Method for extracting raffinose from cottonseed scum

A technology of raffinose and cottonseed meal, which is applied in chemical instruments and methods, oligosaccharides, sugar derivatives, etc., can solve the problems of difficulty in extraction and utilization of raffinose, low quality of cottonseed meal, environmental impact, etc., and achieves easy operation. , the effect of reducing content and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The extraction method of the present invention will be specifically described below with the case of processing 150 tons of high-quality cottonseed per day.

[0028] The yield of cottonseed oil is 15-20%, the yield of dephenolized cottonseed meal is 37-42%, the yield of rough raffinose is 0.5-1.0%, and the yield of refined raffinose is 0.3-0.8%.

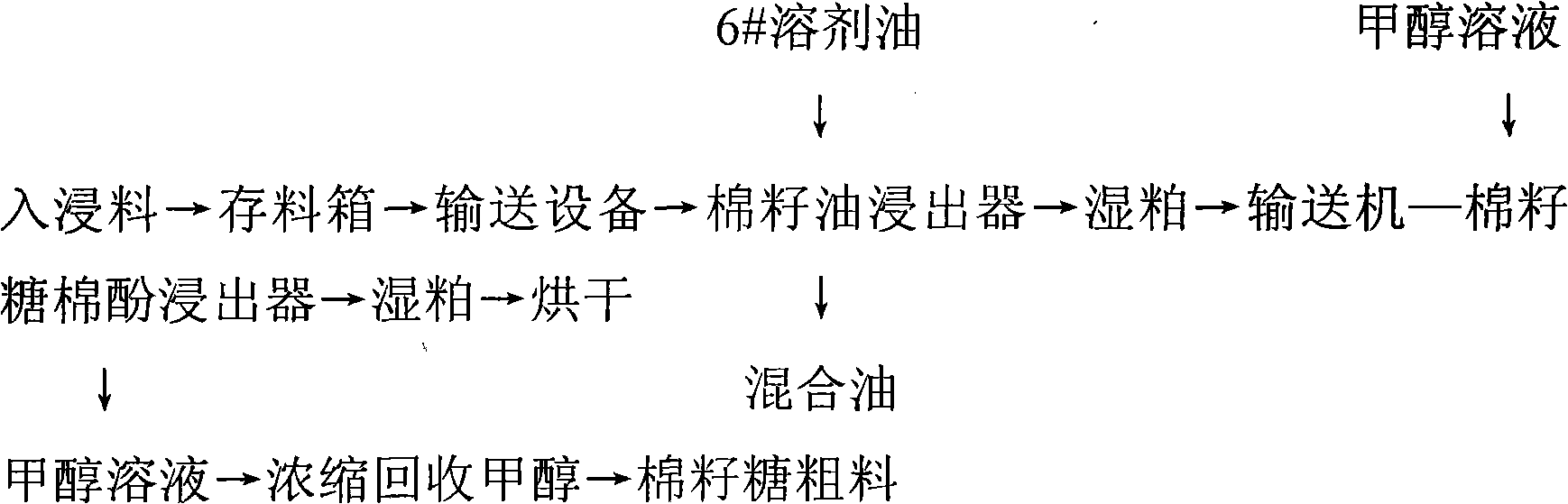

[0029] Process 150 tons of high-quality cottonseed per day to obtain 22.5-30 tons of cottonseed oil, 55.5-63 tons of dephenolized cottonseed meal, 0.75-1.50 tons of rough raffinose, and 0.45-1.2 tons of refined raffinose. The extraction steps are divided into pretreatment of cottonseed, leaching and refining.

[0030] 1. Pretreatment

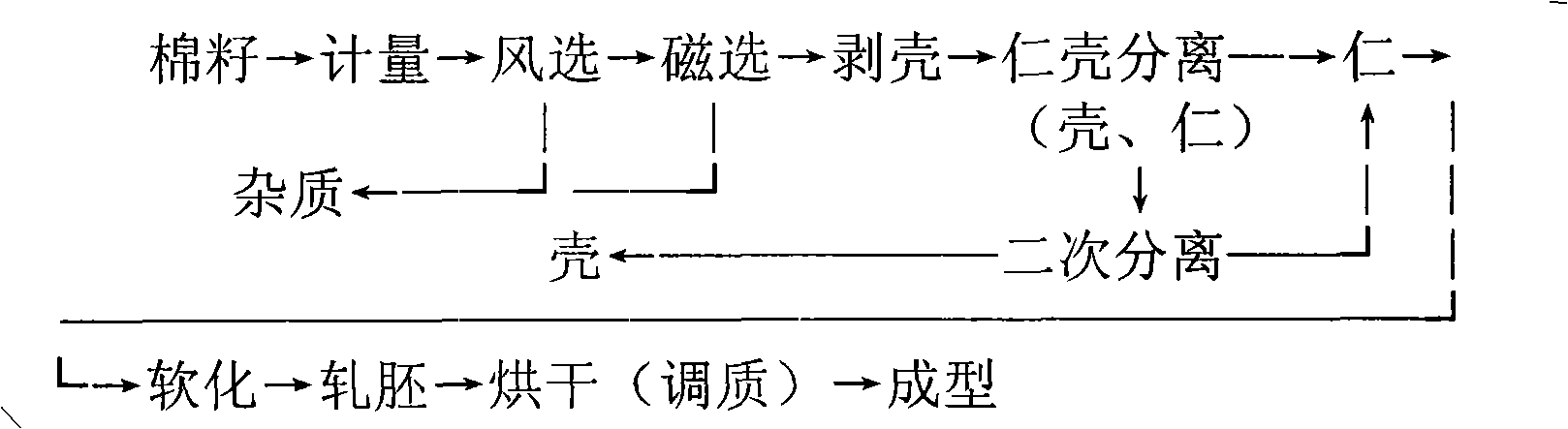

[0031] process such as figure 1 As shown, the technical requirements for pretreatment are as follows:

[0032] 1. Cottonseed contains impurities ≤ 0.5% after cleaning, cottonseed scraps contain oil ≤ 0.5%

[0033] 2. After the cottonseed is peeled and separated, the kernel content in the she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com