Large working capability finite corner DC moment electric motor location drive module

A technology of DC torque motor and limited rotation angle, which is applied in the direction of electric controller, machine/engine, electrical control, etc. It can solve the problem of not meeting the requirements of diesel engine speed regulation control, difficult to guarantee real-time control law, poor dynamic characteristics and anti-interference ability To achieve the effect of improving safety protection function, improving anti-load interference ability, enhancing adaptability and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in more detail below in conjunction with accompanying drawing example:

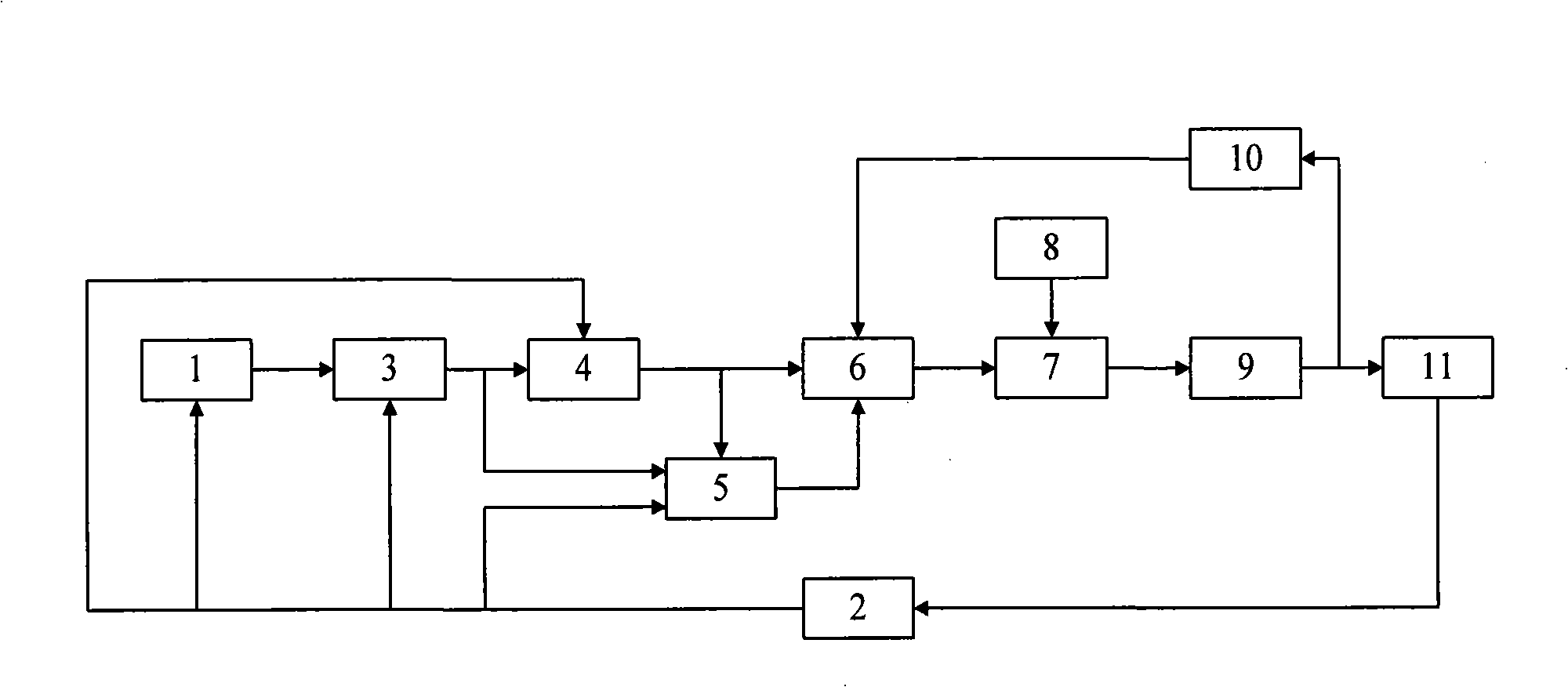

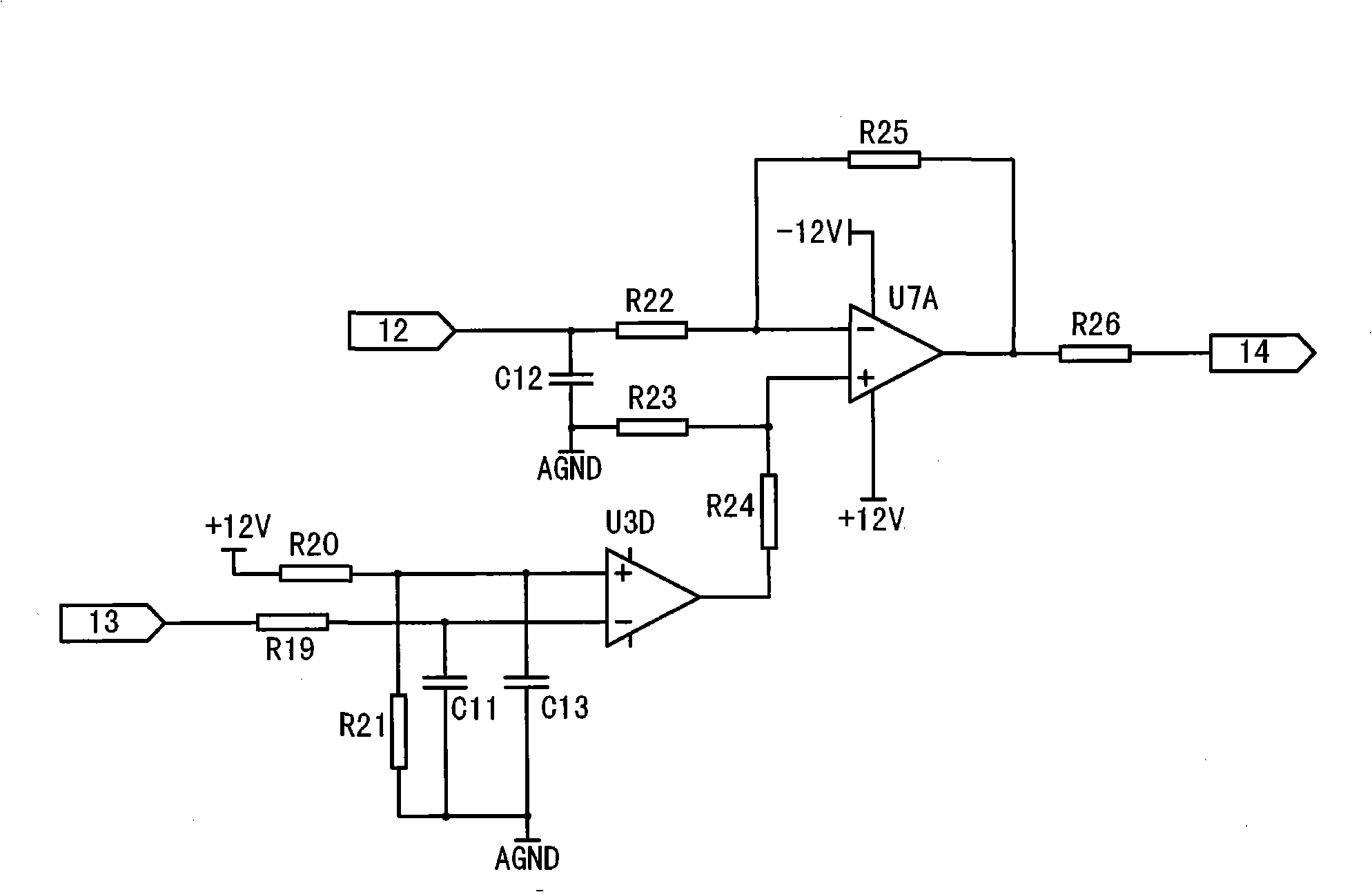

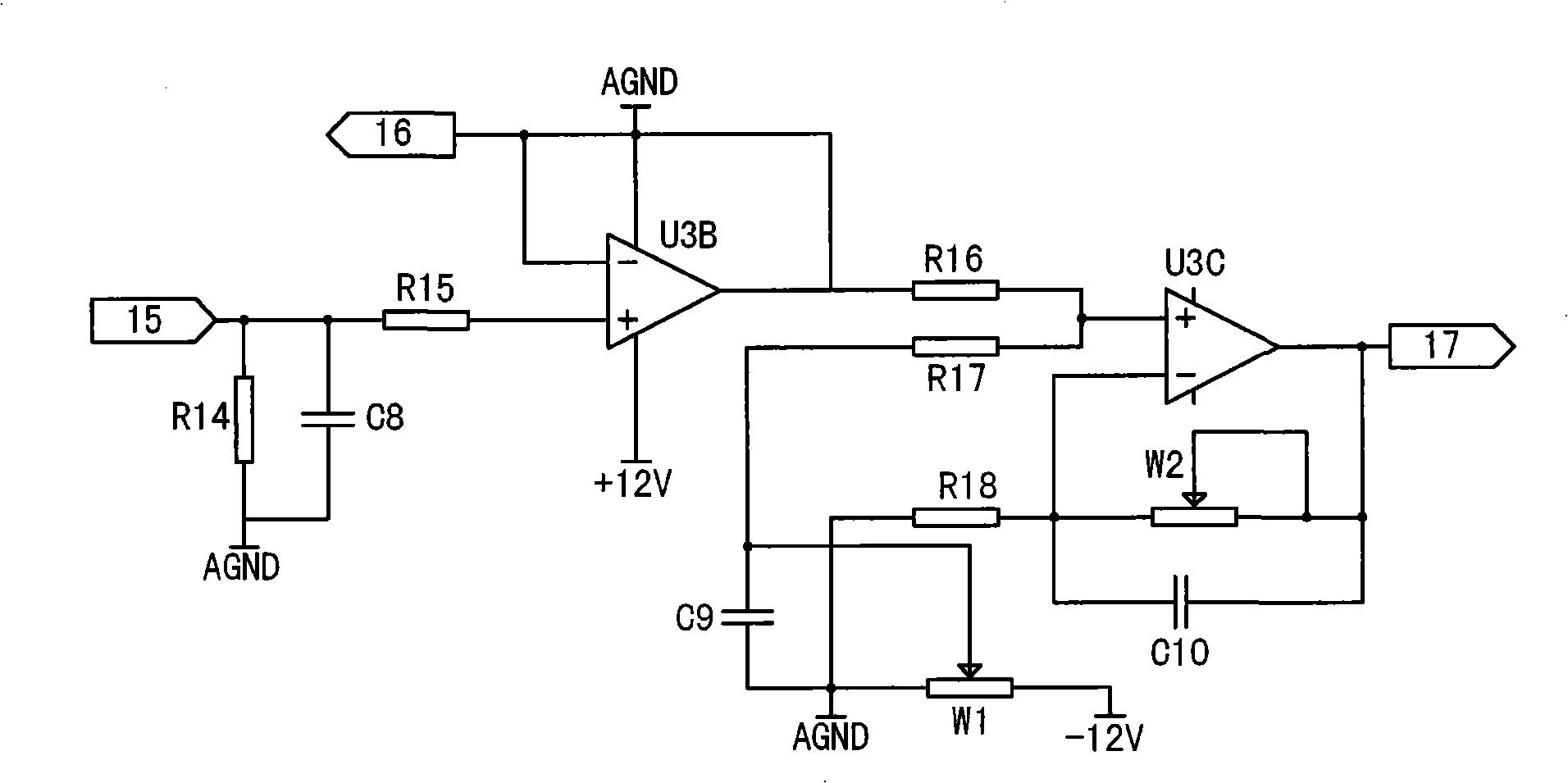

[0033] combine figure 1, the position drive module structure of the large working capacity limited rotation angle DC torque motor of the present invention includes: a rotation angle position setting and sensor failure protection circuit 1, a rotation angle position detection and conditioning circuit 2, a rotation angle position PID controller circuit 3, and an angular velocity PI controller circuit 4. Angular acceleration PI controller circuit 5, current PI controller circuit 6, PWM conversion circuit 7, triangular wave generator circuit 8, logic H-bridge power drive circuit 9, current detection circuit 10, and limited rotation angle DC torque motor 11. Corner position detection and conditioning circuit 2 collects and detects the position signal of the limited-angle DC torque motor 11, and inputs it to the corner position setting and sensor failure protection circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com