lower part of the reaction tower body 1, the top of the reaction tower body 1 is equipped with a feed inlet 18 for absorbent particles 12, and the bottom is equipped with an ash hopper 8, The reaction tower body 1 is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com