Method for producing composite particle slow release silicon fertilizer

A production method and composite technology, applied in the direction of fertilizer form, fertilization device, fertilizer mixture, etc., can solve the problems of complex production equipment, long production cycle, easy loss, etc., to reduce agricultural production costs, low production costs, and long production cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

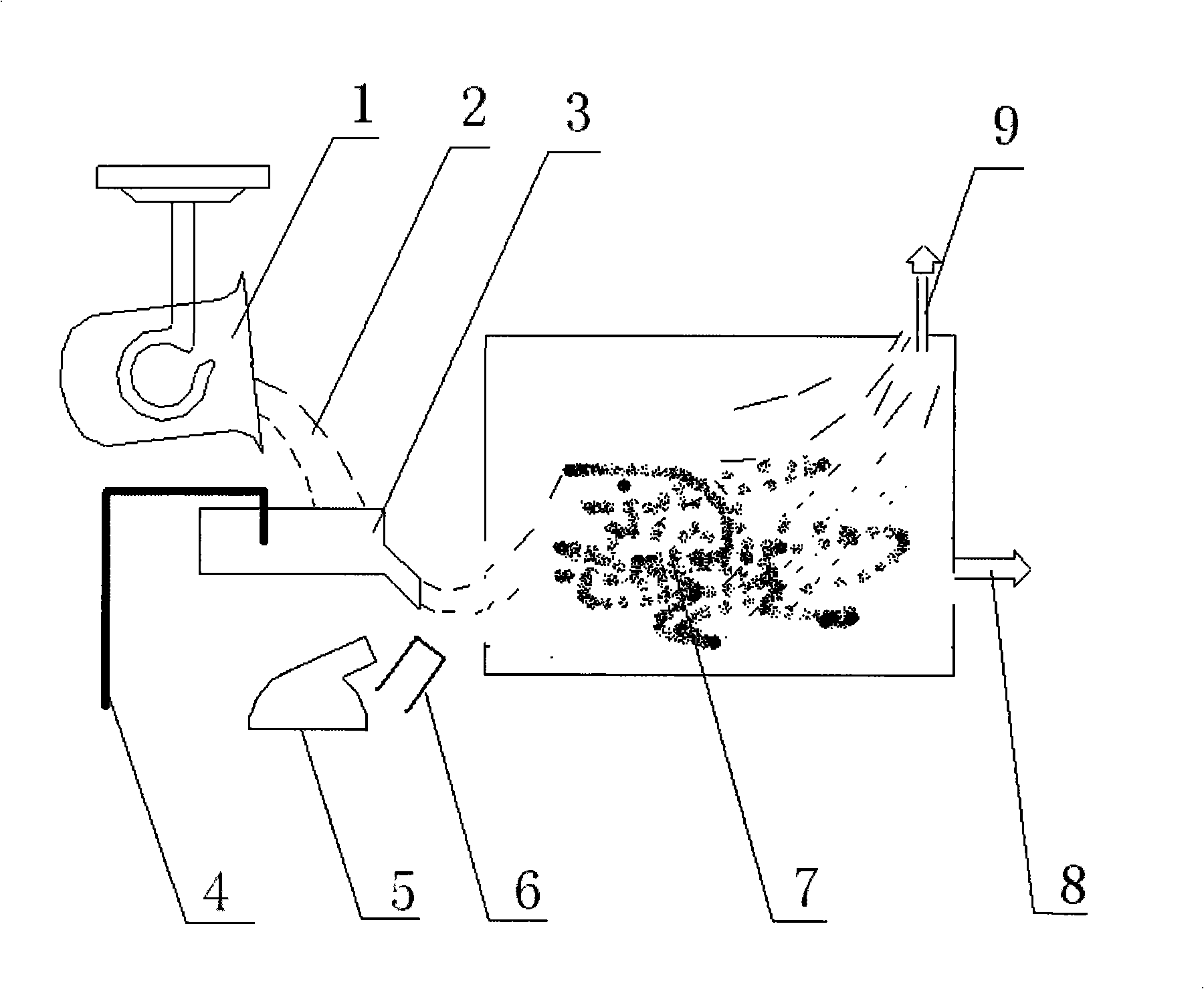

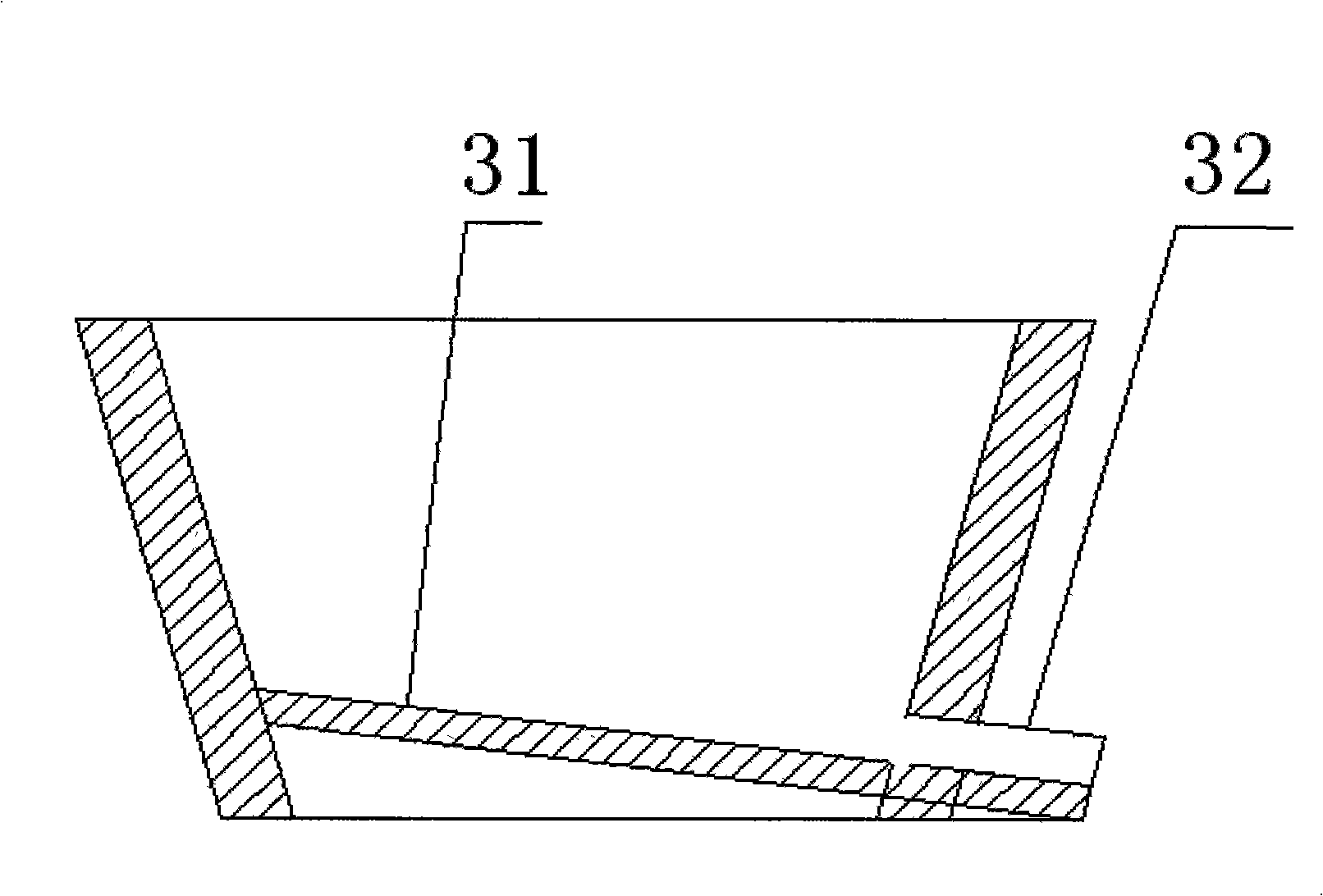

[0023] Such as figure 1 , figure 2 As shown, the liquid blast furnace slag 2 is poured from the blast furnace slag tank 1 into the tundish 3, and potassium carbonate is transported from the carbonate delivery pipe 4 to the tundish 3 at the same time. The bottom of the tundish is an inclined bottom 3, and the reaction is good. Molten silicon fertilizer utilizes gravity to flow out from outlet 31, and the molten blast furnace slag flow rate that adds in the tundish is 0.1 ton / minute, and when the silicon dioxide content is 33% in the blast furnace slag, the potash conveying capacity of regulating powder solid conveyer is 90kg / min. minute;

[0024] The lower part of the outlet 31 is provided with compressed air 5 and industrial steam 6, and the molten product is sheared by high-pressure air, and the air pressure is 4kg / cm 2 , flow 5m 3 / min, industrial steam 6 can disperse and cool the sheared molten silicon fertilizer at high temperature, and the industrial steam pressure is...

Embodiment 2

[0026] The liquid blast furnace slag 2 is poured from the blast furnace slag tank 1 into the tundish 3, and potassium carbonate is transported from the carbonate delivery pipe 4 to the tundish 3 at the same time. Fertilizer utilizes gravity to flow out from outlet 31, adds the molten blast furnace slag flow velocity 0.17 tons / min in the tundish, when the silicon dioxide content is 33% in the blast furnace slag, the sodium carbonate conveying capacity of adjusting powder solid conveyer is 90kg / min, at The lower part of the outlet 31 is equipped with compressed air 5 and industrial steam 6, and the molten product is sheared by high-pressure air, and the air pressure is 4kg / cm 2 , flow 5m 3 / minute, industrial steam 6 can disperse the sheared molten silicon fertilizer and cool it at high temperature, and the industrial steam pressure is 1.6kg / cm 2 , the flow rate is 90kg / min, and the wet granular silicon fertilizer 7 generated is dried by its own heat in the cooling chamber to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com