Method and device for preparing polypara-phthaloyl para-phenylene diamine resin

The technology of poly-p-phenylene terephthalamide and p-phenylenediamine is applied in the field of preparation of poly-p-phenylene terephthalamide resin, and can solve the problem of low product quality, difficult reaction control, and easy generation Gel and other problems, to achieve the effect of high surface renewal rate, high heat transfer capacity, and avoiding fouling residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

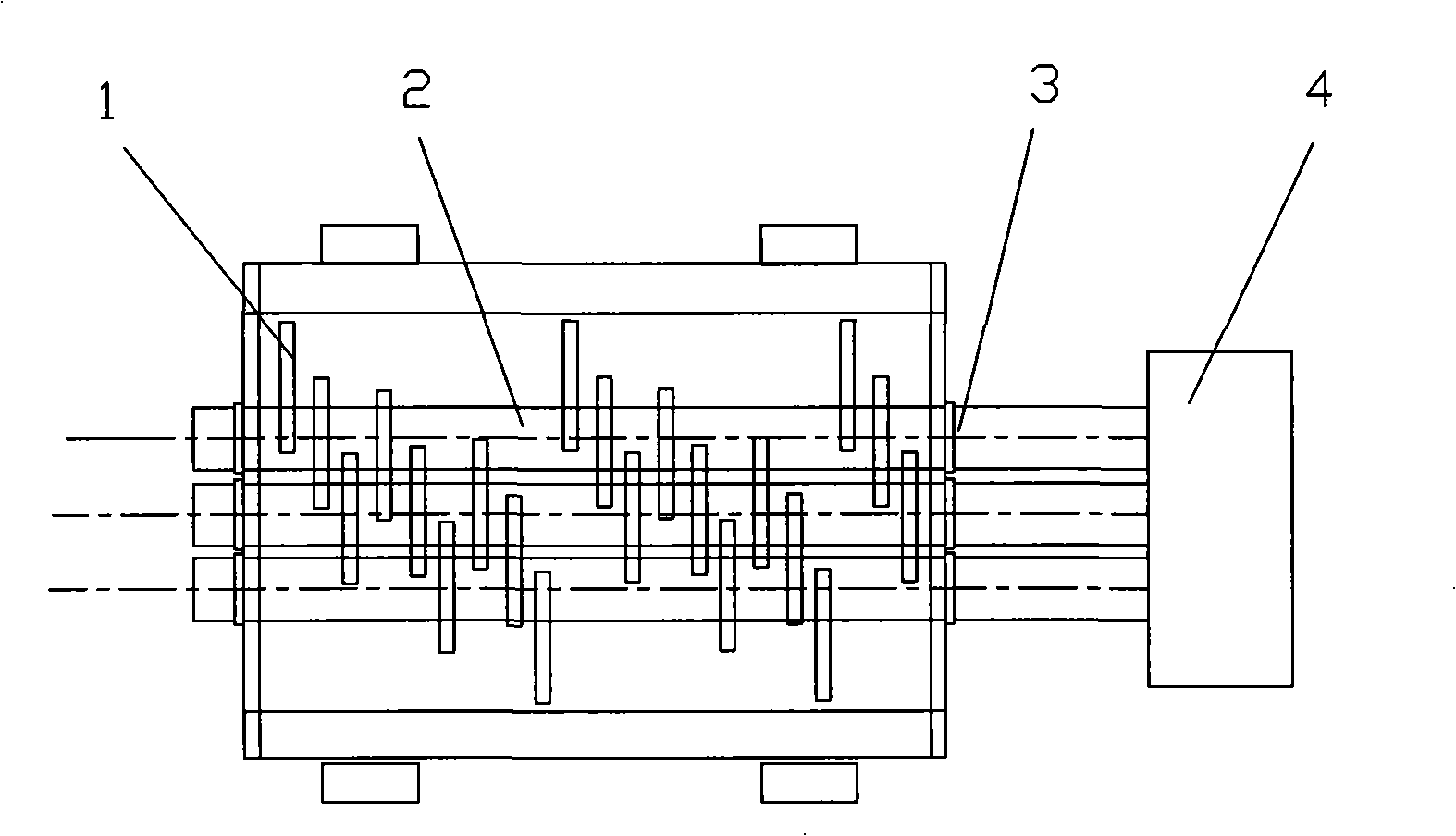

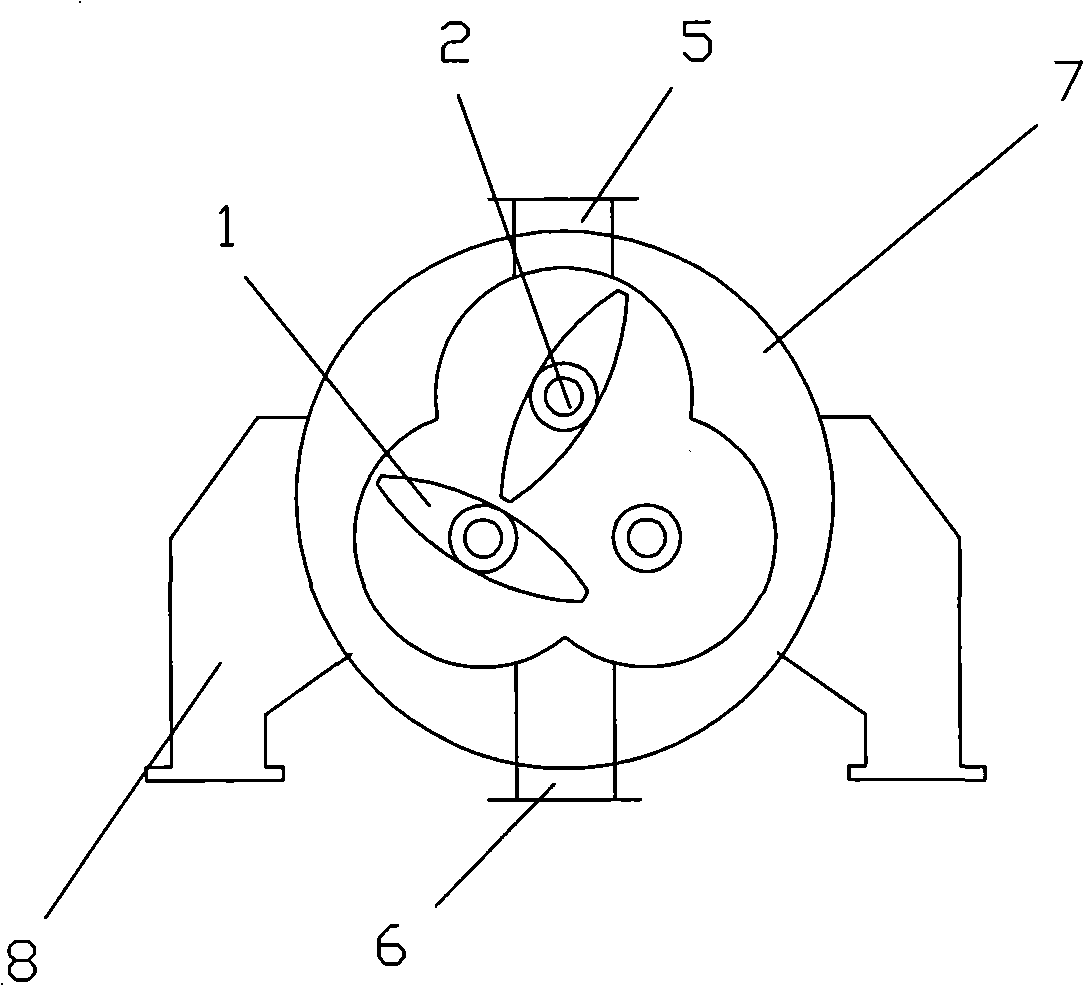

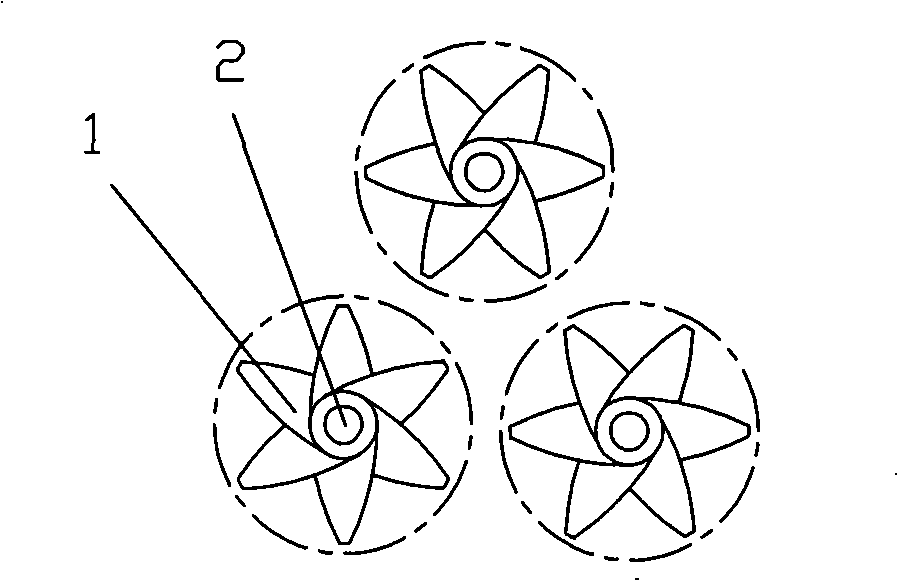

[0035] The structure of the three-axis self-cleaning pre-reactor is shown in the figure. The three shafts 2 are connected to the driving device 4 in the shape of a pin, and several blades 1 are respectively staggeredly installed on the shaft 2 and sealed in the cylinder 7 by the shaft seal 3. Among them The vane 1 and the shaft 2 are hollow and interpenetrated; there is a cavity between the outer wall of the cylinder and the inner wall of the cylinder; the support 8 is connected to the cylinder 7; the material inlet 5 connects the upper part of the cylinder 7 with the inner wall of the cylinder and the shaft The reaction chamber formed by the seal 3 communicates, and the material outlet 6 communicates with the reaction chamber from the bottom of the cylinder 7 . There are small gaps between the blades 1 on the three shafts and between the blades and the inner wall of the cylinder 7, so that materials on the blades and the inner wall of the cylinder can be scraped when stirring ...

Embodiment 2

[0037] Add 30Kg of anhydrous N-N dimethylacetamide into a 50L jacketed stainless steel pre-reaction kettle, add 2Kg of anhydrous magnesium chloride activated by high temperature, after the dissolution is completed, add 1.3Kg of p-phenylenediamine to fully dissolve it into solution, cooled to -15°C for later use. Continuously add 2.5Kg of powdered terephthaloyl chloride at 20.8g / min by using a weight-loss type continuous metering electronic balance, and pass through the stirring equipment of the heat transfer medium with the help of specially designed blades, shafts and jackets (three-axis self-cleaning pre-reaction device) to keep the temperature of the system at -15 to 35°C, the inherent viscosity of the prepolymer is controlled at 1.67dl / g, and the prepolymer and α-picoline are controlled at 290g / min and 7g / min respectively The flow is fed into a twin-screw extruder with a diameter of ∮35, an aspect ratio of 48, and a speed of 150rpm at the same time by a metering pump. The ...

Embodiment 3

[0039] Add 30Kg of anhydrous N-methylpyrrolidone (NMP) in a 50L stainless steel pre-reaction kettle with a jacket, add 2Kg of anhydrous calcium chloride activated by high temperature, after completing the dissolution, add 1.3Kg of p-phenylenediamine to make it Fully dissolved to form a solution, cooled to -15°C for later use. Continuously add 2.5Kg of powdered terephthaloyl chloride at 14.8g / min by using a weight-loss type continuous metering electronic balance, and pass through the stirring equipment of the heat transfer medium with the help of specially designed blades, shafts and jackets (three-axis self-cleaning pre-reaction The heat exchange method of the device) keeps the system temperature at -15~35°C, the inherent viscosity of the prepolymer is controlled within the range of 1.86dl / g, and the flow rates of the prepolymer and pyridine are 150g / min and 3g / min respectively. The metering pump is added to the twin-screw extruder with a diameter of ∮35, an aspect ratio of 48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inherent viscosity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com