A tube phase change memory unit structure and its making method

A technology of phase-change memory and cell structure, which is applied in the field of microelectronics and can solve the problems of large peripheral circuits, large operating current, and large power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

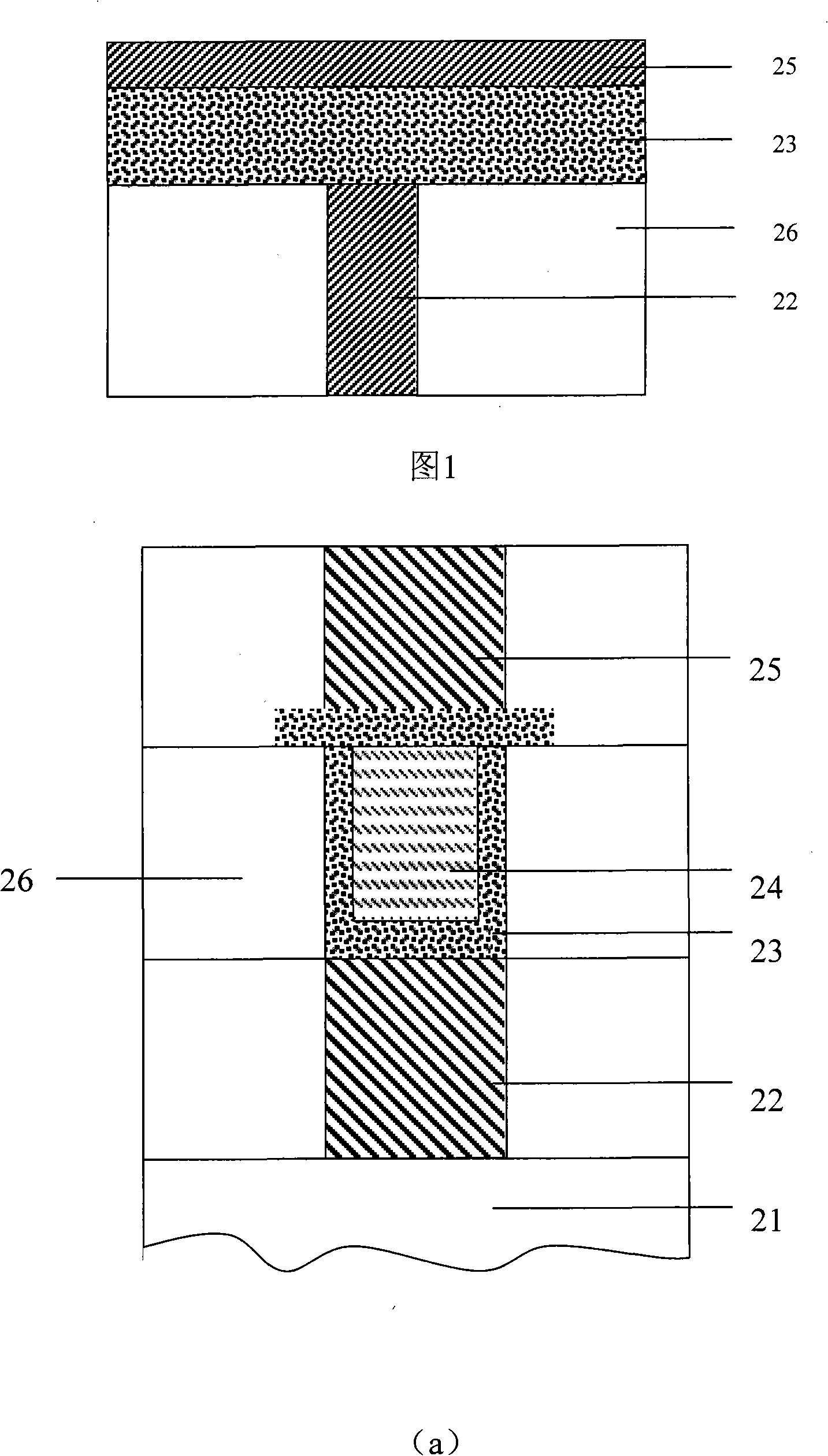

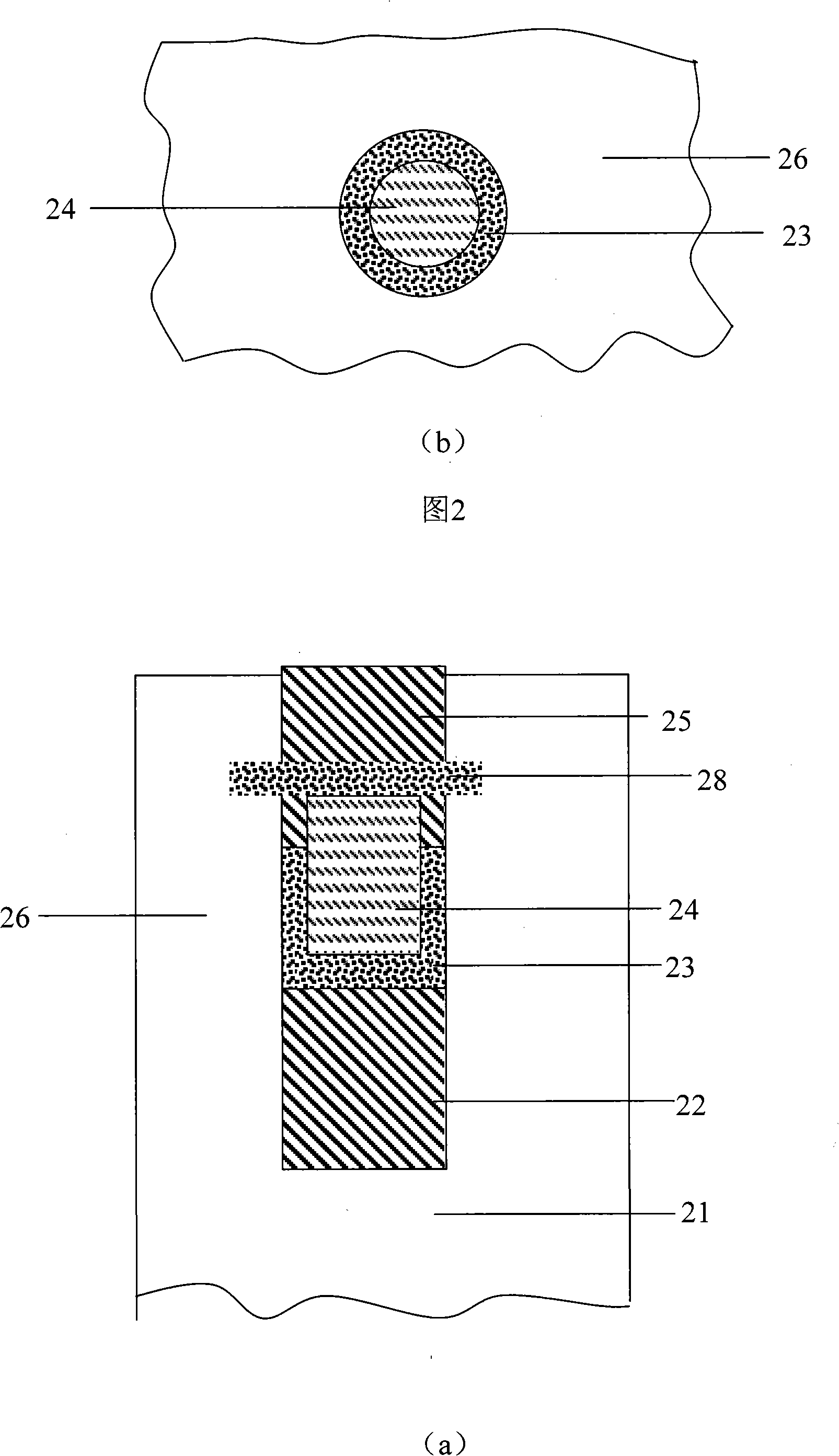

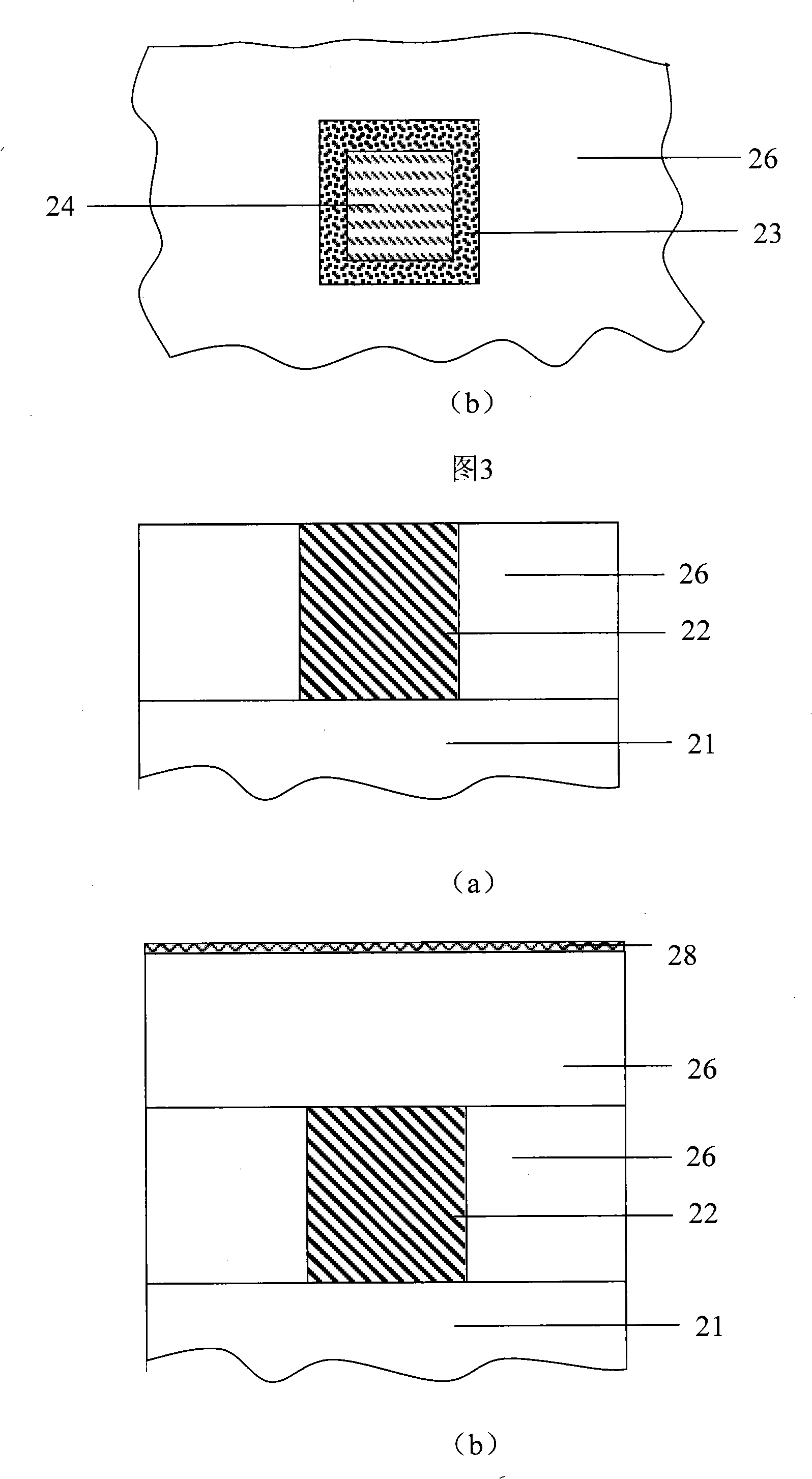

[0018] The invention is described more fully below with reference to the drawings, which provide preferred embodiments but should not be considered limited to the embodiments set forth herein. In the drawings, the thicknesses of layers and regions are exaggerated for clarity, but as schematic diagrams, they should not be considered as strictly reflecting the proportional relationship of geometric dimensions. Here, the referenced figures are schematic views of the present invention, and the representations in the figures are schematic, but should not be considered as limiting the scope of the present invention.

[0019]Figure 4 (a)-(f) illustrate methods of forming certain embodiments of the present invention. The following is a further introduction to the operation steps of preparing this ring-shaped phase-change memory unit in combination with the diagrams:

[0020] 1. If Figure 4 (a) As shown in the substrate (including the MOS impurity diffusion region, source and drain r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com