Method for preparing selenium-containing compound nano crystal

A technology of selenium compounds and nanocrystals, applied in the direction of selenium/tellurium compounds, binary selenium/tellurium compounds, chemical instruments and methods, etc. Problems such as poor quality and high price, achieve the effect of half-height width and narrow width, cost saving, and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

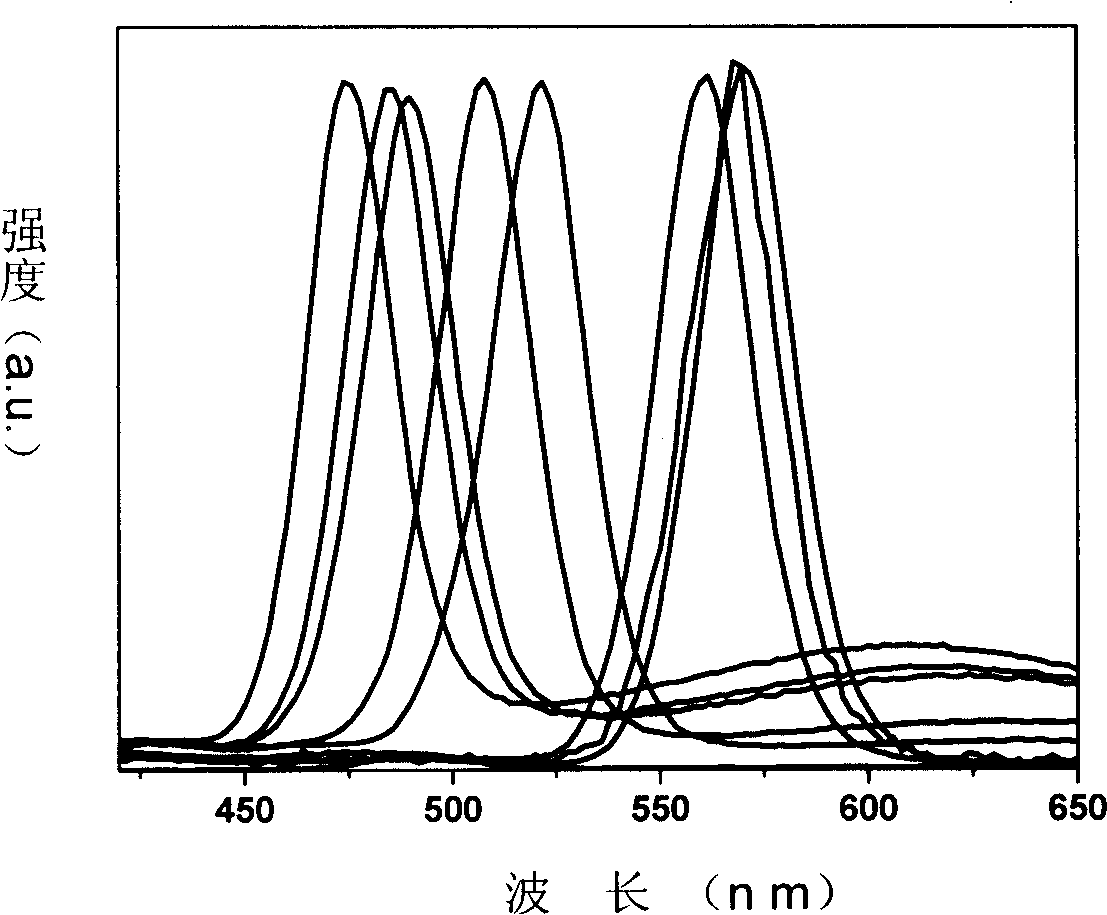

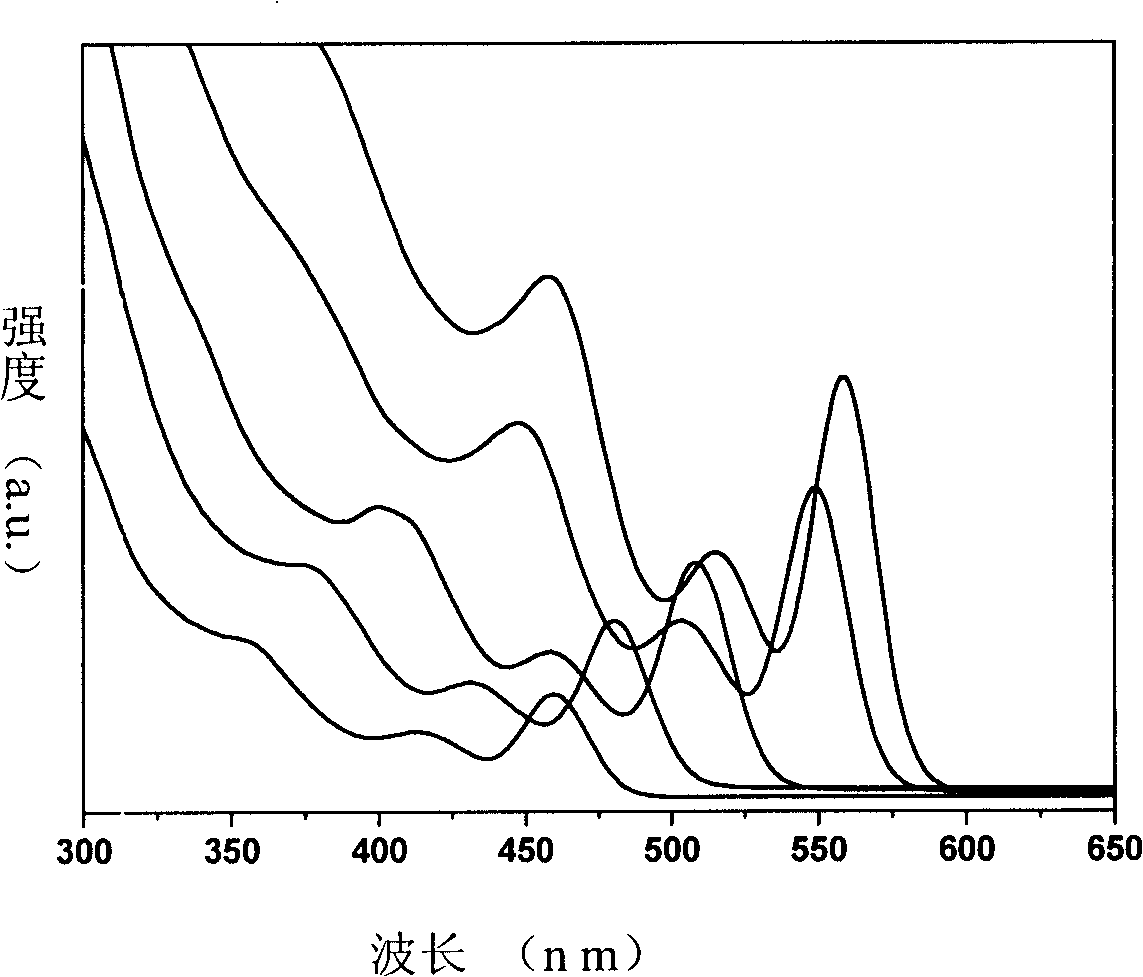

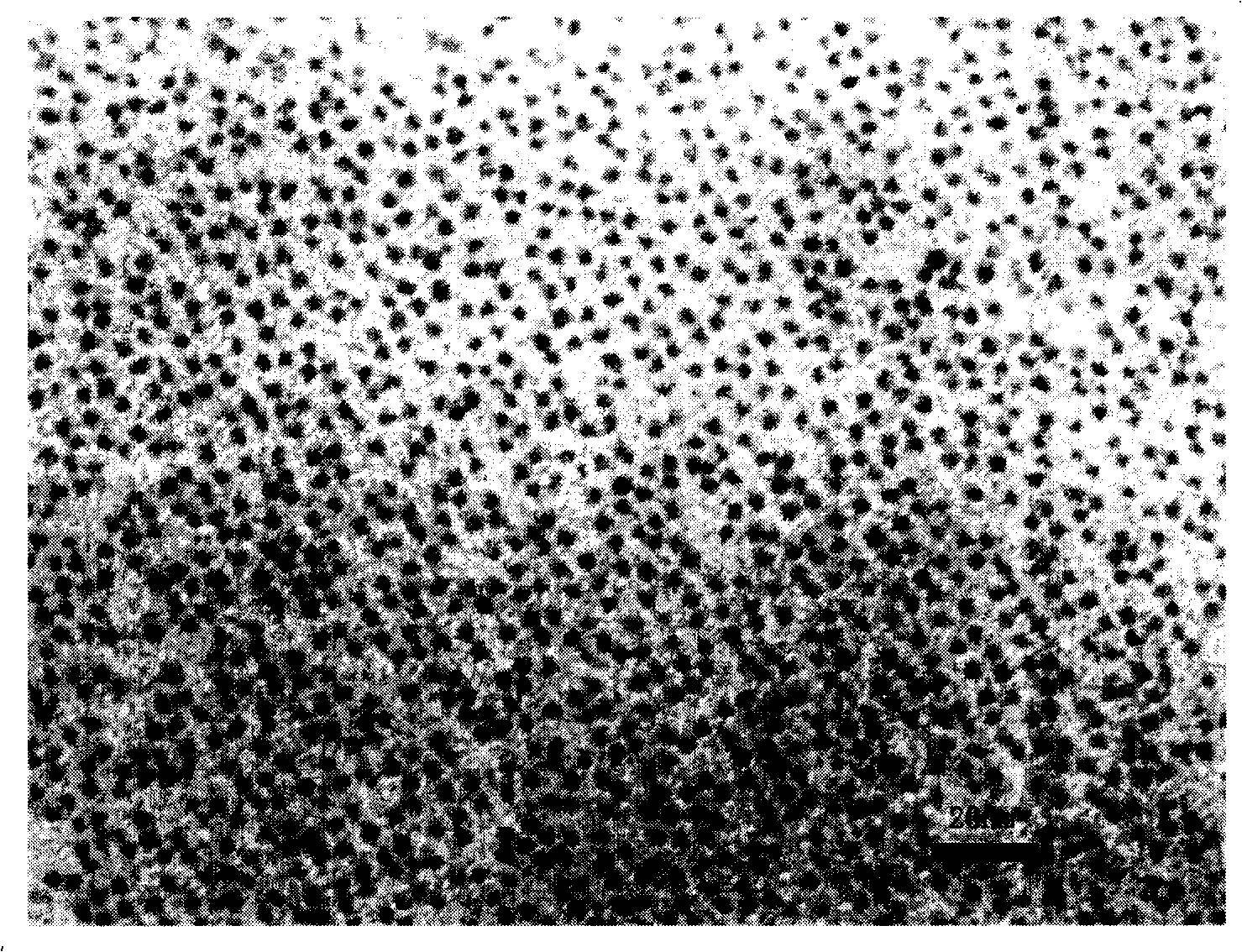

[0021] Take 0.12mmol of cadmium oleate, 0.24mmol of octadecylamine, and 4g of octadecene, mix them into a 25mL three-neck bottle, and heat to 280°C under a nitrogen atmosphere until the solution is completely uniform; mix 1.2mmol of Se powder, 3.6mmol of octadecylamine and 10ml Octadecene is mixed and heated at 220°C to obtain a light yellow selenium precursor solution. Take 2mL of selenium precursor solution and quickly inject it into a three-necked bottle, and then lower the temperature to 260°C for growth. The solution is colorless when it is first injected, and then gradually turns into light yellow, yellow, light red, red, deep red, dark red, and the reaction time is three hours. When the solution is of different colors, CdSe nanocrystals of different sizes can be obtained. . The solutions of different colors were sampled for fluorescence spectrum and absorption spectrum test, and the fluorescence peak changed from 470nm to 650nm. Fluorescence spectrum such as figure 1 ...

Embodiment 2

[0023] Take 0.12mmol of cadmium oxide, 0.3mmol of oleic acid, and 3.8g of octadecene and mix them into a 25mL three-neck bottle, and heat to 260°C under a nitrogen atmosphere until the solution is completely uniform; mix 1.2mmol of Se powder, 3.6mmol of octadecylamine and 10ml of Decene was mixed and heated at 220°C to obtain a light yellow selenium precursor solution. Take 3mL of selenium precursor solution and inject it into the three-necked bottle quickly, and then lower the temperature to 240°C for growth. The solution is colorless when it is just injected, and then gradually turns into light yellow, yellow, light red, red, deep red, dark red, and the reaction time is two hours. When the solution is of different colors, CdSe nanocrystals of different sizes can be obtained. . The solutions of different colors were sampled for fluorescence spectrum and absorption test, and the fluorescence peak changed from 470nm to 620nm.

Embodiment 3

[0025] Take 0.12mmol of cadmium stearate, 1.2mmol of octadecylamine, and 5g of tetradecane and mix them into a 25mL three-neck bottle, and heat to 240°C under nitrogen until the solution is completely uniform; mix 1.2mmol of Se powder, 3.6mmol of oleic acid and Mix 10ml of liquid paraffin and heat at 220°C to obtain a light yellow selenium precursor solution. Take 4mL of selenium precursor solution and quickly inject it into a three-necked bottle, then lower the temperature to 260°C for growth. The solution is colorless when it is first injected, and then gradually turns into light yellow, yellow, light red, red, deep red, dark red, and the reaction time is three hours. When the solution is of different colors, CdSe nanocrystals of different sizes can be obtained. . The solutions of different colors were sampled for fluorescence spectrum and absorption test, and the fluorescence peak changed from 470nm to 650nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com